La importancia de los tubos SSAW en el sector energético surcoreano

27 de marzo de 2025

Comparte este artículo

Introducción: Los tubos SSAW y su papel fundamental en las infraestructuras energéticas de Corea del Sur

En el panorama energético de Corea del Sur, en rápida evolución, los tubos soldados por arco sumergido en espiral (SSAW) se han convertido en la espina dorsal de proyectos de infraestructuras críticas. Corea del Sur es el décimo mayor consumidor de energía del mundo y un país que prácticamente carece de producción nacional de petróleo o gas natural, por lo que depende en gran medida de la importación de recursos energéticos.

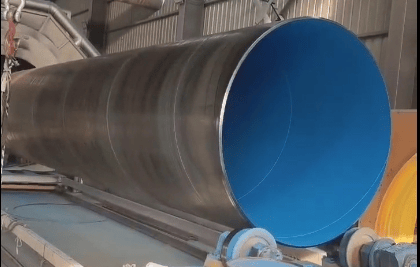

Los tubos SSAW, también conocidos como tubos soldados en espiral acero representan la cúspide de la tecnología moderna de tuberías para aplicaciones de gran diámetro y alta presión. Estas tuberías se fabrican mediante un avanzado proceso de soldadura por arco sumergido en espiral, en el que se forman y sueldan helicoidalmente tiras de acero para crear tuberías con una resistencia, integridad y rentabilidad superiores a las de los métodos tradicionales de fabricación de tuberías.

Por qué los tubos SSAW son importantes en las infraestructuras energéticas de Corea del Sur

Las infraestructuras energéticas de Corea del Sur se enfrentan a retos únicos que hacen que los tubos SSAW sean especialmente valiosos:

- Consideraciones geográficas: El terreno montañoso y los centros urbanos densamente poblados de Corea del Sur exigen sistemas de tuberías capaces de soportar condiciones geológicas variables sin perder fiabilidad operativa.

- Dependencia energética: Con más del 97% de los recursos energéticos importados, el transporte eficiente de petróleo, gas y agua a través de redes de oleoductos fiables es crucial para la seguridad energética nacional.

- Requisitos de seguridad estrictos: El marco normativo de Corea del Sur exige materiales de la máxima calidad para la transmisión de energía, con el fin de evitar riesgos medioambientales y garantizar la seguridad pública.

- Eficiencia económica: Para mantener unos precios competitivos de la energía en el mercado coreano es esencial contar con soluciones rentables y de alta calidad.

Principales ventajas de los tubos SSAW para los proyectos energéticos coreanos

| Beneficio | Descripción | Importancia para el mercado surcoreano |

|---|---|---|

| Mayor resistencia a la presión | Los tubos SSAW ofrecen una resistencia superior a las condiciones de alta presión | Fundamental para las líneas de transmisión de larga distancia que conectan las terminales costeras con las redes de distribución del interior |

| Eficiencia de costes | Más económicos que los tubos sin soldadura para aplicaciones de gran diámetro | Ayuda a gestionar los costes de infraestructura en el amplio sistema de importación de energía de Corea |

| Flexibilidad en la producción | Puede fabricarse en varias dimensiones con especificaciones precisas | Adaptable a los requisitos específicos de los proyectos energéticos coreanos |

| Calidad de soldadura superior | La soldadura por arco sumergido de doble cara garantiza la integridad estructural | Cumple las estrictas normas de seguridad de Corea para infraestructuras energéticas |

| Resistencia a la corrosión | Las avanzadas opciones de revestimiento protegen contra las variadas condiciones climáticas de Corea’ | Prolonga la vida útil en instalaciones costeras e interiores |

Para los proveedores mayoristas, distribuidores y gestores de proyectos energéticos de Corea del Sur, comprender el papel fundamental de los tubos SSAW es esencial para tomar decisiones de compra bien fundadas. El resto de este artículo profundizará en las especificaciones, aplicaciones y consideraciones de los proveedores específicamente relevantes para el sector energético de Corea del Sur.

Panorama energético de Corea del Sur: Tendencias actuales y evolución futura

Corea del Sur es un caso fascinante de desarrollo de infraestructuras energéticas. Como cuarto importador mundial de petróleo y segundo de GNL, el país ha construido sofisticadas redes de transporte de energía que dependen en gran medida de sistemas de gasoductos de alta calidad. Comprender este panorama es crucial para los proveedores mayoristas y los gestores de proyectos de gasoductos que deseen entrar o expandirse en el mercado coreano.

Panorama de la infraestructura energética actual

La infraestructura energética de Corea del Sur comprende:

- Redes de oleoductos: Abarca aproximadamente 1.200 kilómetros y conecta las terminales de importación con las refinerías y los centros de distribución

- Sistemas de transporte de gas natural: Más de 4.900 kilómetros de gasoductos de alta presión

- Redes regionales de distribución: Extensos sistemas municipales de tuberías que suministran energía a consumidores industriales y residenciales

- Líneas de transmisión transfronterizas: Corredores estratégicos de oleoductos que conectan las instalaciones costeras de importación con los centros energéticos del interior

La mayoría de estos sistemas críticos utilizan tubos de acero en espiral de gran diámetro, en los que predominan cada vez más los tubos SSAW por su rentabilidad y fiabilidad para diámetros superiores a 24 pulgadas.

Tamaño del mercado y previsiones de crecimiento

El mercado coreano de tubos SSAW para aplicaciones energéticas presenta importantes oportunidades para proveedores y distribuidores:

| Sector | Tamaño actual del mercado (2023) | Crecimiento anual previsto (2024-2028) | Principales impulsores |

|---|---|---|---|

| Transmisión de aceite | 420 millones de dólares | 4.2% | Ampliación de la refinería, desarrollo de instalaciones de almacenamiento |

| Gas natural | 680 millones de dólares | 6.8% | Construcción de terminales de GNL, cambio en la generación de electricidad |

| Integración del hidrógeno | 85 millones de dólares | 12.5% | Transición energética verde, iniciativas de economía del hidrógeno |

| Gestión del agua | 320 millones de dólares | 3.7% | Modernización de infraestructuras, adaptación al clima |

Estas cifras representan importantes oportunidades para los proveedores mayoristas de tubos SSAW de alta calidad, en particular para aquellos capaces de cumplir las especificaciones y los requisitos de certificación coreanos.

Evolución de las políticas que afectan a las infraestructuras de oleoductos y gasoductos

Varias iniciativas políticas clave en Corea del Sur están influyendo directamente en la demanda de tubos SSAW premium:

- Hoja de ruta hacia la neutralidad en carbono (2050): El compromiso de Corea del Sur con la neutralidad del carbono está acelerando la transición del carbón al gas natural, lo que exige nuevas infraestructuras de gasoductos.

- Plan de fomento de la economía del hidrógeno: La ambiciosa estrategia de hidrógeno del Gobierno requiere nuevos sistemas de tuberías preparados para el hidrógeno, con requisitos de material específicos que pueden cumplir los tubos SSAW de alta calidad.

- Programa de refuerzo de la seguridad energética: Tras las interrupciones de la cadena de suministro mundial, Corea está invirtiendo en la ampliación de las capacidades de almacenamiento y transmisión de reservas estratégicas de energía.

- Nuevo Pacto Verde: Las medidas de protección del medio ambiente exigen normas más estrictas para los materiales de las tuberías y las prácticas de instalación.

- Iniciativa Regional de Desarrollo Equilibrado: Los esfuerzos del Gobierno por distribuir la actividad industrial más allá de Seúl están creando demanda de nuevas infraestructuras de transmisión de energía en las zonas industriales emergentes.

Tendencias futuras de la demanda de tubos SSAW

Para los compradores mayoristas y los jefes de proyecto que evalúan estrategias de compra a largo plazo, varias tendencias emergentes determinarán las necesidades de tubos SSAW en Corea:

- Mezcla de hidrógeno: A medida que Corea apuesta por el hidrógeno como vector energético, las tuberías deben adaptarse a la mezcla de hidrógeno, lo que requiere propiedades metalúrgicas específicas.

- Digitalización: Los sistemas de tuberías inteligentes con capacidad de control integrada exigen tuberías fabricadas con tolerancias precisas y compatibles con las tecnologías de detección.

- Adaptación al clima: El aumento de los fenómenos meteorológicos extremos impulsa la demanda de materiales más resistentes para las tuberías.

- Construcción modular: Las metodologías de proyectos acelerados favorecen las secciones de tubería estandarizadas, listas para instalar y con una calidad constante.

- Asociaciones para la fabricación nacional: El impulso dado por Corea a la seguridad de la cadena de suministro está creando oportunidades para que los fabricantes internacionales de tuberías establezcan acuerdos de producción local o de asociación.

Para proveedores como WUZHOU, con capacidad para producir tubos de acero en espiral de alta especificación, estas tendencias representan importantes oportunidades de mercado en el sector energético coreano. La capacidad técnica para suministrar tubos que cumplan las normas coreanas con la certificación adecuada será un factor diferenciador clave para acceder a este valioso mercado.

Especificaciones técnicas y normas de calidad de los tubos SSAW en proyectos surcoreanos

Corea del Sur mantiene algunas de las normas técnicas más estrictas de Asia para los componentes de infraestructuras energéticas. Para los proveedores mayoristas y los promotores de proyectos, conocer estas especificaciones es esencial para entrar con éxito en el mercado y ejecutar los proyectos. En esta sección se detallan los requisitos técnicos fundamentales de los tubos SSAW en las aplicaciones energéticas coreanas.

Normas industriales coreanas para tubos SSAW

La Agencia Coreana de Tecnología y Normas (KATS) ha establecido requisitos específicos para los tubos SSAW utilizados en aplicaciones energéticas:

- KS D 3583: Normas para tubos soldados en espiral para usos estructurales generales

- KS D 3566: Especificaciones para tubos de acero al carbono para servicio a presión

- KS D 3570: Requisitos de los tubos de acero soldados de gran diámetro para servicio de alta presión

Además, los proyectos energéticos coreanos suelen exigir el cumplimiento de normas internacionales:

- API 5L: Especificaciones del Instituto Americano del Petróleo para tuberías

- ISO 3183: Normas internacionales para tuberías de acero destinadas a sistemas de transporte por tubería

- EN 10224: Normas europeas para tubos y accesorios de acero no aleado para agua y otros líquidos acuosos

Requisitos de calidad de los materiales para las aplicaciones energéticas coreanas

| Aplicación | Calidades de acero preferidas | Mínimo límite elástico | Dureza requerida |

|---|---|---|---|

| Transporte de gas natural | X60, X65, X70 | 415-485 MPa | CVN: 40J a -20°C |

| Sistemas de oleoductos | X52, X56, X60 | 360-415 MPa | CVN: 30J a -10°C |

| Agua a alta presión | L290, L320 | 290-320 MPa | CVN: 27J a 0°C |

| Sistemas preparados para el hidrógeno | Aleaciones especiales con base X65/X70 | 450-485 MPa | CVN: 40J a -30°C |

Los proyectos coreanos suelen especificar requisitos adicionales de resistencia al agrietamiento inducido por hidrógeno (HIC) y capacidad de servicio ácido en tuberías destinadas a determinadas aplicaciones.

Especificaciones dimensionales y de tolerancia

Los proyectos energéticos surcoreanos suelen especificar tubos SSAW con las siguientes características dimensionales:

- Diámetro: 508 mm (20″) a 2.540 mm (100″)

- Espesor de pared: de 6 mm a 25 mm para la mayoría de las aplicaciones

- Longitud: longitudes estándar de 12 m con opciones de personalización

Los requisitos críticos de tolerancia incluyen:

- Diámetro exterior±0,75% para tubos de hasta 48″ diámetro; ±0,5% para diámetros mayores

- Espesor de pared: -0,0/+12,5% para aplicaciones críticas

- Ovality: Máximo 1% del diámetro exterior especificado

- Escuadra final: Desviación máxima de 1,6 mm del cuadrado real

- Rectitud: Desviación máxima del 0,2% de la longitud del tubo

Requisitos de calidad e inspección de la soldadura

Los proyectos energéticos coreanos exigen un riguroso control de calidad de las soldaduras:

- Procedimientos de soldadura:

- La soldadura por arco sumergido de doble cara (DSAW) es estándar

- Control del aporte de calor para mantener las propiedades mecánicas

- Especificaciones de procedimiento de soldadura (WPS) cualificadas según ASME Sección IX o equivalente

- Ensayos no destructivos obligatorios:

- 100% de pruebas ultrasónicas de todas las soldaduras

- Pruebas radiográficas a intervalos especificados

- Prueba hidrostática a 1,5 veces la presión de diseño como mínimo

- Pruebas de dureza para aplicaciones de servicio de hidrógeno

- Requisitos de la documentación de calidad:

- Certificados de ensayo de materiales (EN 10204 3.1/3.2)

- Análisis de la composición química

- Informe de propiedades mecánicas

- Informes de inspección END con trazabilidad

Normas de revestimiento y protección contra la corrosión

Las condiciones climáticas y las normativas medioambientales coreanas exigen requisitos de revestimiento específicos:

| Tipo de revestimiento | Aplicaciones | Especificaciones |

|---|---|---|

| 3LPE (polietileno de tres capas) | Norma para tuberías enterradas | Fuerza de adherencia >8 N/mm², >7J/mm² resistencia al impacto |

| FBE (epoxi unido por fusión) | Aplicaciones de alta temperatura | 350-500μm de espesor, <5mV de disbondment catódico |

| Epoxi de alquitrán de hulla | Entornos marinos | 600-1000μm DFT, resistencia a la niebla salina >1000 horas |

| Revestimiento de mortero de cemento | Transmisión de agua | Conforme a AWWA C205, grosor de 9-19 mm |

Requisitos de certificación y garantía de calidad

Para suministrar tubos SSAW a los proyectos energéticos coreanos, los fabricantes deben mantener normalmente:

- ISO 9001 Certificación del sistema de gestión de la calidad

- ISO 14001 Certificación del Sistema de Gestión Medioambiental

- API 5L certificación para la fabricación de tuberías

- Certificación de productos de organismos de certificación coreanos reconocidos

- Aprobación de fábrica de empresas coreanas de ingeniería o clientes finales

Los fabricantes líderes como WUZHOU mantienen estas certificaciones y pueden proporcionar paquetes completos de documentación de calidad que cumplen los requisitos coreanos. Con 11 líneas dedicadas a la producción de tubos en espiral y 2 líneas especializadas de revestimiento y recubrimiento, WUZHOU garantiza el pleno cumplimiento de las estrictas normas exigidas por los proyectos energéticos surcoreanos.

Las modernas instalaciones de pruebas de WUZHOU, que incluyen pruebas hidrostáticas, inspección ultrasónica y pruebas de rayos X de cada tubo, proporcionan la documentación de garantía de calidad exigida por las empresas coreanas de ingeniería y los usuarios finales. Este compromiso con la calidad ha posicionado a WUZHOU como proveedor preferente de tubos SSAW de primera calidad para aplicaciones exigentes.

Para los compradores mayoristas y los promotores de proyectos que atienden al mercado coreano, estas especificaciones técnicas y normas de calidad representan requisitos innegociables. Asociarse con fabricantes experimentados como WUZHOU, que comprenden y cumplen sistemáticamente estas especificaciones, es esencial para la ejecución satisfactoria de proyectos en el sofisticado sector energético de Corea del Sur.

Aplicaciones clave de los tubos SSAW en el transporte de petróleo y gas en Corea del Sur

La posición de Corea del Sur como una de las principales economías de Asia ha hecho necesario el desarrollo de sofisticadas redes de transmisión de energía para apoyar su base industrial y sus centros urbanos. Los tubos SSAW desempeñan un papel fundamental en múltiples aplicaciones dentro de este ecosistema de infraestructuras vitales. Esta sección explora las aplicaciones específicas en las que los tubos soldados en espiral están teniendo un impacto más significativo en el sector energético de Corea del Sur.

Redes de transporte de gas natural

Corea del Sur ha ampliado agresivamente su infraestructura de gas natural como parte de su estrategia de transición energética, creando una demanda sustancial de tubos SSAW de gran diámetro.

Aplicaciones clave de los gasoductos de gas natural:

Tuberías de conexión de terminales de GNL: Las tuberías SSAW de gran diámetro (36″-64″) conectan las principales terminales de importación de GNL de Corea del Sur en Incheon, Pyeongtaek, Tongyeong y Samcheok con la red nacional de transporte.

Líneas troncales de alta presión: La Korean Gas Corporation (KOGAS) utiliza tubos SSAW para su red troncal de transporte de alta presión (75-80 bar), que requiere tubos de grado X65/X70 con espesores de pared de 12-22 mm.

Redes regionales de distribución: Los sistemas de media presión (40-45 bares) que suministran gas a zonas industriales y centrales eléctricas suelen utilizar tuberías SSAW de 24″-36″.

Corredores de transmisión entre países: Los principales corredores energéticos norte-sur y este-oeste emplean tubos SSAW por su rentabilidad en aplicaciones de larga distancia y gran diámetro.

Tipo de proyecto Especificaciones típicas Requisitos clave Proyectos recientes notables

Conexiones de terminal de GNL 48″-64″ diámetro, grado X70 Resistencia criogénica, clasificación de alta presión Ampliación del gasoducto de GNL de Boryeong (2022)

Red nacional de transmisión 36″-42″ diámetro, grado X65/X70 Alta tenacidad, resistencia a la fatiga Línea KOGAS Pyeongtaek-Chungju (2021)

Distribución en la zona industrial Diámetro de 24″-36″, grado X60/X65 Resistencia a la corrosión, facilidad de instalación Línea de suministro del complejo industrial de Daegu (2023)

Corredores transversales 30″-48″ diámetro, grado X65 Durabilidad a largo plazo, calidad constante Proyecto del corredor energético Este-Oeste (2020-2022)

Infraestructura de transporte de petróleo

A pesar de la transición energética mundial, los productos petrolíferos siguen siendo esenciales para la economía surcoreana, y los tubos SSAW desempeñan funciones críticas en este sector:

Aplicaciones de infraestructuras petrolíferas primarias:

Sistemas de interconexión de refinerías: Las tuberías SSAW conectan las principales refinerías de Corea del Sur (SK Energy, GS Caltex, S-Oil y Hyundai Oilbank) con las instalaciones portuarias y la red nacional de distribución.

Tuberías de la Reserva Estratégica de Petróleo: Las tuberías SSAW de gran diámetro conectan las terminales de importación con las instalaciones de almacenamiento estratégico en expansión de Corea, diseñadas para la seguridad energética.

Redes de distribución de productos: Los oleoductos de productos refinados que utilizan tecnología SSAW distribuyen gasolina, gasóleo y combustible para aviones a terminales regionales.

Sistemas marinos de carga y descarga: Los tubos SSAW especializados con protección anticorrosión mejorada se utilizan en las instalaciones de transferencia costera de Corea.

La reciente ampliación de la red de distribución de petróleo del Complejo Industrial Ulsan-Onsan ejemplifica la continua relevancia de los tubos SSAW en el sector petrolífero coreano, con aproximadamente 42 kilómetros de tubos soldados en espiral 36″ X60 instalados en 2022-2023.

Infraestructura emergente de la economía del hidrógeno

La ambiciosa Hoja de Ruta de la Economía del Hidrógeno de Corea del Sur ha creado nuevas oportunidades para las aplicaciones avanzadas de tuberías SSAW:

Desarrollo de la infraestructura del hidrógeno:

Gasoductos de gas natural preparados para el hidrógeno: Las nuevas tuberías de transporte de gas se están especificando para futuras mezclas de hidrógeno (hasta el 20%), lo que requiere una metalurgia y unos procedimientos de soldadura especializados.

Transmisión dedicada de hidrógeno: Los proyectos piloto para la transmisión de hidrógeno al 100% utilizan tuberías SSAW especialmente modificadas con revestimientos internos mejorados y calidades de acero especializadas.

Conexiones de instalaciones de producción de hidrógeno: Las tuberías SSAW conectan las instalaciones verdes y azules de producción de hidrógeno con la infraestructura de almacenamiento y distribución.

El Proyecto de Demostración de Hidrógeno de Changwon representa una implantación pionera de tuberías SSAW preparadas para el hidrógeno, con especificaciones de materiales que abordan los problemas de fragilización por hidrógeno mediante la modificación de la composición química del acero y la mejora del control de calidad.

Sistemas de gestión del agua al servicio de la producción de energía

En Corea del Sur, las infraestructuras hídricas están inextricablemente ligadas a la producción de energía, y los tubos SSAW tienen una doble función:

Sistemas de agua de refrigeración para centrales eléctricas: Las tuberías SSAW de gran diámetro con revestimientos especiales gestionan el agua de refrigeración de las centrales térmicas y nucleares de Corea.

Conexiones de plantas desalinizadoras: A medida que Corea amplía la capacidad de desalinización para cubrir las necesidades de agua de la industria, las tuberías de SSAW proporcionan las conexiones de gran diámetro necesarias.

Sistemas de recuperación de aguas residuales: Los sistemas de recuperación de aguas residuales industriales en complejos industriales energéticos emplean tuberías SSAW resistentes a la corrosión.

Sistemas hidroeléctricos de almacenamiento por bombeo: Las aplicaciones de tuberías forzadas de gran diámetro utilizan tuberías SSAW de alta presión para el almacenamiento de energía renovable.

Factores críticos del éxito de las aplicaciones de tubos SSAW en Corea

Para los proveedores mayoristas y los promotores de proyectos, varios factores determinan el éxito de los proyectos coreanos de infraestructuras energéticas:

Certificaciones y garantía de calidad: Documentación que demuestre el cumplimiento de las normas coreanas e internacionales

Asistencia técnica local: Capacidad para proporcionar consultas de ingeniería durante las fases de especificación e instalación

Entrega justo a tiempo: Capacidades logísticas para cumplir los ajustados plazos de los proyectos en el vertiginoso entorno de la construcción coreano

Capacidad de personalización: Flexibilidad para producir tuberías con requisitos específicos del proyecto

Asistencia posventa: Capacidad para resolver dudas técnicas durante la instalación y el funcionamiento

WUZHOU se ha consolidado como líder del mercado coreano de tubos SSAW destacando en estas áreas. Con 13 avanzadas líneas de producción, 11 dedicadas a tubos de acero en espiral y 2 de revestimiento, WUZHOU garantiza tanto la capacidad de producción como la calidad de los exigentes proyectos coreanos. El exhaustivo régimen de pruebas de la empresa, que incluye pruebas hidrostáticas, inspección ultrasónica y examen por rayos X de cada tubo, se ajusta perfectamente a las rigurosas expectativas de calidad de Corea.

Proveedores líderes de tubos SSAW para proyectos de infraestructuras energéticas en Corea del Sur

El mercado surcoreano de infraestructuras energéticas exige proveedores capaces de cumplir normas exigentes, cumplir los plazos de entrega y ofrecer precios competitivos. Esta sección examina el panorama de los proveedores de tubos SSAW que prestan servicio a proyectos coreanos y los factores que diferencian a los líderes del mercado.

Estructura actual del mercado de suministro de tubos SSAW a Corea

El mercado surcoreano de tubos SSAW para aplicaciones energéticas presenta una mezcla de proveedores internacionales y fabricantes nacionales:

Categoría de proveedores Cuota de mercado Posicionamiento competitivo Características destacadas

Proveedores internacionales de primer nivel 45% Calidad superior, certificaciones completas Asistencia técnica completa, calificaciones más altas, documentación completa

Fabricantes coreanos nacionales 30% Presencia local, relaciones con el gobierno Servicio receptivo, comprensión de los requisitos locales

Proveedores internacionales de nivel 2 25% Competitividad de costes, aplicaciones especializadas Niveles de calidad variables, asistencia técnica limitada

WUZHOU se ha establecido firmemente en la categoría Tier 1 a través de una calidad constante, certificaciones integrales, incluyendo API 5L y las normas ISO, y el apoyo técnico dedicado a los clientes coreanos. Como marca insignia de Cangzhou Spiral Steel Pipes Group, el reconocimiento de WUZHOU como una de las 10 mejores marcas chinas de tuberías de acero ha calado hondo entre los equipos de compras coreanos preocupados por la calidad.

Criterios clave de selección de proveedores de tubos SSAW para proyectos coreanos

Las empresas coreanas de ingeniería y las compañías energéticas evalúan a los proveedores de tubos SSAW en función de varios factores críticos:

- Capacidad técnica y garantía de calidad

Los compradores coreanos dan prioridad a los proveedores con:

Experiencia demostrada con tubos de gran diámetro de grado X60-X70

Capacidades avanzadas de END y protocolos de inspección al 100

Documentación de calidad rastreable y certificaciones de materiales

Control dimensional y calidad de soldadura constantes

La inversión de WUZHOU’ en tecnología de producción de vanguardia y sistemas de control de calidad exhaustivos -incluidas pruebas de presión de agua, pruebas ultrasónicas e inspección por rayos X de cada tubo- responde directamente a estos requisitos, estableciendo a la empresa como un proveedor de confianza para los proyectos energéticos coreanos más importantes.

- Capacidad de producción y fiabilidad de las entregas

Los proyectos energéticos coreanos típicos requieren:

Capacidad para grandes volúmenes (a menudo más de 10.000 toneladas por proyecto)

Programación precisa de las entregas para una construcción eficiente

Fabricación flexible para adaptarse a los ajustes de las especificaciones

Coordinación logística fiable para envíos al extranjero

Con una capacidad de producción anual de 400.000 toneladas repartidas en 11 líneas de producción de tubos en espiral y 4 bases de producción, WUZHOU ofrece la escala y la flexibilidad que requieren los grandes proyectos de infraestructuras coreanos. Esta capacidad garantiza la entrega a tiempo incluso de los pedidos más grandes, un factor crítico en el acelerado entorno de construcción coreano.

- Asistencia técnica y capacidad de servicio

Los proyectos coreanos cada vez tienen más valor:

Asesoramiento técnico previo al proyecto sobre la selección de materiales

Asistencia técnica sobre el terreno durante la instalación

Respuesta rápida a las consultas técnicas

Documentación de apoyo para el cumplimiento de la normativa

WUZHOU ha desarrollado capacidades de asistencia técnica específicas para el mercado coreano, incluidos paquetes de documentación especializados que cumplen los requisitos normativos coreanos y capacidades de asistencia sobre el terreno.

- Certificación y conformidad

Las cualificaciones obligatorias de los proveedores incluyen:

Certificación API 5L para la fabricación de tuberías

Sistemas de gestión de la calidad ISO 9001

Sistemas de gestión medioambiental ISO 14001

Aprobaciones y referencias de clientes coreanos

La amplia cartera de certificaciones de WUZHOU’, que incluye la certificación API 5L y los sistemas de gestión ISO 9001/14001, posiciona a la empresa como un proveedor plenamente cualificado para las infraestructuras energéticas coreanas. Los tubos de acero en espiral de la empresa han superado las normas API 5L y de la UE, y cumplen los criterios de calidad internacionales que exigen los proyectos coreanos.

Casos prácticos de proveedores en la infraestructura energética coreana

Varios proyectos coreanos recientes de infraestructuras energéticas ilustran el éxito de las asociaciones de suministro de tubos SSAW:

Caso 1: Expansión del transporte de gas en la provincia de Gyeonggi

Requisitos del proyecto: tubos SSAW 42″ X65 con mayor tenacidad para zonas sísmicas

Desafíos: Plazos de entrega ajustados, documentación de calidad estricta

Solución para proveedores: Calendario de producción específico, programa de pruebas mejorado

Resultados: Finalización a tiempo con cero incidentes de calidad

Caso 2: Red de tuberías del complejo industrial de Ulsan

Requisitos del proyecto: tubos SSAW 36″ X60 con revestimiento especializado para zona industrial

Desafíos: Logística compleja, especificaciones técnicas variables

Solución para proveedores: Asesoramiento técnico, programa de entrega justo a tiempo

Resultados: Aplicación satisfactoria con ajustes mínimos del emplazamiento

Caso 3: Conexión de la terminal de GNL de la isla de Jeju

Requisitos del proyecto: tubos SSAW 48″ X70 para entorno marino

Desafíos: Protección contra la corrosión, requisitos especiales de manipulación

Solución del proveedor: Sistema de revestimiento mejorado, embalaje a medida para transporte marítimo

Resultados: Mayor resistencia a la corrosión en entornos difíciles

WUZHOU ha participado en proyectos coreanos similares de gran envergadura, demostrando sistemáticamente la combinación de calidad, asistencia técnica y fiabilidad de entrega que exigen las infraestructuras energéticas coreanas.

Futuras tendencias de la cadena de suministro en la adquisición de tubos SSAW coreanos

Varias tendencias emergentes están reconfigurando la adquisición de tubos SSAW para los proyectos energéticos coreanos:

Resistencia de la cadena de suministro: Los compradores coreanos están diversificando sus bases de proveedores al tiempo que establecen relaciones más profundas con socios de probada eficacia.

Colaboración técnica: Creciente énfasis en la participación temprana de los proveedores en la selección de materiales y el desarrollo de especificaciones.

Documentación sobre sostenibilidad: Aumento de los requisitos de datos de impacto ambiental, información sobre la huella de carbono y certificaciones de sostenibilidad.

Documentación digital: Movimiento hacia sistemas digitales de certificación de materiales y documentación de calidad.

Análisis del coste del ciclo de vida: Pasar del precio inicial al valor total del ciclo de vida, incluyendo la facilidad de instalación, los requisitos de mantenimiento y la vida útil.

WUZHOU está bien posicionada para hacer frente a estas tendencias, gracias a sus completos sistemas de gestión de la calidad, la transparencia de su documentación y su enfoque de colaboración en las relaciones con los clientes. La capacidad de la empresa para proporcionar informes detallados sobre los materiales y documentación de inspección de calidad está en consonancia con el movimiento de Corea hacia prácticas de adquisición más sofisticadas.

Por qué los tubos de acero en espiral de WUZHOU destacan en las aplicaciones energéticas de Corea del Sur

El exigente entorno de las infraestructuras energéticas de Corea del Sur requiere proveedores de tubos SSAW que puedan ofrecer una calidad, fiabilidad y valor excepcionales. WUZHOU ha surgido como un proveedor preferido en este mercado competitivo a través de una combinación de excelencia en la fabricación, garantía de calidad y servicio centrado en el cliente.

Excelencia en la fabricación: Producción a medida para una calidad superior

Las capacidades de fabricación de WUZHOU’ están diseñadas específicamente para satisfacer los exigentes requisitos de las infraestructuras energéticas críticas:

Tecnología de producción avanzada:

11 líneas específicas de producción de tubos en espiral que permiten un control preciso de las especificaciones

2 líneas de producción especializadas en revestimientos y recubrimientos para una protección completa de las superficies

Tecnología punta de conformado en espiral que garantiza la precisión dimensional

Proceso avanzado de soldadura por arco sumergido de doble cara para una integridad superior de la soldadura

Escala de producción y flexibilidad:

capacidad de producción anual de 400.000 toneladas que garantiza la disponibilidad para grandes proyectos

Múltiples bases de producción que proporcionan redundancia y fiabilidad de fabricación

Diversas capacidades de producción que abarcan diámetros de 219 mm a 3500 mm

Grosor de pared desde 5 mm hasta 25 mm, líder del mercado

Experiencia en materiales:

Selección de acero especializado para los requisitos de los proyectos coreanos

Experiencia en tubos de grado X60, X65 y X70, especificados habitualmente en aplicaciones energéticas coreanas

Capacidades en metalurgia especializada para aplicaciones preparadas para el hidrógeno

Procedimientos de soldadura optimizados para aplicaciones de alta resistencia en zonas sísmicas

Esta base de fabricación permite a WUZHOU producir sistemáticamente los tubos SSAW de altas especificaciones que requieren los proyectos energéticos coreanos, desde los gasoductos de transmisión de GNL hasta las infraestructuras de reservas estratégicas de petróleo.

Garantía de calidad integral conforme a las normas coreanas

El sistema de garantía de calidad de WUZHOU’ responde directamente a los estrictos requisitos de los proyectos coreanos de infraestructuras energéticas:

Control de calidad de principio a fin:

inspección del 100% de las materias primas antes de la producción

Control continuo durante el proceso de fabricación

Inspección final exhaustiva de cada tubo producido

Capacidades de ensayo avanzadas:

Pruebas de presión hidrostática para verificar la integridad estructural

Pruebas ultrasónicas para verificar la calidad de las soldaduras

Pruebas de rayos X para la inspección detallada de soldaduras

Pruebas de propiedades mecánicas para confirmar la resistencia y tenacidad del material

Documentación detallada:

Certificados de materias primas con análisis químicos completos

Registros del proceso de producción que garanticen la trazabilidad

Informes exhaustivos de inspección de calidad

Documentación de los resultados de las pruebas para el cumplimiento de la normativa

Tipo de prueba Norma WUZHOU Requisito coreano Beneficio para los proyectos coreanos

Pruebas hidrostáticas 100% de las tuberías 5% de muestra mínima Mayor fiabilidad, menos pruebas in situ

Inspección por ultrasonidos 100% de las soldaduras 10% de muestra mínima Verificación exhaustiva de la calidad, reducción del riesgo de rechazo

Pruebas de rayos X Zonas críticas en todas las tuberías Comprobación por puntos Aseguramiento superior de la calidad de las soldaduras, documentación de conformidad

Análisis químicos Informes completos Certificación estándar Proceso de aceptación simplificado, cumplimiento de la normativa

Este completo programa de garantía de calidad proporciona a los clientes coreanos confianza en los productos de WUZHOU, minimizando los riesgos del proyecto y garantizando el cumplimiento de la normativa.

Cartera de certificación internacional

Las credenciales de certificación de WUZHOU’ se ajustan perfectamente a los requisitos de los proyectos coreanos:

Certificación API 5L: Cumplimiento de las normas del Instituto Americano del Petróleo esenciales para los proyectos coreanos de petróleo y gas

Cumplimiento de las normas de la UE: Cumplimiento de los requisitos técnicos europeos a los que a menudo se hace referencia en las especificaciones coreanas

Certificación ISO 9001: Demostración de los sistemas de gestión de la calidad exigidos por los procesos de contratación coreanos

Certificación ISO 14001: La verificación de las prácticas de gestión medioambiental, cada vez más importante en los proyectos coreanos

Estas certificaciones, reconocidas internacionalmente, simplifican el proceso de cualificación para las empresas de ingeniería coreanas y los clientes finales, agilizando la contratación y la ejecución de los proyectos.

Servicio orientado al cliente para el mercado coreano

WUZHOU ha desarrollado capacidades especializadas para servir al mercado coreano de infraestructuras energéticas:

Consulta técnica:

Orientación para la selección de materiales previa al proyecto

Recomendaciones para optimizar las especificaciones

Asistencia en la selección de revestimientos

Asesoramiento técnico específico para cada aplicación

Optimización de la logística:

Programación coordinada de las entregas

Embalaje protegido para el transporte marítimo

Preparación de la documentación para la aduana coreana

Supervisión de la carga para evitar daños

Asistencia posventa:

Asistencia técnica sobre el terreno durante la instalación

Apoyo a la documentación de calidad para el cierre de proyectos

Respuesta a consultas técnicas durante el funcionamiento

Garantía a largo plazo

Este enfoque orientado al servicio ha consolidado a WUZHOU como algo más que un simple proveedor, sino como un valioso socio en el desarrollo de las infraestructuras energéticas coreanas.

Propuesta de valor coste-rendimiento

Para los proyectos coreanos en los que se equilibran los requisitos de calidad con las limitaciones presupuestarias, WUZHOU ofrece una propuesta de valor convincente:

Calidad superior a precios competitivos gracias a la eficacia de la fabricación

Reducción de los costes de instalación gracias a una precisión dimensional constante

Menores costes de inspección y ensayo gracias a una completa documentación de fábrica

Reducción al mínimo de los retrasos en los proyectos gracias a la fiabilidad de las entregas y la coherencia de la calidad

Mayor vida útil gracias a la calidad superior de los materiales y la fabricación

Esta combinación de calidad, servicio y valor ha convertido a WUZHOU en el proveedor preferido de las empresas de ingeniería y energéticas coreanas más exigentes, que buscan el equilibrio óptimo entre rendimiento y rentabilidad en aplicaciones de infraestructuras críticas.

Testimonios de clientes e historias de éxito de proyectos

El éxito de WUZHOU’ en el mercado coreano se refleja en las opiniones de los clientes y en los resultados de los proyectos:

“Los tubos de acero en espiral de WUZHOU’ cumplen sistemáticamente nuestras exigentes especificaciones para aplicaciones críticas de transmisión de gas. Su completa documentación de calidad y su puntualidad en las entregas les han convertido en un valioso socio en nuestro programa de desarrollo de infraestructuras” – Senior Procurement Manager, Korean Gas Corporation project

“Hemos especificado WUZHOU tuberías para nuestra reciente expansión de la zona industrial sobre la base de su historial probado de calidad y servicio. El apoyo técnico durante las fases de desarrollo de especificaciones e instalación contribuyó significativamente al éxito de nuestro proyecto

Estos testimonios reflejan el compromiso de WUZHOU’ con la excelencia en el servicio al mercado coreano de infraestructuras energéticas, estableciendo a la empresa como un socio de confianza para las aplicaciones más exigentes.

Análisis de costes y retorno de la inversión: Invertir en tubos SSAW de alta calidad para proyectos energéticos coreanos

En el sofisticado sector energético de Corea del Sur, las decisiones de compra se centran cada vez más en el coste total de propiedad y no sólo en el precio de compra inicial. Esta sección ofrece un análisis exhaustivo de las consideraciones económicas que rodean la selección de tubos SSAW para los proyectos coreanos de infraestructuras energéticas.

Análisis del coste inicial frente al valor de la vida útil

Al evaluar las tuberías SSAW para los proyectos energéticos coreanos, los equipos de compras deben equilibrar las limitaciones presupuestarias inmediatas con los requisitos de rendimiento a largo plazo:

Componentes del coste inicial:

| Elemento de coste | Porcentaje del coste total inicial | Consideraciones para los proyectos coreanos |

|---|---|---|

| Material de base | 65-75% | Grado de acero, grosor de pared, requisitos de diámetro |

| Fabricación | 10-15% | Procesos de conformado, soldadura y control de calidad |

| Revestimiento/forrado | 8-12% | Especificaciones de protección contra la corrosión para las condiciones coreanas |

| Pruebas/Inspección | 3-5% | Documentación exhaustiva para el cumplimiento de la normativa coreana |

| Transporte | 5-10% | Logística a los puertos coreanos y a los emplazamientos de los proyectos |

Factores de valor de vida útil:

- Eficacia de la instalación: Los tubos SSAW dimensionalmente consistentes requieren menos ajustes sobre el terreno, lo que reduce el tiempo de instalación y los costes de mano de obra en un 15-20% en comparación con las alternativas de calidad variable.

- Requisitos de mantenimiento: Los tubos SSAW de primera calidad con revestimientos y soldaduras de calidad superior suelen reducir los costes de mantenimiento en un 25-30% a lo largo de una vida útil de 30 años.

- Prolongación de la vida útil: Los tubos SSAW de alta calidad suelen superar la vida útil de diseño en 10-15 años en las aplicaciones de infraestructuras coreanas, lo que retrasa los costosos proyectos de sustitución.

- Fiabilidad operativa: La reducción del tiempo de inactividad por averías o mantenimiento se traduce en un valor significativo en la economía industrial coreana, que consume mucha energía.

- Valor de reventa: La calidad superior del material conserva un mayor valor al final de su vida útil para su reciclaje o reutilización.

Metodología de cálculo del ROI para proyectos energéticos coreanos

Para los planificadores coreanos de infraestructuras energéticas, el siguiente modelo de retorno de la inversión proporciona un marco para las decisiones de inversión en tuberías SSAW:

ROI = (Beneficios a lo largo de la vida – Coste total) / Coste total × 100%

Dónde:

- Prestaciones vitalicias ahorro operativo, reducción del mantenimiento, prolongación de la vida útil y mayor fiabilidad

- Coste total incluye la adquisición inicial, la instalación, el mantenimiento y las consideraciones relativas al final de la vida útil

Análisis del retorno de la inversión de 10 km de tubería 42″ X65 SSAW en el transporte de gas de Corea:

| Categoría de coste/beneficio | Tubería de calidad estándar | Tubería de calidad superior (WUZHOU) | Diferencial |

|---|---|---|---|

| Adquisición inicial | $4,200,000 | $4,620,000 | +$420,000 |

| Instalación | $1,800,000 | $1,530,000 | -$270,000 |

| Mantenimiento (30 años) | $3,600,000 | $2,520,000 | -$1,080,000 |

| Tiempo de inactividad | $900,000 | $360,000 | -$540,000 |

| Valor de extensión de la vida útil | $0 | $1,200,000 | +$1,200,000 |

| Coste/beneficio total durante la vida útil | $10,500,000 | $8,830,000 | -$1,670,000 |

| Rentabilidad de la tubería Premium | 361% |

Este modelo demuestra que la prima del 10% asociada normalmente a los tubos SSAW de mayor calidad produce un rendimiento sustancial de la inversión a lo largo del ciclo de vida de la infraestructura, una consideración crítica para la planificación energética a largo plazo de Corea.

Valor de mitigación del riesgo en las infraestructuras coreanas

Más allá de los cálculos financieros directos, las tuberías SSAW premium aportan un importante valor de mitigación de riesgos en el contexto coreano:

1. Riesgo de cumplimiento de la normativa

- La normativa energética coreana impone estrictas sanciones en caso de incumplimiento

- Las tuberías de primera calidad con documentación exhaustiva reducen la exposición a la normativa

- Valor estimado: 2-3% del coste del proyecto en penalizaciones y retrasos evitados

2. Riesgo medioambiental

- La protección del medio ambiente es cada vez más prioritaria en la política energética coreana

- La integridad superior de las tuberías minimiza el riesgo de fugas y los daños medioambientales

- Valor estimado: 3-5% del coste del proyecto en medidas correctivas y sanciones evitadas

3. Riesgo para la seguridad pública

- La densidad urbana de Corea agrava las consecuencias de las averías en las tuberías

- Los tubos SSAW de alta calidad reducen significativamente la probabilidad de fallo

- Valor estimado: Difícil de cuantificar, pero potencialmente enorme en términos humanos

4. Riesgo de retraso del proyecto

- Los calendarios de construcción coreanos suelen incluir importantes penalizaciones en caso de retraso

- La calidad fiable y constante reduce las complicaciones y los retrasos en la instalación

- Valor estimado: 5-8% del coste del proyecto en penalizaciones por retraso evitadas

El completo sistema de garantía de calidad de WUZHOU’, que incluye una inspección del 100% mediante pruebas de presión de agua, ultrasonidos y rayos X, aborda directamente estos factores de riesgo, proporcionando a los proyectos coreanos beneficios tanto financieros como intangibles.

Consideraciones sobre la financiación de las infraestructuras energéticas coreanas

Los proyectos coreanos de infraestructuras energéticas suelen implicar sofisticadas estructuras de financiación con implicaciones específicas para la adquisición de tuberías:

- Apoyo de la Agencia de Crédito a la Exportación: Muchos proyectos coreanos utilizan la financiación de créditos a la exportación, que a menudo requieren certificaciones de calidad que WUZHOU puede proporcionar.

- Asociaciones público-privadas: Estos acuerdos suelen hacer hincapié en los costes del ciclo de vida más que en la inversión inicial, favoreciendo las soluciones de tuberías de primera calidad.

- Financiación del Banco de Desarrollo: Los bancos internacionales de desarrollo que financian infraestructuras coreanas suelen exigir normas de calidad acordes con las capacidades de WUZHOU’.

- Modelos de financiación empresarial: Las empresas energéticas coreanas utilizan cada vez más modelos de coste total de propiedad en sus decisiones de compra.

- Consideraciones sobre el seguro: La calidad superior de las tuberías puede reducir las primas de seguro de las infraestructuras energéticas coreanas entre un 8 y un 12%.

Estos marcos de financiación reconocen cada vez más la propuesta de valor a largo plazo de los tubos SSAW de primera calidad, apoyando la inversión en productos de calidad como los fabricados por WUZHOU.

Estrategias de optimización de costes para proyectos coreanos

Para los jefes de proyecto coreanos que buscan maximizar el valor al tiempo que gestionan las limitaciones presupuestarias, varias estrategias pueden optimizar la inversión en tuberías SSAW:

- Participación temprana de los proveedores: Involucrar a fabricantes como WUZHOU durante la fase de diseño puede identificar ajustes en las especificaciones que ahorren costes.

- Optimización del volumen: Consolidar los pedidos para maximizar la eficiencia de la producción puede suponer un ahorro de costes del 3-5%.

- Normalización: Limitar las variaciones innecesarias de las especificaciones puede reducir los costes de fabricación entre un 4 y un 6%.

- Integración logística: Coordinar los calendarios de fabricación y construcción puede minimizar los costes de almacenamiento y manipulación.

- Ingeniería del valor: La revisión colaborativa de las especificaciones puede identificar oportunidades para optimizar el uso de materiales sin comprometer el rendimiento.

WUZHOU colabora estrechamente con clientes coreanos para aplicar estas estrategias, ayudando a los proyectos a lograr un equilibrio óptimo entre el coste inicial y el valor de vida útil. Con 13 líneas de producción avanzadas, WUZHOU puede ofrecer una flexibilidad de programación de la producción que respalda estos enfoques de optimización de costes.

Casos prácticos: Éxito de la implantación de tubos SSAW en instalaciones energéticas de Corea del Sur

El examen de las aplicaciones en el mundo real proporciona valiosos conocimientos sobre las ventajas prácticas de los tubos SSAW de primera calidad en las infraestructuras energéticas de Corea del Sur. Los siguientes estudios de casos destacan las implementaciones de éxito y las principales lecciones aprendidas.

Caso práctico 1: Proyecto de ampliación de la terminal de GNL de Incheon

Visión general del proyecto:

- Alcance: 23 km de tubería de transmisión SSAW 48″ X70

- Aplicación: Transporte de gas natural a alta presión

- Calendario del proyecto: 2019-2021

- Requisitos especiales: Consideraciones de diseño sísmico, retos de trazado urbano

Solución para tubos SSAW:

- Especificaciones: 48″ diámetro, 18,3 mm de grosor de pared, grado X70 PSL2

- Características especiales: Mayor resistencia a la fractura (requisitos Charpy de -30°C), sistema de revestimiento especializado

- Garantía de calidad: 100% pruebas ultrasónicas, pruebas hidrostáticas ampliadas

Retos de la aplicación:

- Ajustado calendario de entrega coordinado con la construcción de la terminal

- Logística compleja a través de zonas urbanas congestionadas

- Requisitos estrictos en materia de documentación de calidad

- Condiciones de suelo variables que requieren la personalización del revestimiento

Resultados y beneficios:

- Proyecto finalizado 3 semanas antes de lo previsto

- Cero retrasos en la instalación relacionados con la calidad

- Pruebas hidrostáticas realizadas con una tasa de éxito del 98%

- La inspección posterior a la instalación confirmó la integridad del revestimiento en el 100% de los puntos de prueba

Factores clave del éxito:

- Participación temprana del fabricante en el desarrollo de las especificaciones

- Documentación exhaustiva de control de calidad

- Precisión dimensional constante que reduce los ajustes sobre el terreno

- Asistencia técnica durante la fase de instalación

Al igual que en este caso, WUZHOU ha apoyado importantes proyectos coreanos de infraestructuras energéticas con sus avanzadas capacidades de fabricación y sus completos programas de garantía de calidad, ofreciendo sistemáticamente los excepcionales resultados que exige el sofisticado sector energético de Corea.

Estudio de caso 2: Modernización de la red del complejo industrial de Ulsan

Visión general del proyecto:

- Alcance: 35 km de tubos SSAW de varios diámetros (24″-42″)

- Aplicación: Sistema mixto de transmisión de hidrocarburos

- Calendario del proyecto: 2020-2022

- Requisitos especiales: Limitaciones de la zona industrial, requisito de perturbación mínima

Solución para tubos SSAW:

- Especificaciones: Múltiples diámetros con grado X65, sistema de revestimiento especializado

- Características especiales: Mayor resistencia a la corrosión, longitudes de sección optimizadas

- Garantía de calidad: Paquete completo de pruebas, documentación de trazabilidad

Retos de la aplicación:

- Requisitos de entrega por fases coordinados con el calendario de construcción

- Múltiples variantes de especificaciones para distintos segmentos del sistema

- Requisitos estrictos de protección del medio ambiente cerca de los recursos hídricos

- Interfaz con la infraestructura existente que requiere tolerancias precisas

Resultados y beneficios:

- El sistema se pone en marcha por segmentos, lo que permite un funcionamiento parcial durante la construcción

- La inspección posterior a la instalación no reveló ningún defecto significativo

- El proyecto se completó dentro del presupuesto a pesar de los problemas de la cadena de suministro mundial

- Las pruebas de presión del sistema se han realizado con un 100% de éxito a la primera

Factores clave del éxito:

- Programación flexible de la fabricación

- Calidad homogénea en múltiples especificaciones

- Documentación completa de apoyo a la aprobación reglamentaria

- Asesoramiento técnico durante las fases de modificación del diseño

Las múltiples bases de producción de WUZHOU’ y sus 11 líneas de producción de tubos en espiral proporcionan la flexibilidad de fabricación necesaria para proyectos complejos y de varias fases como éste, garantizando una calidad constante en las distintas especificaciones y plazos de entrega.

Estudio de caso 3: Proyecto piloto de hidrógeno en la provincia de Gyeonggi

Visión general del proyecto:

- Alcance: 8 km de tuberías SSAW de 24″ preparadas para hidrógeno

- Aplicación: Proyecto de demostración de mezcla de hidrógeno

- Calendario del proyecto: 2021-2022

- Requisitos especiales: Metalurgia avanzada para servicio con hidrógeno, factores de seguridad mejorados

Solución para tubos SSAW:

- Especificaciones: 24″ diámetro, grado X65 con química modificada para servicio de hidrógeno

- Características especiales: Revestimiento interno especializado, mayor control de calidad

- Garantía de calidad: Protocolo de pruebas ampliado, 100% de verificación PMI

Retos de la aplicación:

- Nueva aplicación con escasos precedentes en Corea

- La evolución de las normas técnicas exige una fabricación adaptada

- Mayores consideraciones de seguridad para el servicio de hidrógeno

- Procedimientos de soldadura especializados para la instalación sobre el terreno

Resultados y beneficios:

- Puesta en servicio satisfactoria con una mezcla inicial de hidrógeno al 10

- Cero problemas materiales relacionados con el hidrógeno durante el primer año de funcionamiento

- Se ha demostrado que el sistema puede adaptarse al aumento previsto de la mezcla de hidrógeno al 20

- El proyecto establece nuevas referencias de calidad para la infraestructura coreana del hidrógeno

Factores clave del éxito:

- Colaboración en I+D entre el fabricante y el equipo del proyecto

- Mayor garantía de calidad más allá de los requisitos estándar

- Selección y procesamiento de materiales especializados

- Documentación completa de apoyo al desarrollo de casos de seguridad

Este caso ilustra el tipo de aplicaciones innovadoras en las que las capacidades técnicas y el enfoque de calidad de WUZHOU’ aportan un valor excepcional. La experiencia de WUZHOU con materiales de alta calidad y procesos de soldadura avanzados es especialmente relevante para aplicaciones emergentes como las infraestructuras de hidrógeno.

Estudio de caso 4: Proyecto de integración de energías renovables en la isla de Jeju

Visión general del proyecto:

- Alcance: 12 km de tubería de transporte de agua de 36″ SSAW

- Aplicación: El almacenamiento hidroeléctrico por bombeo al servicio de la integración de las energías renovables

- Calendario del proyecto: 2020-2021

- Requisitos especiales: Entorno marino, presión nominal alta, ubicación remota

Solución para tubos SSAW:

- Especificaciones: 36″ diámetro, diseño de alta presión con revestimiento especializado

- Características especiales: Mayor protección contra la corrosión, embalaje de transporte optimizado

- Garantía de calidad: Pruebas ampliadas de idoneidad para aplicaciones marinas

Retos de la aplicación:

- Complejidades logísticas del reparto insular

- Entorno marino agresivo que requiere protección especializada

- Recursos de instalación locales limitados que requieren un trabajo de campo simplificado

- Terreno variable que requiere enfoques de instalación flexibles

Resultados y beneficios:

- La instalación se completó un 15% más rápido de lo previsto gracias a la calidad constante de las tuberías

- Sistema que funciona a la capacidad de diseño con almacenamiento de energía renovable

- Cero problemas de corrosión en la primera inspección de 18 meses

- Proyecto reconocido con el premio coreano a la excelencia en ingeniería medioambiental

Factores clave del éxito:

- Sistema de revestimiento especializado para entornos marinos

- Inspección exhaustiva previa al envío que reduce los problemas de calidad sobre el terreno

- Control dimensional coherente que facilita la instalación

- Coordinación logística para minimizar las necesidades de almacenamiento en tierra

Las amplias capacidades de WUZHOU’, desde el recubrimiento especializado con 2 líneas de producción dedicadas al recubrimiento y revestimiento hasta la coordinación logística optimizada, se ajustan perfectamente a los requisitos de proyectos desafiantes como éste.

Patrones comunes de éxito en las aplicaciones coreanas de tubos SSAW

De estos estudios de casos se desprenden varias pautas relevantes para los futuros proyectos coreanos de infraestructuras energéticas:

- Compromiso temprano de los proveedores: Los proyectos que contaron con la participación de fabricantes de tuberías en la fase inicial de diseño lograron una mejor optimización de la relación coste-rendimiento.

- Documentación exhaustiva sobre calidad: La documentación exhaustiva agilizó considerablemente los procesos de aprobación reglamentaria y verificación de la calidad.

- Integración de la asistencia técnica: La asistencia técnica del fabricante durante las fases de instalación redujo los problemas sobre el terreno y aceleró la finalización del proyecto.

- Coordinación logística: La programación sincronizada de las entregas redujo considerablemente los plazos del proyecto y los costes de almacenamiento.

- Optimización de las especificaciones: El perfeccionamiento colaborativo de las especificaciones técnicas permitió ahorrar costes y mejorar el rendimiento.

Estas pautas ponen de relieve el valor de trabajar con proveedores de tubos SSAW experimentados como WUZHOU, que aportan no sólo capacidad de fabricación, sino también experiencia en aplicaciones y apoyo a los proyectos de infraestructuras energéticas coreanas.

Preguntas frecuentes: Preguntas frecuentes sobre los tubos SSAW para aplicaciones energéticas en Corea del Sur

Preguntas generales sobre los tubos SSAW

P1: ¿Cuáles son las principales ventajas de los tubos SSAW frente a otros tipos de tubos para las infraestructuras energéticas coreanas?

A1: Los tubos SSAW (Spiral Submerged Arc Welded) ofrecen varias ventajas claras para las aplicaciones energéticas coreanas:

- Rentabilidad para grandes diámetros: Los tubos SSAW suelen ser un 15-20% más económicos que los tubos sin soldadura o LSAW en diámetros superiores a 24 pulgadas, habituales en las redes de transmisión coreanas.

- Flexibilidad de la producción: El proceso de fabricación en espiral permite obtener una amplia gama de diámetros y espesores de pared a partir de la misma bobina de acero, lo que permite adaptarla a los requisitos específicos de los proyectos coreanos.

- Eficacia del material: El proceso de soldadura en espiral optimiza el uso de materiales, reduce los residuos y contribuye a los objetivos de sostenibilidad de Corea.

- Resistencia superior a la presión: Cuando se fabrican correctamente, los tubos SSAW ofrecen una excelente contención de la presión para las aplicaciones coreanas de transmisión de alta presión.

- Excelente redondez y rectitud: Los tubos SSAW de calidad mantienen unas propiedades dimensionales constantes, lo que facilita su instalación en el terreno a menudo difícil de Corea.

WUZHOU aprovecha la avanzada tecnología de fabricación para maximizar estas ventajas inherentes, manteniendo al mismo tiempo los más altos niveles de calidad exigidos por los proyectos coreanos.

P2: ¿Cuáles son las limitaciones típicas de los tubos SSAW y cómo se abordan en los proyectos coreanos?

A2: Aunque los tubos SSAW ofrecen numerosas ventajas, hay que tener en cuenta ciertas limitaciones:

| Limitación potencial | Cómo se aborda en los proyectos coreanos | El enfoque de WUZHOU |

|---|---|---|

| Longitud de soldadura helicoidal | Protocolos de inspección END mejorados | 100% de pruebas ultrasónicas de todas las soldaduras |

| Preocupaciones por el servicio de hidrógeno | Química del acero modificada, control de fabricación mejorado | Protocolos de producción especializados para aplicaciones de hidrógeno |

| Aplicaciones del servicio agrio | Procesos de fabricación a medida, selección de materiales | Líneas de producción específicas dedicadas a aplicaciones de servicios ácidos |

| Aplicaciones de muy alta presión | Parámetros de soldadura optimizados, control de calidad mejorado | Proceso avanzado de soldadura a doble cara con control preciso |

Los proyectos coreanos suelen abordar estas consideraciones a través de especificaciones detalladas y requisitos de calidad, que WUZHOU cumple gracias a sus avanzadas capacidades de fabricación y rigurosos programas de garantía de calidad.

P3: ¿Cómo se comportan los tubos SSAW en las zonas sísmicas de Corea del Sur?

A3: Corea del Sur experimenta una actividad sísmica moderada, lo que requiere sistemas de tuberías con una ductilidad y una capacidad de deformación adecuadas. Los tubos SSAW de calidad ofrecen un excelente rendimiento en aplicaciones sísmicas cuando se fabrican conforme a las especificaciones adecuadas:

- Requisitos de tenacidad mejorados (valores Charpy típicos de -20°C a -30°C)

- Valores equivalentes de carbono optimizados para mejorar la soldabilidad

- Relación rendimiento-tracción controlada para una capacidad de deformación superior

- Propiedades de alargamiento mejoradas para mayor ductilidad

Los procesos de fabricación de WUZHOU’ están diseñados específicamente para satisfacer estos requisitos mejorados, con una refrigeración controlada y una gestión química precisa que garantizan unas propiedades mecánicas óptimas para las aplicaciones sísmicas.

Cuestiones técnicas y de especificaciones

P4: ¿Qué normas internacionales y coreanas se aplican a los tubos SSAW en aplicaciones energéticas?

A4: Los tubos SSAW para aplicaciones energéticas coreanas deben cumplir normalmente varias normas:

Normas internacionales:

- API 5L: Especificación del Instituto Americano del Petróleo para tuberías de conducción

- ISO 3183: Norma internacional para las industrias del petróleo y del gas natural

- ASTM A1018: Especificación estándar para chapa y fleje de acero

Normas específicas coreanas:

- KS D 3583: Norma coreana para tubos de acero soldados en espiral

- KS D 3570: Norma coreana para tubos de acero al carbono para servicio a presión

- Especificaciones técnicas de KOGAS para los gasoductos de transporte

WUZHOU mantiene todas las certificaciones pertinentes, incluidas las normas API 5L e ISO, lo que garantiza el pleno cumplimiento de los requisitos tanto internacionales como específicos de Corea. Nuestros productos han superado tanto las normas API 5L como las de la UE, por lo que son totalmente compatibles con las especificaciones de los proyectos coreanos.

P5: ¿Cuáles son las dimensiones habituales de los tubos SSAW en los proyectos coreanos?

A5: La infraestructura energética coreana suele utilizar tubos SSAW dentro de los siguientes rangos dimensionales:

- Diámetro: 508 mm (20″) a 2.540 mm (100″)

- Espesor de pared: de 6 mm a 25 mm

- Longitud: Estándar 12m con longitudes personalizadas disponibles

- Calidades de acero: Normalmente de X42 a X70, siendo X65 y X70 los más comunes en aplicaciones de transmisión

Las 11 líneas especializadas de producción de tubos en espiral de WUZHOU’ pueden producir toda la gama de dimensiones requeridas para los proyectos energéticos coreanos, con especial experiencia en los tubos de gran diámetro y alto grado comúnmente especificados para aplicaciones de transmisión.

P6: ¿Qué sistemas de revestimiento se suelen especificar para los tubos SSAW en las condiciones de Corea del Sur?

A6: Las condiciones ambientales coreanas y los requisitos del proyecto suelen dictar sistemas de revestimiento específicos:

| Aplicación | Sistema de revestimiento común | Requisitos clave de rendimiento |

|---|---|---|

| Tuberías de transmisión enterradas | 3LPE (polietileno de tres capas) | Excelente resistencia al estrés del suelo, compatibilidad CP |

| Instalaciones marítimas y costeras | FBE de doble capa o 3LPP | Protección superior contra la corrosión y resistencia a los impactos |

| Aplicaciones sobre suelo | Sistemas epoxi de alto espesor | Resistencia a los rayos UV, consideraciones estéticas |

| Transmisión de agua | Revestimiento de mortero de cemento + epoxi exterior | Eficacia del flujo interno, protección externa |

Las líneas de producción de revestimientos y recubrimientos de WUZHOU’ pueden aplicar todos estos sistemas de revestimiento según las exigentes especificaciones coreanas, garantizando tanto la calidad estética como el rendimiento funcional en las diversas condiciones ambientales de Corea.

Adquisiciones y proyectos

P7: ¿Cuál es el plazo de entrega habitual de los tubos SSAW para proyectos energéticos coreanos?

A7: Los plazos de entrega de los tubos SSAW para proyectos coreanos varían en función de varios factores:

| Factor | Impacto en el plazo de entrega | Estrategias de optimización |

|---|---|---|

| Volumen del pedido | Los pedidos de mayor volumen (5.000 toneladas) suelen tardar entre 14 y 18 semanas | Entregas escalonadas para ajustarse al calendario de construcción |

| Complejidad de las especificaciones | Los requisitos especiales pueden requerir entre 2 y 4 semanas más | Finalización temprana de las especificaciones |

| Requisitos de las pruebas | Las pruebas mejoradas pueden tardar entre 1 y 3 semanas más | Integrar las pruebas en el calendario de producción |

| Requisitos de revestimiento | Los revestimientos complejos pueden requerir de 2 a 3 semanas más | Procesamiento paralelo siempre que sea posible |

| Logística marítima | Transporte marítimo: 3-4 semanas a Corea | Coordinación con el calendario general del proyecto |

La importante capacidad de producción de WUZHOU’ en 11 líneas de fabricación de tubos en espiral permite optimizar los plazos de fabricación para los proyectos coreanos, consiguiendo a menudo plazos de entrega en el extremo más corto de estos rangos. La capacidad anual de 400.000 toneladas de la empresa garantiza la disponibilidad incluso para los grandes proyectos de infraestructuras coreanos.

P8: ¿Qué documentación suele exigirse para los tubos SSAW en los proyectos energéticos coreanos?

R8: Los proyectos energéticos coreanos suelen requerir una documentación exhaustiva:

Paquete de documentación estándar:

- Certificados de ensayo de materiales (EN 10204 3.1/3.2)

- Registros del proceso de fabricación

- Informes de inspección dimensional

- Informes de exámenes no destructivos

- Certificados de prueba hidrostática

- Informes de inspección de revestimientos

- Documentación de trazabilidad

A menudo se requiere documentación adicional:

- Especificaciones y cualificaciones de los procedimientos de soldadura

- Registros de cualificación de soldadores

- Certificados de materias primas con química completa

- Plan de control de calidad y resultados de las inspecciones

- Recomendaciones de manipulación y almacenamiento

WUZHOU proporciona paquetes completos de documentación que cumplen todos los requisitos coreanos, con informes detallados de materias primas y registros de inspección de calidad para cada tubo soldado en espiral producido. Esta documentación agiliza el proceso de aprobación y aceptación de los proyectos coreanos.

P9: ¿Cómo deben evaluar los directores de proyecto el coste total de propiedad de los tubos SSAW en aplicaciones coreanas?

A9: El análisis del coste total de propiedad para las aplicaciones de tuberías SSAW coreanas debe tener en cuenta:

- Costes iniciales de adquisición:

- Precio base de la tubería

- Costes de revestimiento

- Requisitos especiales de ensayo

- Transporte a Corea

- Costes de instalación:

- Gastos de soldadura sobre el terreno

- Mano de obra de instalación

- Requisitos de las pruebas sobre el terreno

- Posible reelaboración de materiales defectuosos

- Costes operativos:

- Requisitos de inspección y mantenimiento

- Eficacia de bombeo (rugosidad interna)

- Fiabilidad y disponibilidad del sistema

- Frecuencia de sustitución

- Consideraciones sobre el final de la vida:

- Gastos de desmantelamiento

- Valor de reciclado/salvamento

- Requisitos medioambientales

Los tubos SSAW de alta calidad de WUZHOU’ suelen ofrecer ventajas en las categorías 2 a 4, compensando los costes iniciales potencialmente más elevados con importantes ahorros a lo largo de su vida útil. El enfoque de la empresa en la fabricación de calidad y pruebas exhaustivas reduce los costes de instalación, minimiza los gastos operativos y prolonga la vida útil.

Preguntas específicas sobre WUZHOU

Q10: ¿Qué hace que los tubos de acero en espiral WUZHOU sean especialmente adecuados para las aplicaciones energéticas de Corea del Sur?

A10: WUZHOU ofrece varias ventajas claras para los proyectos coreanos de infraestructuras energéticas:

- Excelencia en la fabricación:

- 11 avanzadas líneas de producción de tubos en espiral que garantizan una calidad constante

- 2 líneas de producción especializadas en revestimientos y recubrimientos para una protección completa de las superficies

- Tecnología de producción de vanguardia con un control de calidad preciso

- capacidad anual de 400.000 toneladas que garantiza la disponibilidad para grandes proyectos coreanos

- Garantía de calidad:

- inspección del 100% de cada tubería (pruebas hidrostáticas, ultrasónicas y de rayos X)

- Ensayos y certificación exhaustivos de materiales

- Documentación de calidad detallada que cumpla los requisitos coreanos

- Trazabilidad completa desde la materia prima hasta el producto acabado

- Capacidades técnicas:

- Experiencia con las calidades X65/X70 especificadas habitualmente en los proyectos coreanos

- Experiencia en tuberías de gran diámetro (hasta 3500 mm) necesarias para las líneas de transmisión

- Capacidades avanzadas de revestimiento para las condiciones ambientales de Corea

- Flexibilidad de fabricación para satisfacer los requisitos específicos de cada proyecto

- Certificación y conformidad:

- Certificación API 5L que garantiza el cumplimiento de las normas internacionales

- Certificaciones ISO 9001 e ISO 14001 que demuestran la calidad del sistema de gestión

- Cumplimiento de las normas de la UE como garantía adicional de calidad

- Reconocimiento como una de las 10 mejores marcas chinas de tubos de acero, lo que valida su reputación de calidad

Estas capacidades hacen que WUZHOU esté especialmente bien preparada para satisfacer los exigentes requisitos de los proyectos de infraestructuras energéticas surcoreanos, aportando tanto excelencia técnica como valor comercial.

P11: ¿Qué apoyo técnico presta WUZHOU a los proyectos energéticos coreanos?

A11: WUZHOU ofrece asistencia técnica completa durante todo el ciclo de vida del proyecto:

- Consulta previa al proyecto: Orientación para la selección de materiales, optimización de especificaciones, recomendaciones para aplicaciones específicas

- Fase de fabricación: Actualizaciones periódicas de los progresos, oportunidades de inspección, disposiciones sobre testigos de pruebas

- Coordinación de la entrega: Planificación logística, optimización del transporte, preparación de documentación

- Soporte de instalación: Asesores técnicos disponibles para preguntas sobre el terreno, recomendaciones de soldadura

- Asistencia posterior a la instalación: Asistencia en la puesta en marcha, recomendaciones operativas, servicio de garantía

Este completo paquete de asistencia garantiza que los proyectos coreanos reciban no sólo productos de calidad, sino también la experiencia necesaria para optimizar su aplicación y rendimiento.

P12: ¿Cómo garantiza WUZHOU la calidad constante de los tubos destinados a proyectos coreanos?

A12: WUZHOU mantiene una calidad excepcional gracias a un enfoque múltiple:

- Control de materias primas:

- Estricto sistema de cualificación de proveedores

- inspección del 100% de los materiales entrantes

- Análisis químico detallado antes de la producción

- Control del proceso de fabricación:

- Sistemas automatizados de control de la producción

- Verificación continua de parámetros

- Control dimensional en proceso

- Garantía de calidad de la soldadura:

- Procedimientos de soldadura y soldadores cualificados

- Tecnología de control de soldaduras en línea

- Tratamiento térmico posterior a la soldadura cuando se especifique

- Pruebas exhaustivas:

- pruebas hidrostáticas al 100% de todas las tuberías

- examen ultrasónico del 100% de las soldaduras

- Pruebas de rayos X para la inspección detallada de soldaduras

- Verificación de las propiedades mecánicas

- Inspección final:

- Verificación dimensional

- Inspección visual

- Inspección de revestimientos

- Revisión final de la documentación

Este enfoque sistemático garantiza que todas las tuberías de WUZHOU enviadas a proyectos coreanos cumplen las normas de calidad más exigentes, apoyando la fiabilidad e integridad de las infraestructuras energéticas críticas de Corea.

En conclusión, los tubos SSAW desempeñan un papel crucial en las infraestructuras energéticas de Corea del Sur, ya que proporcionan las capacidades de transmisión esenciales que requiere esta economía avanzada. A medida que Corea continúe su transición energética y la modernización de sus infraestructuras, la demanda de tubos SSAW fiables y de alta calidad seguirá creciendo.

WUZHOU está preparada para apoyar este desarrollo con su avanzada capacidad de fabricación, su completa garantía de calidad y su servicio orientado al cliente. Como fabricante líder con 13 líneas de producción avanzadas, amplias capacidades de ensayo y certificaciones internacionales, WUZHOU ofrece a los proyectos coreanos la combinación perfecta de calidad, fiabilidad y valor.

Para los compradores al por mayor, distribuidores, empresas de ingeniería y empresas de energía que participan en el desarrollo de la infraestructura de Corea, la asociación con WUZHOU proporciona acceso a soluciones de tubería SSAW de clase mundial respaldados por la experiencia, el servicio y el compromiso inquebrantable con la calidad.