Quality Management

Raising the Bar in Steel Pipe Quality

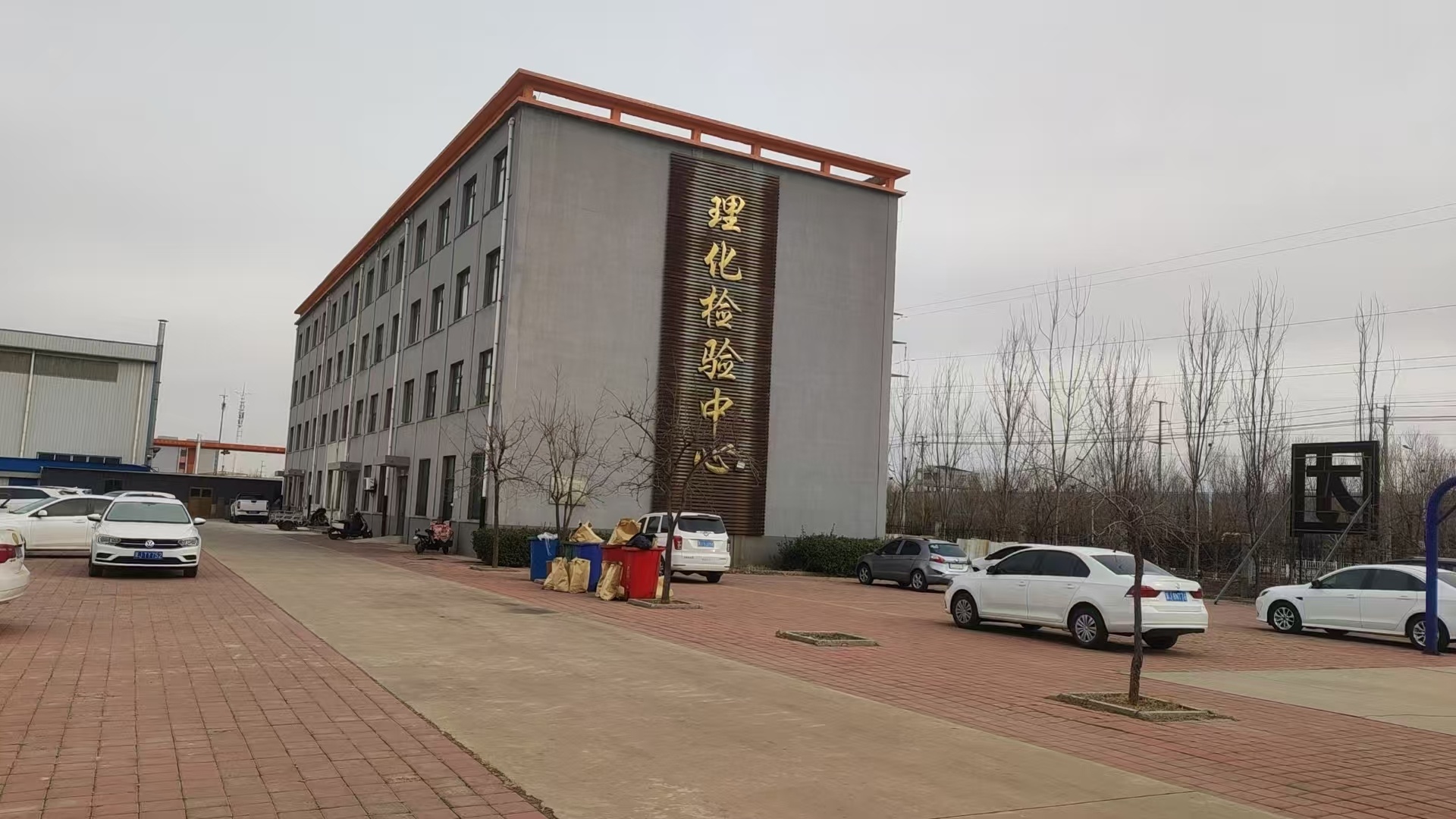

Raw Material Testing

At the heart of our commitment to quality, all steel coils used in the production of our spiral steel pipes undergo rigorous physical and chemical testing. These tests ensure the raw materials meet the highest industry standards for strength, durability, and resistance to corrosion. We work closely with certified suppliers and continuously monitor the quality of the raw materials to maintain consistency and reliability throughout the manufacturing process.

Our hydrostatic test machine is designed to ensure the leak-proof performance of our spiral steel pipes by testing their ability to withstand high-pressure conditions.

Hydrostatic Pressure Testing

To guarantee the strength and leak-proof capability of our pipes, each spiral steel pipe is subjected to hydrostatic pressure testing. This process simulates real-world conditions by pressurizing the pipe to detect any weaknesses or leaks. Our advanced testing equipment can test pipes at varying pressure levels, ensuring they are fit for use in demanding industries like oil, gas, and water transmission. This rigorous inspection ensures that all our pipes can withstand the pressures they will encounter in the field.

Ultrasonic Inspection

To ensure the internal quality and structural integrity of our pipes, we conduct ultrasonic testing, a non-destructive inspection method that detects any internal flaws such as cracks or voids. This testing method provides a high level of accuracy, ensuring that each pipe is free of defects that could compromise its performance. By utilizing state-of-the-art ultrasonic technology, we can ensure that only pipes with the highest level of quality are delivered to our customers.

Our X-ray Industrial TV Test provides detailed internal inspection of spiral steel pipes, ensuring flawless welds and structural integrity.

X-ray Inspection

Our X-ray inspection process focuses on detecting any hidden defects, particularly in the weld seams of our pipes. This advanced testing method is crucial in ensuring the quality and safety of the welded areas, which are critical to the overall strength of the pipe. By examining the internal structure of the pipe, X-ray inspection provides an accurate assessment of the weld quality, helping us maintain the highest standards in pipe manufacturing. This non-destructive testing method ensures that every pipe produced is free from defects and meets all regulatory requirements.