Epoxy Resin Lined Pipe

Stock Availability Large inventory ready for immediate shipment.

Quality Assurance

Every pipe undergoes strict testing, including ultrasonic inspection, hydrostatic testing, and industrial TV inspection, ensuring compliance with API 5L and EU certifications.

OEM & ODM Service

We offer fully customizable solutions, from material selection to specialized coatings and dimensions, meeting diverse industry needs.

Ontime Delivery

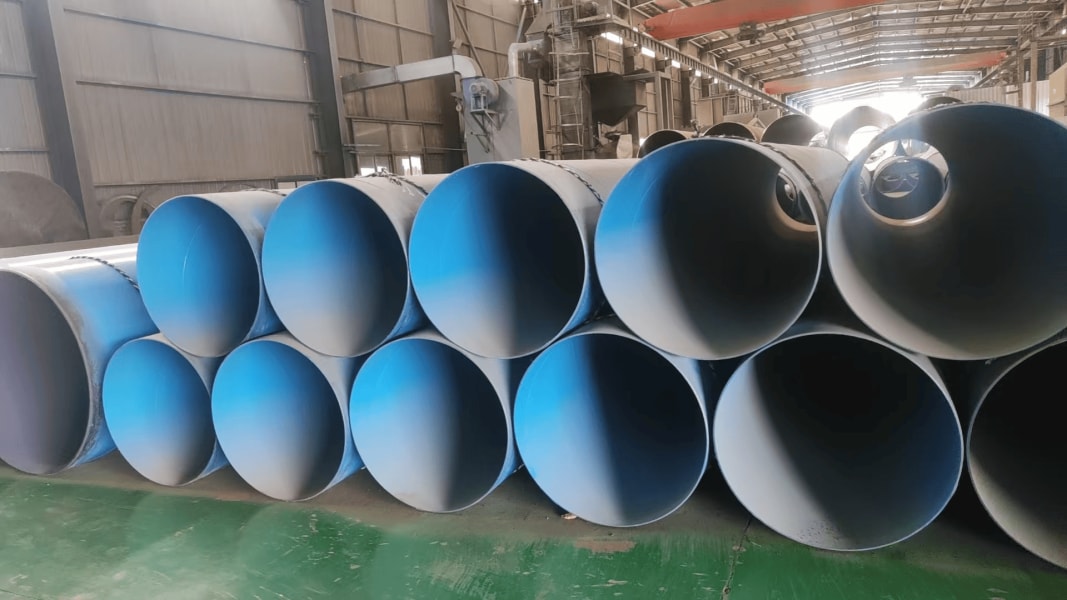

With 13 production lines, 4 anti-corrosion lines, and multiple manufacturing bases, we guarantee efficient production and timely delivery to global markets.

Share This Product

One-Stop Solution

From design to production, we provide customized spiral steel pipe solutions, including anti-corrosion coatings and quality assurance.

Wide Size Range

Our pipes range from Φ219mm to Φ3500mm, with varied wall thickness options, catering to diverse project requirements.

International Standards

Certified to API 5L, SY/T, and GB/T standards, our products meet global industry regulations for reliability and durability.

Overview of Epoxy Resin Lined Pipe

Epoxy Resin Lined Pipe is a high-performance anti-corrosion pipe widely used in water transmission, oil & gas pipelines, sewage systems, and industrial applications. The epoxy resin lining forms a protective barrier inside the pipe, preventing corrosion, contamination, and scale buildup.

Epoxy coatings have excellent adhesion to steel surfaces, making them ideal for potable water systems, wastewater treatment facilities, and chemical transport pipelines.

Key Features of Epoxy Resin Lined Pipe

✔ Superior corrosion resistance in water, oil, and chemical environments

✔ Smooth internal surface reduces friction and improves flow efficiency

✔ Non-toxic and safe for drinking water applications

✔ Strong adhesion to steel surfaces prevents coating peeling

✔ Resistant to high temperatures, chemicals, and abrasion

In this guide, we’ll explore Epoxy Resin Lined Pipes, including manufacturers, specifications, applications, price trends, and anti-corrosion benefits.

Top Epoxy Resin Lined Pipe Manufacturers

Choosing a trusted manufacturer ensures high-quality materials, compliance with coating standards, and long-lasting pipeline performance. Below are some of the leading Epoxy Resin Lined Pipe manufacturers in 2025:

1. Cangzhou Spiral Steel Pipes Group Co., Ltd

✔ 27 years of experience in steel pipe manufacturing

✔ 13 production lines for Φ219–Φ3500mm spiral welded pipes

✔ Epoxy resin, FBE, 3LPE, and IPN8710 coating solutions

✔ Annual production capacity: 400,000 tons

✔ ISO 9001, API 5L, and ASTM-certified coatings

2. Baosteel Group (China)

A top steel producer specializing in high-quality epoxy-coated pipes for water transmission and industrial applications.

3. Jindal SAW Ltd (India)

A major supplier of epoxy resin-lined spiral steel pipes for municipal water supply and oil & gas transport.

4. Tenaris (Global)

A leading manufacturer of anti-corrosion coated pipes for oil & gas pipelines, industrial piping, and offshore applications.

5. Welspun Corp Ltd (India)

A global leader in coated steel pipes, offering epoxy resin lining solutions for water transmission and wastewater management.

Each of these manufacturers ensures strict compliance with international coating standards, guaranteeing high durability and performance.

Epoxy Resin Lined Pipe vs Other Coated Pipes

Selecting the right coating system depends on application, durability, cost, and environmental factors. Here’s how Epoxy Resin Lined Pipe compares with other coating types:

| Feature | Epoxy Resin Lined Pipe | FBE (Fusion Bonded Epoxy) Coated Pipe | 3LPE (Three-Layer Polyethylene) Coated Pipe | Cement Mortar Lined Pipe |

|---|---|---|---|---|

| Corrosion Resistance | High | High | Very High | Moderate |

| Chemical Resistance | Excellent | High | Excellent | Low |

| Adhesion to Steel | Strong | Strong | Very Strong | Moderate |

| Friction Reduction | High | High | Moderate | Low |

| Suitability for Drinking Water | Yes | No | No | Yes |

| Best Use Case | Water pipelines, industrial piping | Oil & gas pipelines, marine applications | Underground pipelines, high-impact areas | Municipal water transmission |

Why Choose Epoxy Resin Lined Pipes?

✔ Ideal for water transmission due to non-toxic properties

✔ Stronger adhesion to steel surfaces than cement mortar lining

✔ Superior chemical resistance compared to FBE and 3LPE coatings

✔ Cost-effective solution for municipal and industrial pipelines

Epoxy Resin Lined Pipe Price Per Ton in 2025

The price of Epoxy Resin Lined Pipes varies based on factors such as pipe diameter, wall thickness, coating thickness, and raw material costs. Below is an estimated pricing chart for 2025:

| Pipe Diameter (mm) | Wall Thickness (mm) | Coating Thickness (μm) | Price Per Ton (USD) |

|---|---|---|---|

| 219 – 600 | 6 – 10 | 300 – 500 | 1,200−1,200 – 1,200−1,800 |

| 610 – 1200 | 8 – 14 | 400 – 600 | 1,500−1,500 – 1,500−2,200 |

| 1220 – 1800 | 10 – 18 | 500 – 800 | 1,800−1,800 – 1,800−2,600 |

| 2000 – 3500 | 12 – 25 | 600 – 1000 | 2,300−2,300 – 2,300−3,200 |

Factors Affecting Price:

✔ Coating Thickness – Thicker coatings cost more due to additional material usage.

✔ Pipe Diameter & Length – Larger pipes require more coating material, increasing costs.

✔ Manufacturing Costs – Labor, energy, and transportation expenses impact pricing.

✔ Bulk Orders – Large quantity orders receive better pricing.

Cangzhou Spiral Steel Pipes Group offers high-quality Epoxy Resin Lined Pipes at competitive prices.

Epoxy Resin Lined Pipe Manufacturing Process & Quality Control

How Is Epoxy Resin Lined Pipe Manufactured?

The epoxy resin lining process involves multiple steps of surface preparation, coating application, and curing to ensure strong adhesion and long-lasting protection. Below is a step-by-step breakdown of the epoxy resin lining process:

1. Surface Preparation

- The steel pipe undergoes shot blasting or sandblasting to remove rust, scale, and contaminants.

- The surface is cleaned and roughened to enhance adhesion of the epoxy coating.

2. Application of Epoxy Primer Layer

- The first layer consists of a specially formulated epoxy primer that penetrates the steel surface and provides strong adhesion.

- This primer is applied using airless spray techniques to ensure uniform coverage.

3. Application of Epoxy Topcoat

- The second layer is a high-performance epoxy resin coating that provides superior corrosion resistance.

- It is applied in multiple layers, depending on the required thickness and project specifications.

4. Curing & Drying

- The coated pipes are cured in a controlled environment to ensure proper hardening and chemical bonding.

- This step guarantees that the coating maintains its durability, flexibility, and resistance to cracking.

5. Quality Control & Testing

- Coating Thickness Measurement ensures the required film thickness is achieved.

- Adhesion Testing verifies the bond strength between the coating and steel surface.

- Hydrostatic & Pressure Testing assesses internal pressure resistance.

- Impact Resistance Testing ensures the coating can withstand mechanical stress.

6. Final Inspection & Packaging

- Pipes are visually inspected for defects and imperfections.

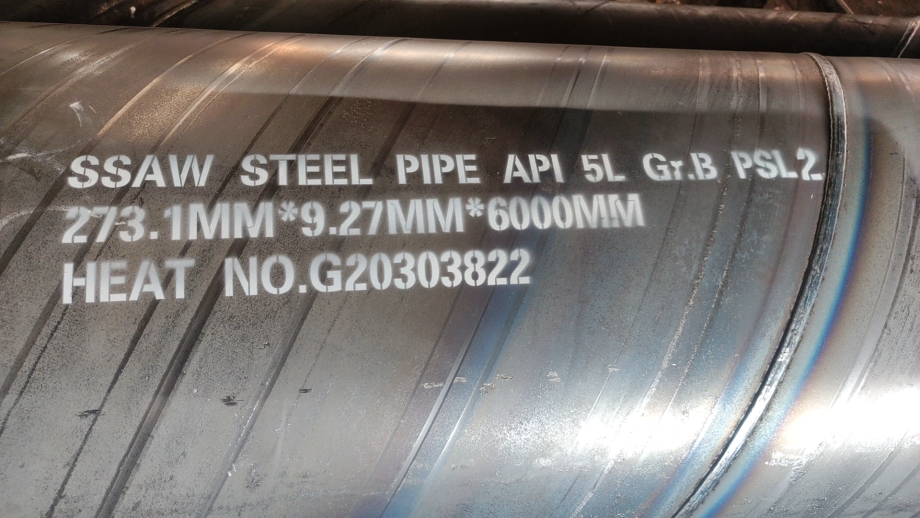

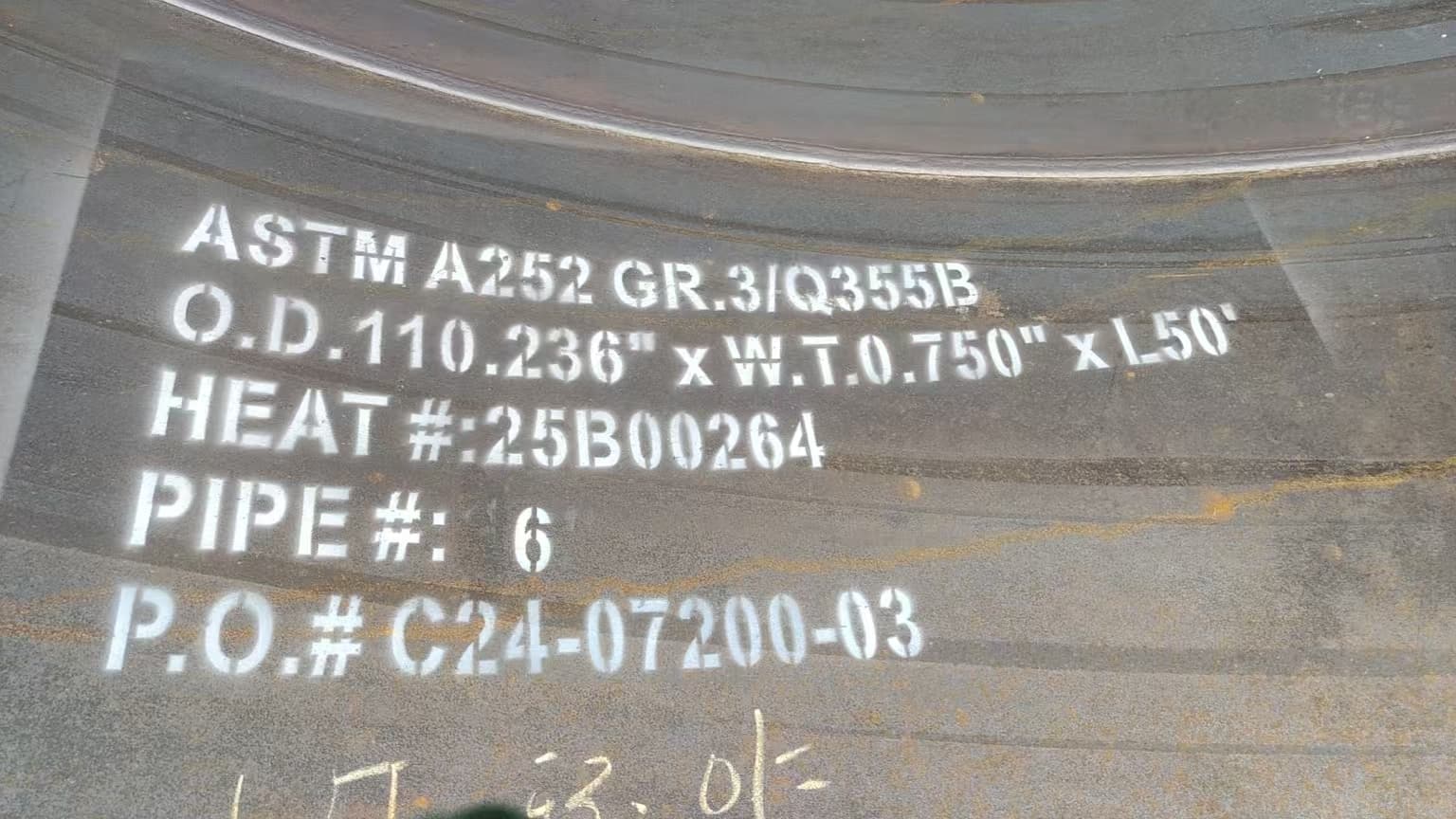

- They are marked with batch numbers, coating specifications, and manufacturer details for full traceability.

- Pipes are then bundled, packed, and prepared for shipping.

Why Epoxy Resin Lined Pipes Are Preferred?

✔ Strong adhesion ensures long-lasting protection

✔ Non-toxic and environmentally safe for potable water applications

✔ Smooth internal coating improves fluid flow and reduces energy consumption

✔ High resistance to chemicals, rust, and corrosion

Cangzhou Spiral Steel Pipes Group Co., Ltd ensures strict compliance with ISO, API, and industry standards for high-quality epoxy resin lined pipes.

Epoxy Resin Lined Pipe Applications & Industry Uses

Where Are Epoxy Resin Lined Pipes Used?

Epoxy Resin Lined Pipes are widely used in various industries where corrosion resistance, high durability, and smooth fluid transport are essential.

| Industry | Application | Why Epoxy Resin Lined Pipes? |

|---|---|---|

| Municipal Water Supply | Drinking water pipelines | Non-toxic, smooth inner lining prevents contamination |

| Oil & Gas Transmission | Low-pressure oil & gas transport | Corrosion-resistant, prevents internal scaling |

| Industrial Fluid Transport | Chemical & wastewater pipelines | High chemical resistance, long lifespan |

| Irrigation & Agriculture | Large-scale irrigation networks | Prevents rust, maintains water purity |

| Fire Protection Systems | Underground fire suppression pipelines | High durability, resistant to temperature variations |

Why Epoxy Resin Lining is Preferred for Water Transmission?

✔ Ensures safe and clean water transportation

✔ Prevents bacterial growth and internal scaling

✔ Reduces pipeline maintenance and operational costs

✔ Enhances pipeline lifespan in corrosive environments

Cangzhou Spiral Steel Pipes Group provides customized epoxy resin lined pipes for municipal, industrial, and agricultural applications.

Epoxy Resin Lined Pipe vs Other Anti-Corrosion Coatings

When selecting anti-corrosion coatings, it’s important to compare epoxy resin lining with other commonly used coatings.

| Feature | Epoxy Resin Lined Pipe | FBE (Fusion Bonded Epoxy) Coated Pipe | 3LPE (Three-Layer Polyethylene) Coated Pipe | Cement Mortar Lined Pipe |

|---|---|---|---|---|

| Corrosion Resistance | High | High | Very High | Moderate |

| Chemical Resistance | Excellent | High | Excellent | Low |

| Friction Reduction | High | High | Moderate | Low |

| Suitability for Drinking Water | Yes | No | No | Yes |

| Lifespan | 25-50 years | 20-40 years | 30-60 years | 20-30 years |

| Best Use Case | Water pipelines, industrial piping | Oil & gas pipelines, marine applications | Underground pipelines, high-impact areas | Municipal water transmission |

Key Advantages of Epoxy Resin Lined Pipes

✔ Smooth internal coating ensures efficient liquid flow

✔ Better adhesion and toughness compared to cement mortar lining

✔ Non-toxic, making it perfect for potable water applications

✔ More cost-effective for water transmission and industrial pipelines

Epoxy Resin Lined Pipe Suppliers & Exporters

If you are looking to import Epoxy Resin Lined Pipes, working with a reliable supplier ensures quality, competitive pricing, and timely delivery.

Top Chinese Exporters of Epoxy Resin Lined Pipes

| Company Name | Location | Annual Production Capacity |

|---|---|---|

| Cangzhou Spiral Steel Pipes Group Co., Ltd | Hebei, China | 400,000 tons |

| Baosteel Group | Shanghai, China | 500,000+ tons |

| Tianjin Steel Pipe Co. | Tianjin, China | 300,000 tons |

Why Choose Cangzhou Spiral Steel Pipes Group for Epoxy Resin Lined Pipes?

✔ 27 years of experience in steel pipe manufacturing

✔ ISO 9001, API 5L, and ASTM-certified coatings

✔ 13 production lines, covering diameters from 219mm to 3500mm

✔ Custom coatings and anti-corrosion treatments available

✔ Strong export network to North America, Europe, and Asia

For high-quality Epoxy Resin Lined Pipes, Cangzhou Spiral Steel Pipes Group Co., Ltd is a trusted supplier.

FAQ: Epoxy Resin Lined Pipe

| Question | Answer |

|---|---|

| What is Epoxy Resin Lined Pipe used for? | Used for water transmission, industrial piping, and corrosion-resistant applications. |

| How does Epoxy Resin compare to FBE coatings? | Epoxy resin is better for water pipelines, while FBE is preferred for oil & gas pipelines. |

| What is the lifespan of an Epoxy Resin Lined Pipe? | 25-50 years, depending on environmental exposure and maintenance. |

| Who is the best supplier? | Cangzhou Spiral Steel Pipes Group Co., Ltd is a leading supplier with ISO & API-certified coatings. |

| What is the price per ton in 2025? | Prices range from 1,200to1,200 to 1,200to3,200 per ton, depending on size and coating thickness. |

| Is Epoxy Resin coating safe for drinking water? | Yes, it is non-toxic and approved for potable water applications. |

| How are these pipes tested? | Coating adhesion, thickness measurement, and hydrostatic pressure tests ensure quality compliance. |

| Can Epoxy Resin Lined Pipes be used underground? | Yes, but additional external coatings like 3LPE are recommended for harsh soil conditions. |

Final Thoughts

Epoxy Resin Lined Pipes are widely used in water transmission, industrial piping, and corrosion-resistant applications due to their superior adhesion, smooth internal surface, and long lifespan.

For premium quality Epoxy Resin Lined Pipes, Cangzhou Spiral Steel Pipes Group Co., Ltd is your best choice in 2025!

Need a quote or more technical details? Contact Cangzhou Spiral Steel Pipes Group today!