API 5L PSL1 Spiral Pipe: The Ultimate Guide for 2025

February 20, 2025

Share This Article

Introduction to API 5L PSL1 Spiral Pipe

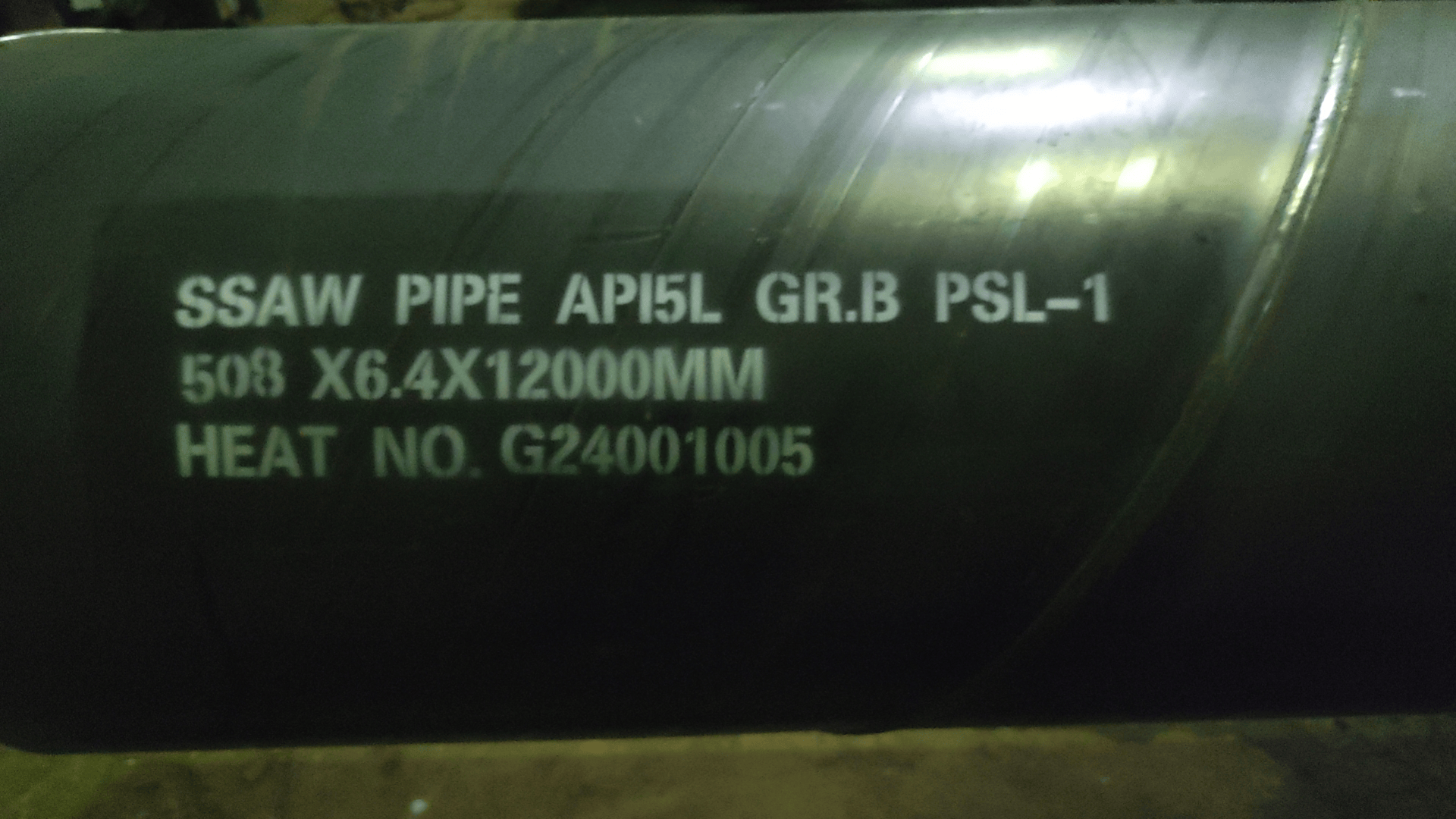

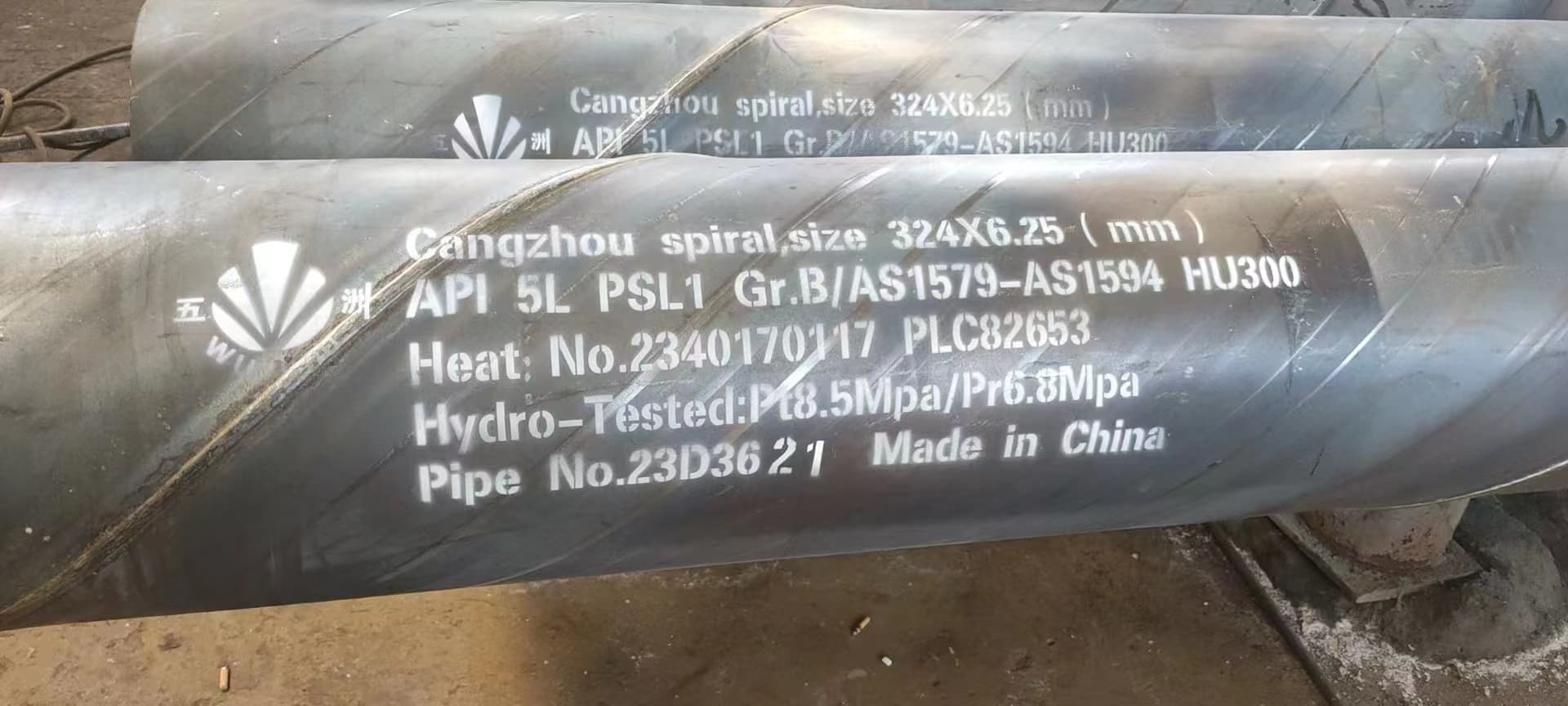

API 5L PSL1 spiral pipe is a high-strength, welded steel pipe used primarily in oil and gas pipelines, water transmission systems, and structural applications. Manufactured using spiral submerged arc welding (SSAW), these pipes provide excellent mechanical properties, durability, and cost-effectiveness.

API 5L PSL1 is the basic standard level of API 5L pipes, offering reliable performance for non-critical applications. It is widely used in low-pressure pipeline systems, structural support, and general industrial projects.

Why Choose API 5L PSL1 Spiral Pipe?

✔ Cost-effective option for large-diameter pipelines

✔ Complies with API 5L standards for oil, gas, and water pipelines

✔ Available in various steel grades (B, X42, X52, X60, etc.)

✔ Suitable for low to medium-pressure applications

✔ Easier manufacturing and lower cost compared to PSL2 pipes

This guide will cover API 5L PSL1 spiral pipe specifications, pricing, manufacturing process, key suppliers, and comparison with PSL2 pipes.

API 5L PSL1 Spiral Pipe Specifications & Standards

API 5L PSL1 spiral pipes must meet specific mechanical, chemical, and dimensional requirements to ensure quality and durability. Below are the key specifications:

Chemical Composition Requirements

| Steel Grade | C (Max%) | Mn (Max%) | P (Max%) | S (Max%) |

|---|---|---|---|---|

| Grade B | 0.26 | 1.2 | 0.030 | 0.030 |

| X42 | 0.26 | 1.3 | 0.030 | 0.030 |

| X52 | 0.26 | 1.4 | 0.030 | 0.030 |

| X60 | 0.26 | 1.4 | 0.030 | 0.030 |

Mechanical Properties

| Steel Grade | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|

| Grade B | 245 | 415 |

| X42 | 290 | 415 |

| X52 | 360 | 460 |

| X60 | 415 | 520 |

Dimensional Specifications

API 5L PSL1 spiral pipes are available in a wide range of diameters and wall thicknesses:

✔ Diameter Range: Φ219mm – Φ3500mm

✔ Wall Thickness: 6mm – 26mm

✔ Pipe Length: 6m, 9m, 12m, or customized

✔ End Finish: Plain end, bevelled end, threaded & coupled

Cangzhou Spiral Steel Pipes Group provides API 5L PSL1 spiral pipes with full compliance to global standards.

API 5L PSL1 Spiral Pipe vs. API 5L PSL2: Key Differences

API 5L PSL1 and PSL2 are two levels of pipeline steel quality. While PSL1 is the basic standard for general use, PSL2 offers higher quality and stricter requirements.

| Feature | API 5L PSL1 | API 5L PSL2 |

|---|---|---|

| Manufacturing Requirements | Basic | Strict |

| Chemical Composition Limits | Higher tolerance | Lower tolerance |

| Mechanical Properties | Standard strength | Higher strength |

| Impact Testing | Not required | Required for certain grades |

| Non-Destructive Testing (NDT) | Basic inspection | More rigorous testing |

| Best For | Low to medium-pressure pipelines | High-pressure, critical applications |

Which One Should You Choose?

✔ For standard oil, gas, and water pipelines → API 5L PSL1 is sufficient

✔ For high-pressure or offshore projects → API 5L PSL2 is recommended

Cangzhou Spiral Steel Pipes Group manufactures both PSL1 and PSL2 spiral pipes to meet diverse industry needs.

API 5L PSL1 Spiral Pipe Price Per Ton (2025)

The price of API 5L PSL1 spiral pipes depends on factors like steel grade, diameter, wall thickness, and coatings. Below is an estimated wholesale price per ton for 2025:

| Wall Thickness (mm) | Steel Grade | Price Per Ton (USD) |

|---|---|---|

| 6 – 10 mm | API 5L X42 – X52 | 600−600 – 600−900 |

| 12 – 18 mm | API 5L X52 – X60 | 850−850 – 850−1,200 |

| 20 – 26 mm | API 5L X60 – X70 | 1,100−1,100 – 1,100−1,500 |

Factors Affecting Pricing

✔ Steel Grade: Higher grades (like X60, X70) cost more.

✔ Customization: Coatings, special dimensions, and end finishes increase the price.

✔ Order Quantity: Bulk purchases lower costs per ton.

✔ Shipping Costs: Prices vary depending on destination and freight charges.

Cangzhou Spiral Steel Pipes Group offers competitive pricing for bulk API 5L PSL1 spiral pipe orders.

Best API 5L PSL1 Spiral Pipe Suppliers in China

1. Cangzhou Spiral Steel Pipes Group Co., Ltd (Best for Large-Scale Projects)

✔ 27+ years of experience in SSAW pipe manufacturing

✔ 13 production lines, 400,000 tons annual capacity

✔ Certified by API 5L, ASTM A252, GB/T9711, ISO 9001

✔ Custom coatings available: FBE, 3LPE, and 3LPP

📍 Location: No. 92, Jiefang East Road, Xinhua District, Cangzhou, China

📞 Contact: Request a Quote

2. Tianjin Youfa Steel Pipe Group (Best for Structural & Piling Applications)

✔ Specializes in piling pipes and structural SSAW pipes

✔ Strong international distribution network

📍 Location: Tianjin, China

📞 Contact: Request a Quote

3. Hengyang Valin Steel Tube Co., Ltd (Best for Oil & Gas Pipelines)

✔ Specializes in API 5L-certified SSAW pipes for energy projects

✔ Advanced non-destructive testing (NDT) and quality control

📍 Location: Hengyang, China

📞 Contact: Request a Quote

Cangzhou Spiral Steel Pipes Group is a trusted supplier of API 5L PSL1 spiral pipes, offering global shipping and competitive pricing.

API 5L PSL1 Spiral Pipe Coating & Anti-Corrosion Protection

Why Is Coating Important for API 5L PSL1 Spiral Pipes?

API 5L PSL1 spiral pipes are primarily used in oil, gas, and water transmission pipelines, where they are exposed to harsh environments, moisture, and corrosive elements. Without proper coating, these pipes can rust, weaken, and fail over time, leading to significant maintenance costs and pipeline failures.

Common Coating Types for API 5L PSL1 Spiral Pipes

| Coating Type | Best For | Corrosion Resistance | Temperature Resistance | Advantages |

|---|---|---|---|---|

| Fusion Bonded Epoxy (FBE) | Oil & gas pipelines | High | Up to 85°C | Strong adhesion, chemical resistance, smooth surface |

| 3-Layer Polyethylene (3LPE) | Underground pipelines | Very High | Up to 85°C | Excellent corrosion protection, impact resistance |

| 3-Layer Polypropylene (3LPP) | Offshore pipelines | Very High | Up to 140°C | High impact resistance, superior mechanical strength |

| Coal Tar Epoxy (CTE) | Marine environments | Very High | Up to 100°C | Cost-effective, effective in high-moisture areas |

| Galvanized Coating | Structural applications | Moderate | Up to 60°C | Affordable, suitable for general-purpose use |

Choosing the Right Coating for Your Project

✔ For underground pipelines → 3LPE or 3LPP is best

✔ For offshore applications → 3LPP or Coal Tar Epoxy works well

✔ For industrial water pipelines → FBE provides excellent protection

Cangzhou Spiral Steel Pipes Group offers customized coating solutions to meet specific project requirements.

How to Import API 5L PSL1 Spiral Pipes from China?

Step-by-Step Guide to Importing API 5L PSL1 Spiral Pipes

✔ Step 1: Choose a Reliable Supplier

- Verify API 5L, ASTM, and ISO certifications

- Check production capacity and quality standards

- Request product samples and factory inspections

✔ Step 2: Request a Quotation

- Provide pipe specifications (diameter, thickness, steel grade, coating type)

- Get pricing for FOB, CIF, or EXW terms

✔ Step 3: Negotiate Terms & Finalize Order

- Discuss payment terms (T/T, L/C, etc.)

- Confirm production lead time and delivery schedule

✔ Step 4: Quality Inspection & Testing

- Arrange for third-party inspection (SGS, BV, etc.)

- Ensure compliance with contract specifications

✔ Step 5: Shipping & Customs Clearance

- Work with freight forwarders for smooth logistics

- Submit necessary customs documents (Bill of Lading, Packing List, Commercial Invoice, etc.)

Cangzhou Spiral Steel Pipes Group provides hassle-free export services, ensuring timely delivery worldwide.

Global Market Demand for API 5L PSL1 Spiral Pipes

Why Are API 5L PSL1 Spiral Pipes in High Demand?

✔ Growing Oil & Gas Infrastructure – Demand for reliable pipelines for crude oil, natural gas, and petroleum transport is increasing.

✔ Water Transmission Projects – Governments are investing in large-scale water pipelines for municipal supply and irrigation.

✔ Industrial Growth – Steel pipelines are widely used in power plants, refineries, and chemical industries.

✔ Structural & Piling Applications – SSAW pipes provide cost-effective solutions for bridges, buildings, and marine foundations.

Top Importing Regions for API 5L PSL1 Spiral Pipes

| Region | Key Applications | Demand (%) |

|---|---|---|

| North America (USA, Canada) | Oil & gas pipelines, water transmission | 30% |

| Europe (Germany, UK, France) | Industrial piping, offshore projects | 20% |

| Middle East (UAE, Saudi Arabia) | Oil pipelines, desalination plants | 25% |

| Southeast Asia (India, Indonesia) | Infrastructure, water supply | 15% |

| Africa & Latin America | Mining, energy, construction | 10% |

Cangzhou Spiral Steel Pipes Group exports high-quality API 5L PSL1 spiral pipes to over 50 countries worldwide.

Frequently Asked Questions (FAQ) About API 5L PSL1 Spiral Pipes

| Question | Answer |

|---|---|

| What is API 5L PSL1 spiral pipe used for? | Oil & gas pipelines, water transmission, piling, and structural applications. |

| What is the difference between PSL1 and PSL2? | PSL1 is for general use, while PSL2 has stricter quality requirements. |

| Can API 5L PSL1 pipes be custom-coated? | Yes, available coatings include 3LPE, 3LPP, FBE, and Coal Tar Epoxy. |

| What is the minimum order quantity (MOQ) for API 5L PSL1 pipes? | MOQ depends on the supplier, but bulk orders (50+ tons) receive better pricing. |

| How long does it take to manufacture API 5L PSL1 pipes? | Typically 15-45 days, depending on order size and specifications. |

| What are the payment terms for importing API 5L PSL1 pipes? | T/T (Telegraphic Transfer), L/C (Letter of Credit), and D/P (Documents Against Payment) are commonly used. |

| What sizes are available for API 5L PSL1 spiral pipes? | Diameters from Φ219mm to Φ3500mm, thicknesses from 6mm to 26mm. |

| Do API 5L PSL1 pipes require third-party inspection? | Not mandatory, but recommended for international buyers. |

| Can Cangzhou Spiral Steel Pipes Group export to my country? | Yes, we export to over 50 countries worldwide. |

Final Thoughts: Why Choose Cangzhou Spiral Steel Pipes Group for API 5L PSL1 Spiral Pipes?

For high-quality API 5L PSL1 spiral pipes, Cangzhou Spiral Steel Pipes Group Co., Ltd is your trusted supplier in 2025!

✔ 27+ years of experience in SSAW pipe manufacturing

✔ 400,000 tons annual production capacity

✔ Certified by API 5L, ASTM, GB/T, ISO 9001

✔ Custom sizes, coatings, and global shipping

✔ Competitive pricing for bulk orders

📞 Need a bulk quote or technical consultation? Contact Cangzhou Spiral Steel Pipes Group today!