Why us

Why customers choose WUZHOU

Precision Engineering in Spiral Welding Pipe Manufacturing

CangLuo Group is one of China’s leading manufacturers of spiral welded steel pipes. Established in 1993, the company has specialized in spiral steel pipe production for 32 years, accumulating extensive industry experience.

As a Top 10 Chinese Brand of Steel Pipe, CangLuo Group has received multiple prestigious awards, including the AAA Credit Rating Enterprise. Our high-quality spiral welded steel pipes are exported to numerous countries and widely trusted in major petroleum, gas, water, and infrastructure projects worldwide.

Unmatched Quality

WUZHOU delivers superior spiral steel pipes with spiral submerged arc welding process.

Comprehensive Range

We provide a wide selection of spiral steel pipes for various specifications.

Our products are available in a wide range of sizes and can be customized

Our products are available in a wide range of sizes, with diameters ranging from 219mm to 3500mm and wall thicknesses from 6mm to 26mm. This variety allows us to cater to diverse industry needs, including those in petroleum, gas, water, and infrastructure projects.

Extensive Size Options

We manufacture spiral welded steel pipes with diameters ranging from 219mm to 3500mm and wall thicknesses from 6mm to 26mm.

International Standards

Our production adheres to API 5L, ASTM A53, ASTM A252, EN 10219, and other global standards.

Diverse Product Offerings

In addition to standard spiral pipes, we also provide: Coated spiral pipes, lined spiral pipes, pipe end protectors (bv protector), steel pipe cross bars, steel pipe clutches.

Core Data Of WUZHOU

CangLuo Group has 3 companies, 2 existing factories, 6 production plants, 4 production bases, covering an area of 350,000 square meters, 680+ employees, 11 steel pipe production lines, 2 coating lining production lines, and an annual output value of 400,000 tons of spiral welded pipes. The company ensures production capacity while producing spiral pipes of multiple specifications.

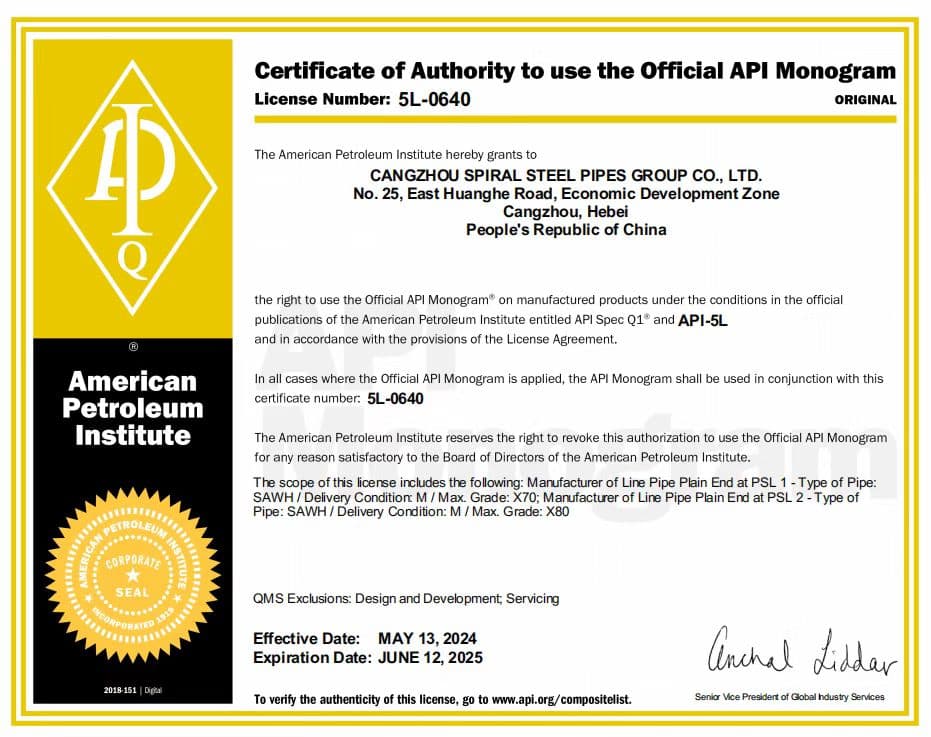

Certified Excellence, Trusted Manufacturer

We uphold the highest industry standards with internationally recognized certifications. Our double-sided submerged arc welded spiral steel pipes have passed the API 5L standard of the American Petroleum Institute and the EU standard. We also have ISO 9001、 ISO 14001 quality management systems and Environmental Management System Certification.

Quality control at every step of the process

We provide raw material report and quality inspection report for spiral welded steel pipes. Every spiral steel pipe produced by our factory is strictly quality controlled.(water pressure test, ultrasonic test and X-ray test). From the selection of raw materials to the completion of production, we ensure the quality of each spiral welded pipe.

Raw Material Testing

At the heart of our commitment to quality, all steel coils used in the production of our spiral steel pipes undergo rigorous physical and chemical testing.

Hydrostatic Pressure Testing

To guarantee the strength and leak-proof capability of our pipes, each spiral steel pipe is subjected to hydrostatic pressure testing.

Ultrasonic Inspection

To ensure the internal quality and structural integrity of our pipes, we conduct ultrasonic testing.

X-ray Inspection

Our X-ray inspection process focuses on detecting any hidden defects, particularly in the weld seams of our pipes.

Rapid response and timely delivery

Hebei Province ranks first in steel production in China, and steel is the primary raw material for manufacturing spiral welded steel pipes. Located in the plains of Hebei Province, Cangzhou City offers the ideal conditions for spiral pipe production.

Cangzhou is also a coastal city with convenient transportation links. It takes only 1 hour by high-speed train to travel from Cangzhou to Beijing, the capital of China. Additionally, it takes just 2 hours to transport steel pipes to Tianjin Port and over 1 hour to Huanghua Port, ensuring efficient delivery and logistics for both domestic and international shipments.