Comprender el proceso de fabricación de los tubos de acero soldados en espiral: Una guía completa

18 de marzo de 2025

Comparte este artículo

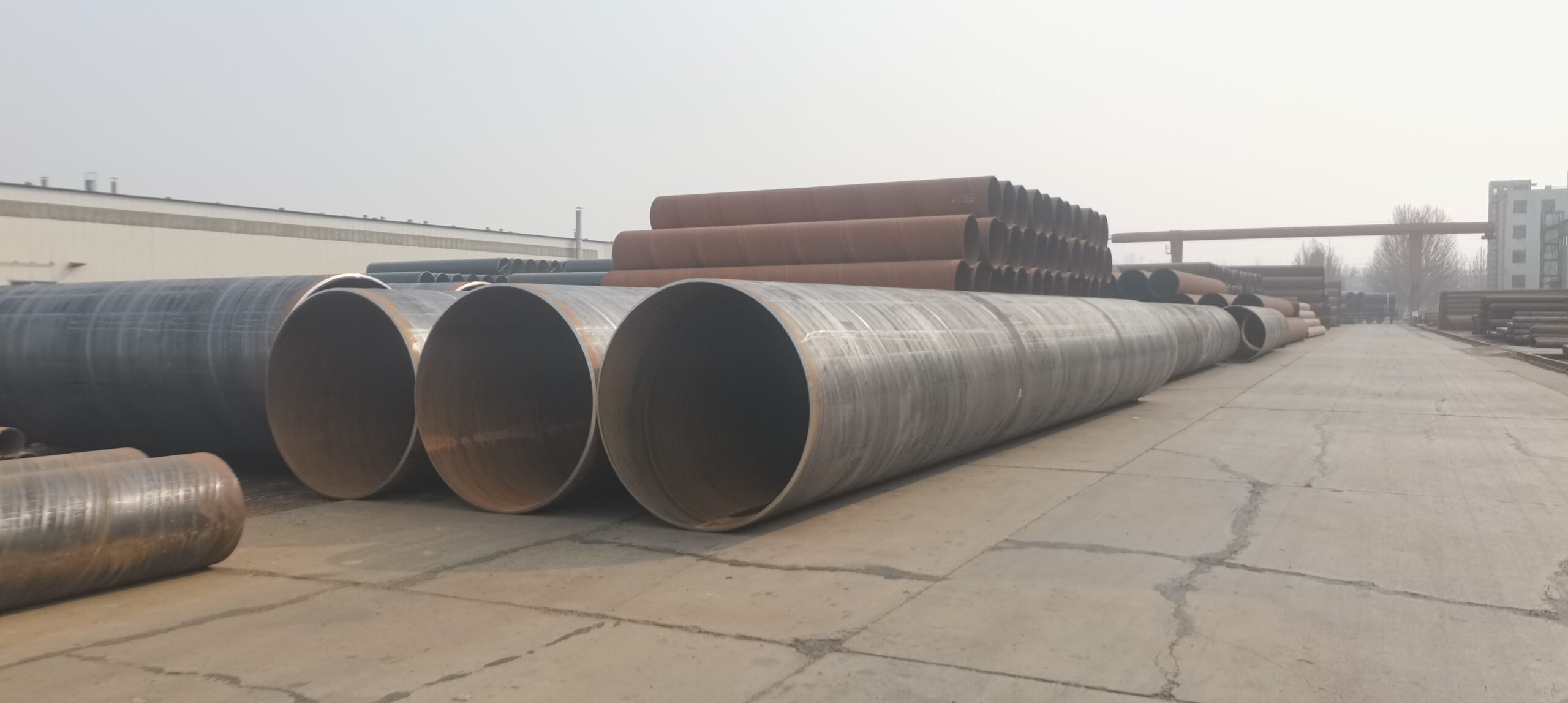

Introducción a la fabricación de tubos de acero soldados en espiral

Los tubos de acero soldados en espiral representan una de las innovaciones más significativas en la tecnología de tuberías, ya que ofrecen una notable relación resistencia-peso, rentabilidad y versatilidad para aplicaciones de gran diámetro. Para los compradores al por mayor, los distribuidores y los directores de proyectos de sectores que van desde el petróleo y el gas hasta la transmisión de agua, comprender las complejidades de la fabricación de tubos en espiral es crucial para tomar decisiones de compra informadas.

A diferencia de los tubos soldados longitudinalmente, que presentan una costura recta a lo largo de su longitud, los tubos soldados en espiral se caracterizan por su distintiva costura de soldadura helicoidal que gira en espiral alrededor de la circunferencia del tubo. Este enfoque de fabricación único no sólo permite un uso eficiente del material, sino que también posibilita la producción de tubos de mayor diámetro que con los métodos tradicionales.

El mercado mundial de tubos soldados en espiral sigue en expansión, con proyecciones que indican una tasa de crecimiento anual compuesto (TCAC) de aproximadamente el 7,2% entre 2023 y 2028. Este crecimiento está impulsado principalmente por el aumento del desarrollo de infraestructuras, la expansión de las actividades de exploración de petróleo y gas, y la creciente demanda de soluciones de gestión del agua en todo el mundo.

Por qué los profesionales del sector prefieren cada vez más los tubos soldados en espiral:

- Eficiencia material: El proceso de fabricación en espiral permite un uso óptimo de las bobinas de acero, reduciendo los residuos y los costes globales de producción.

- Resistencia superior a la presión: El patrón de soldadura helicoidal distribuye la presión de forma más uniforme por toda la estructura del tubo.

- Flexibilidad de producción: Los fabricantes pueden producir varios diámetros a partir del mismo ancho de bobina de acero, lo que ofrece una mayor versatilidad.

- Logística mejorada: Los tubos de mayor diámetro pueden fabricarse con bobinas de acero de menor anchura, lo que facilita el transporte de la materia prima.

- Relación coste-eficacia: Para los compradores al por mayor, los tubos en espiral suelen ofrecer una solución más económica para aplicaciones de gran diámetro que los tubos soldados longitudinalmente o sin soldadura.

Como comprador mayorista o ingeniero de proyectos, asociarse con un fabricante de tubos de acero en espiral establecido como WUZHOU garantiza el acceso a productos de primera calidad que cumplen las normas internacionales, manteniendo al mismo tiempo precios competitivos. WUZHOU, la marca líder de Cangzhou Spiral Steel Pipes Group, se ha establecido como un punto de referencia para la calidad y la fiabilidad en la industria de tubos de acero en espiral, con instalaciones de producción de última generación capaces de fabricar tubos con especificaciones exactas.

Evolución de la fabricación de tubos soldados en espiral

La tecnología de fabricación de tubos de acero soldados en espiral ha evolucionado considerablemente desde su introducción. Los primeros métodos de fabricación consistían en un conformado en espiral básico con capacidades de soldadura limitadas, mientras que las líneas de producción modernas, como las de WUZHOU, incorporan automatización avanzada, sistemas de control precisos y tecnologías de soldadura sofisticadas.

| Década | Avance de la tecnología de fabricación | Impacto en la industria |

|---|---|---|

| años 1930-1940 | Introducción al conformado en espiral básico | Producción limitada de tubos de gran diámetro |

| Década de 1950-1960 | Desarrollo de la soldadura por arco sumergido para tubos en espiral | Mejora de la calidad de la soldadura y de la velocidad de producción |

| 1970s-1980s | Introducción de la soldadura por arco sumergido de doble cara | Integridad estructural y presión nominales mejoradas |

| Década de 1990-2000 | Sistemas de conformado y soldadura controlados por ordenador | Mayor precisión y coherencia en la producción |

| 2010s-Presente | Automatización avanzada y control de calidad integrado | Mayor calidad, producción más rápida y menos defectos |

En la actualidad, las instalaciones de fabricación de tubos en espiral soldados, como las modernas bases de producción de WUZHOU, representan la culminación de casi un siglo de avances tecnológicos. Con 11 líneas dedicadas a la producción de tubos en espiral y 2 líneas especializadas de revestimiento y recubrimiento, WUZHOU ejemplifica el enfoque moderno de la fabricación de tubos en espiral de acero de alta capacidad y calidad.

Materias primas y normas de calidad en la producción de tubos de acero en espiral

La calidad de la soldadura en espiral acero de los tubos comienza con la selección de las materias primas adecuadas. Para los compradores y distribuidores mayoristas, comprender la relación entre las especificaciones de la materia prima y el rendimiento del producto final es esencial para adquirir tuberías que cumplan los requisitos del proyecto y las expectativas de longevidad.

Calidades de acero y sus propiedades

Las calidades de acero más utilizadas en la fabricación de tubos soldados en espiral son:

Grados de acero al carbono:

- Grados API 5L (X42, X46, X52, X56, X60, X65, X70, X80) – Estas calidades, normalizadas por el American Petroleum Institute, se utilizan ampliamente en el transporte de petróleo y gas. El número indica el límite elástico mínimo en miles de libras por pulgada cuadrada.

- ASTM A53 – Común para conductos de agua y gas en aplicaciones comerciales

- ASTM A252 – Diseñado específicamente para aplicaciones de pilotaje de tuberías

- EN 10219 – Norma europea para perfiles huecos estructurales soldados conformados en frío

Grados de servicio a alta temperatura:

- ASTM A106 – Para aplicaciones de servicio a alta temperatura

- ASTM A335 – Acero al cromo-molibdeno para aplicaciones de alta temperatura

El compromiso de WUZHOU’ con la calidad comienza con la cuidadosa selección de estas materias primas. Cada bobina de acero utilizada en su proceso de fabricación se somete a una inspección rigurosa y se suministra con informes exhaustivos de los materiales que documentan la composición química y las propiedades mecánicas.

Requisitos de composición química

La composición química del acero utilizado para las tuberías soldadas en espiral influye significativamente en sus características de rendimiento. En la tabla siguiente se describen los requisitos de composición típicos de las calidades de tuberías más comunes:

| Elemento | X42 (%) | X52 (%) | X60 (%) | X70 (%) |

|---|---|---|---|---|

| Carbono (C) | ≤0.22 | ≤0.20 | ≤0.18 | ≤0.17 |

| Manganeso (Mn) | ≤1.40 | ≤1.40 | ≤1.60 | ≤1.70 |

| Fósforo (P) | ≤0.025 | ≤0.025 | ≤0.020 | ≤0.020 |

| Azufre (S) | ≤0.015 | ≤0.015 | ≤0.010 | ≤0.010 |

| Silicio (Si) | ≤0.45 | ≤0.45 | ≤0.45 | ≤0.45 |

| Niobio (Nb) | * | * | * | ≤0.05 |

| Vanadio (V) | * | * | * | ≤0.06 |

| Titanio (Ti) | * | * | * | ≤0.04 |

*Nota: los elementos de microaleación como el Nb, el V y el Ti se añaden a menudo en cantidades controladas a los tubos de calidad superior para aumentar su resistencia y tenacidad.

En WUZHOU, cada lote de materia prima se somete a pruebas para garantizar el cumplimiento de estos estrictos requisitos de composición química. Su sofisticado sistema de gestión de la calidad, certificado según las normas ISO 9001, garantiza que sólo el acero que cumple estas exigentes especificaciones entra en el proceso de producción.

Propiedades mecánicas y normas

Las propiedades mecánicas de los tubos de acero soldados en espiral determinan su comportamiento bajo presión y en diversas condiciones ambientales. Entre las propiedades clave se incluyen:

- Límite elástico – Tensión a la que el material comienza a deformarse plásticamente

- Resistencia a la tracción – La tensión máxima que puede soportar el material antes de fallar

- Alargamiento – Una medida de la ductilidad y la conformabilidad

- Resistencia al impacto – Resistencia a la fractura frágil, especialmente importante en aplicaciones en climas fríos

Normas internacionales que regulan la fabricación de tubos de acero en espiral:

- API 5L – Norma del Instituto Americano del Petróleo para tuberías de conducción

- ISO 3183 – Norma internacional para tuberías de acero para sistemas de transporte por tuberías

- EN 10208 – Norma europea sobre tubos de acero para fluidos combustibles

- ASTM A1018 – Especificación normalizada para chapas y bandas de acero, bobinas de gran espesor

- GB/T 9711 – Norma nacional china para las industrias del petróleo y el gas natural

Los tubos de acero soldados en espiral de WUZHOU’ se fabrican en pleno cumplimiento de estas normas internacionales. Su doble cara soldada por arco sumergido tubos de acero en espiral han pasado la norma API 5L del Instituto Americano del Petróleo y cumplir con las normas de la Unión Europea también. Para los compradores al por mayor, esta adhesión a las normas mundiales garantiza que los tubos adquiridos de WUZHOU serán aceptados para proyectos en todo el mundo.

Proceso de fabricación paso a paso de los tubos de acero soldados en espiral

Comprender el proceso de fabricación proporciona a los compradores mayoristas y a los ingenieros de proyectos información valiosa sobre los factores determinantes de la calidad y las posibles limitaciones de los tubos de acero soldados en espiral. El siguiente desglose detallado explica cómo el acero en bruto se transforma en tubos soldados en espiral acabados en las avanzadas instalaciones de fabricación de WUZHOU’.

1. Preparación e inspección de materias primas

El proceso de fabricación comienza con la cuidadosa selección y preparación de las bobinas de acero:

- Recepción y documentación: Las bobinas de acero se entregan con certificados de fábrica que detallan su composición química, propiedades mecánicas e historial de fabricación.

- Inspección visual: Los técnicos examinan las bobinas en busca de defectos superficiales, daños o irregularidades.

- Verificación dimensional: La anchura y el grosor de las bobinas se miden para garantizar que cumplen las especificaciones.

- Pruebas de materiales: Las muestras pueden someterse a pruebas adicionales para verificar sus propiedades.

En WUZHOU, cada bobina se inspecciona minuciosamente antes de entrar en producción. Su compromiso con la calidad comienza en este primer paso crucial, con una documentación exhaustiva que se mantiene durante todo el proceso para garantizar la trazabilidad.

2. Preparación de bordes y recorte

Antes del conformado, los bordes de las bobinas de acero deben prepararse adecuadamente:

- Fresado/recorte de bordes: Los bordes de la bobina de acero se mecanizan o recortan para crear superficies limpias y uniformes para la soldadura.

- Biselado de cantos: Para materiales más gruesos, los bordes están biselados para facilitar la penetración adecuada de la soldadura.

- Limpieza: Los bordes se limpian para eliminar cualquier contaminante que pueda afectar a la calidad de la soldadura.

WUZHOU emplea equipos de preparación de bordes de precisión que garantizan unas condiciones óptimas de los bordes para obtener soldaduras fuertes y consistentes, un factor crítico para la integridad y longevidad de los tubos.

3. Proceso de conformado: Creación de la forma en espiral

La característica forma en espiral se forma mediante un proceso continuo:

- Desaceitado: La bobina de acero se desenrolla y se aplana.

- Precalentamiento: Para determinadas calidades o materiales más gruesos, el acero puede precalentarse para aumentar su conformabilidad.

- Formación de espirales: El fleje de acero plano pasa por unos rodillos de conformación que lo doblan gradualmente hasta darle una forma helicoidal.

- Control del diámetro: El ángulo con el que la banda entra en la sección de conformado determina el diámetro del tubo.

- Soldadura por puntos: Una soldadura preliminar asegura la forma espiral antes del proceso de soldadura principal.

Los equipos de conformado de WUZHOU’ permiten controlar con precisión el ángulo de la espiral y el diámetro del tubo resultante. Con 11 avanzadas líneas de producción de tubos en espiral, pueden producir eficientemente tubos de varios diámetros para satisfacer los diversos requisitos de los proyectos.

4. Proceso de soldadura: Creación de la fuerte costura en espiral

La fase de soldadura es quizá la más crítica para determinar la integridad estructural del tubo:

- Soldadura interior: La primera soldadura por arco sumergido se aplica en la costura interior.

- Soldadura exterior: Se aplica una segunda soldadura por arco sumergido a la costura exterior.

- Parámetros de soldadura: Los factores críticos controlados durante la soldadura incluyen:

- Corriente y tensión

- Velocidad de desplazamiento

- Velocidad de avance del hilo

- Cobertura de flujo

- Temperatura de precalentamiento/interpass

El proceso de soldadura por arco sumergido (SAW) en detalle:

- Se introduce un electrodo de hilo continuo en la junta

- Se forma un arco eléctrico entre el alambre y los bordes del tubo

- El arco y el baño de soldadura están sumergidos bajo una capa de fundente granular

- El fundente se funde para formar una escoria protectora sobre la soldadura

- El resultado es una soldadura de alta calidad y penetración profunda

WUZHOU emplea una avanzada tecnología de soldadura por arco sumergido de doble cara que garantiza una fusión y penetración completas de la soldadura. Este proceso produce soldaduras que cumplen o superan la resistencia del material base, un factor crucial para la seguridad y la longevidad de las tuberías.

La importancia de una soldadura adecuada en la fabricación de tubos en espiral

El proceso de soldadura representa la fase más crítica en la fabricación de tubos en espiral, ya que influye directamente en las características de rendimiento del tubo:

| Aspecto de la soldadura | Impacto en la calidad de las tuberías | El enfoque de WUZHOU |

|---|---|---|

| Penetración de la soldadura | Determina la resistencia y la integridad de las juntas | El proceso SAW de doble cara garantiza una penetración total |

| Control de entrada de calor | Afecta a las propiedades mecánicas en la zona afectada por el calor | Control preciso de los parámetros de soldadura |

| Selección de flujo | Influye en la química de la soldadura y la prevención de defectos | Materiales fundentes de primera calidad con una composición óptima |

| Refuerzo de soldadura | Contribuye a la resistencia global a la presión | Control cuidadoso para mantener un refuerzo uniforme |

| Frecuencia de inspección | Garantiza la coherencia en toda la producción | inspección del 100% de las soldaduras con métodos END avanzados |

El compromiso de WUZHOU’ con la excelencia en la soldadura ha consolidado su reputación como principal fabricante de tubos de acero soldados en espiral de alta calidad. Su estricto cumplimiento de las normas internacionales de soldadura y control de calidad integral aseguran que los compradores al por mayor reciben productos con integridad de la soldadura fiable y el rendimiento.

Tecnología y equipos avanzados en la fabricación moderna de tubos en espiral

La producción de tubos de acero soldados en espiral de alta calidad exige tecnología y equipos sofisticados. Para los compradores al por mayor y los profesionales del sector, comprender estos aspectos tecnológicos es crucial para evaluar las capacidades de un fabricante y la calidad del producto resultante.

Tecnología de conformado de vanguardia

La fabricación moderna de tubos en espiral se basa en equipos de conformado de precisión:

- Sistemas de conformado controlados por CNC: Los sistemas de control numérico por ordenador garantizan una precisión dimensional exacta durante el proceso de conformado, manteniendo diámetros y espesores de pared constantes en todas las series de producción.

- Equipos de conformado en ángulo variable: Las máquinas de conformado avanzadas permiten a los fabricantes ajustar el ángulo de la espiral en tiempo real, lo que posibilita la producción de tubos de distintos diámetros a partir de bobinas de acero del mismo ancho sin largos tiempos de cambio.

- Sistemas de conformado multibobina: Estos sistemas utilizan múltiples rodillos de conformado para dar forma gradualmente a la banda de acero en la configuración en espiral, minimizando la tensión sobre el material y reduciendo el riesgo de deformación o defectos.

WUZHOU ha realizado importantes inversiones en tecnología de conformado de última generación en sus 11 líneas de producción de tubos en espiral. Sus avanzados equipos les permiten producir tubos con una precisión dimensional y una calidad superficial excepcionales, un factor crítico para aplicaciones en las que son esenciales unas características de ajuste y flujo precisas.

Tecnologías avanzadas de soldadura

La evolución de la tecnología de soldadura ha mejorado considerablemente la calidad y la eficacia de producción de los tubos soldados en espiral:

Sistemas de soldadura por arco sumergido multihilo:

- Utiliza varios alambres para aumentar la velocidad de deposición y de producción

- Proporciona un mejor control de la entrada y penetración del calor

- Permite soldaduras de mayor calidad para aplicaciones críticas

Configuraciones de soldadura en tándem y doble:

- Configuración en tándem: Dos cables en secuencia con fuentes de alimentación independientes

- Configuración doble: Dos cables paralelos con una sola fuente de alimentación

- Ambos aumentan la velocidad de producción manteniendo la calidad de la soldadura

Ajuste automatizado de los parámetros de soldadura:

- Control en tiempo real de las condiciones de soldadura

- Ajuste automático de los parámetros para optimizar la calidad de la soldadura

- Reduce la dependencia del operador y garantiza resultados coherentes

Sistemas de seguimiento del cordón de soldadura:

- Los sensores láser u ópticos rastrean la posición de la unión soldada

- Ajusta automáticamente la posición del cabezal de soldadura para mantener una alineación óptima

- Garantiza una calidad constante de la soldadura incluso con pequeñas variaciones en el conformado del tubo

WUZHOU emplea estas avanzadas tecnologías de soldadura en todas sus instalaciones de producción. Su inversión en sistemas de soldadura por arco sumergido de doble cara garantiza que sus tubos de acero en espiral presenten soldaduras de excepcional calidad e integridad estructural. Para los compradores al por mayor, esto se traduce en tubos con índices de presión superiores, mayor vida útil y mejores márgenes de seguridad.

Manipulación automatizada de materiales y líneas de producción

Los sistemas automatizados de manipulación de materiales aumentan la eficacia y la uniformidad en la fabricación de tubos en espiral:

- Sistemas automatizados de carga de bobinas: Reducir la manipulación manual y los posibles daños a las materias primas

- Líneas de producción continua: Minimizar las interrupciones de la producción y mantener una calidad constante

- Equipos robotizados de manipulación: Garantiza el posicionamiento y movimiento precisos de los tubos durante la producción

- Control dimensional automatizado: Control y ajuste continuos de las dimensiones de los tubos durante la fabricación

- Sistemas integrados de ejecución de la fabricación (MES): Coordinar todos los aspectos de la producción para lograr una eficacia óptima

Con 13 avanzadas líneas de producción (11 para tubos de acero en espiral y 2 para revestimiento y recubrimiento), WUZHOU ejemplifica el enfoque moderno de la fabricación de tubos en espiral de alta eficiencia. Sus sistemas automatizados garantizan una calidad constante al tiempo que alcanzan una impresionante capacidad de producción anual de 400.000 toneladas de tubos soldados en espiral.

Tecnologías de revestimiento y recubrimiento

Los fabricantes modernos de tubos en espiral incorporan tecnologías avanzadas de revestimiento y recubrimiento para mejorar el rendimiento y la longevidad de los tubos:

Sistemas de revestimiento exterior:

- polietileno de 3 capas (3LPE): Proporciona una protección superior contra la corrosión

- Epoxi unido por fusión (FBE): Ofrece una excelente resistencia química

- Epoxi de alquitrán de hulla: Adecuado para aplicaciones marinas y subterráneas

- Revestimiento de mortero de cemento: Proporciona protección mecánica y flotabilidad negativa

Opciones de revestimiento interior:

- Revestimiento epoxi: Evita la corrosión interna y mejora la eficacia del flujo

- Revestimiento de mortero de cemento: Protege contra la corrosión interna y la abrasión

- Forro de poliuretano: Proporciona una excelente resistencia a la abrasión para el transporte de lodos

Las líneas de producción especializadas en revestimientos y recubrimientos de WUZHOU’ representan su compromiso de ofrecer soluciones completas para tuberías. Su capacidad para ofrecer diversas opciones de revestimiento y recubrimiento permite a los compradores mayoristas adquirir tuberías adaptadas específicamente a sus entornos de aplicación, desde suelos corrosivos hasta lodos abrasivos.

| Tipo de revestimiento | Entorno de aplicación | Principales ventajas | Cumplimiento de las normas |

|---|---|---|---|

| 3LPE | Subterráneo, marino | Protección superior contra la corrosión y resistencia a los impactos | DIN 30670, CSA Z245.21 |

| FBE | Exposición química, alta temperatura | Resistencia química, estabilidad térmica | API RP 5L2, NACE RP0394 |

| Mortero de cemento | Transmisión de agua, marina | Protección mecánica, flotabilidad negativa | AWWA C205, EN 10298 |

| Revestimiento epoxi | Agua potable, aceite & gas | Eficacia de caudal, resistencia a la corrosión | AWWA C210, NSF/ANSI 61 |

Procedimientos de control de calidad y ensayo de los tubos de acero en espiral

El control de calidad representa uno de los aspectos más críticos de la fabricación de tubos soldados en espiral. Para los compradores al por mayor y los ingenieros de proyectos, comprender el régimen de pruebas de un fabricante proporciona información sobre las expectativas de fiabilidad y rendimiento del producto final.

Métodos de ensayo no destructivos

La fabricación moderna de tubos en espiral incorpora pruebas exhaustivas no destructivas para garantizar la integridad de las soldaduras y la calidad de los tubos:

Pruebas ultrasónicas (UT):

- Utiliza ondas sonoras de alta frecuencia para detectar defectos internos

- Puede identificar falta de fusión, inclusiones, grietas y porosidad

- Normalmente automatizado para la inspección del 100% de los cordones de soldadura

- Proporciona registros digitales para una documentación de calidad

Pruebas radiográficas (RT):

- Utiliza rayos X o gamma para detectar defectos internos

- Proporciona registros permanentes de la calidad de la soldadura

- Puede identificar porosidad, inclusiones, grietas y falta de fusión

- Puede utilizarse para comprobaciones puntuales o para inspecciones al 100%, en función de las necesidades

Inspección por partículas magnéticas (MPI):

- Detecta defectos superficiales y cercanos a la superficie

- Especialmente eficaz para encontrar grietas en materiales ferromagnéticos

- Puede realizarse en extremos de tuberías y reparaciones de soldaduras

Pruebas de corrientes de Foucault:

- Detecta defectos superficiales tanto en la soldadura como en el material base

- Puede funcionar a altas velocidades para una inspección continua

- Especialmente eficaz para detectar defectos superficiales

En WUZHOU, cada tubo de acero en espiral se somete a rigurosas pruebas no destructivas, incluyendo ultrasonidos, rayos X y pruebas de presión hidrostática. Este enfoque integral garantiza que sólo los tubos que cumplen las normas de calidad más estrictas llegan a sus clientes.

Pruebas mecánicas y físicas

Más allá de los métodos no destructivos, las pruebas mecánicas y físicas validan la integridad estructural y las características de rendimiento de los tubos soldados en espiral:

Pruebas de presión hidrostática:

- Verifica la capacidad de la tubería para soportar las presiones de funcionamiento

- Normalmente se realiza a presiones 1,5-2 veces superiores a la presión de diseño

- Prueba la integridad tanto de la costura de soldadura como del material base

- Imprescindible para garantizar la seguridad en aplicaciones a presión

Pruebas mecánicas de muestras de producción:

- Pruebas de tracción: Verifica el límite elástico, la resistencia a la tracción y el alargamiento

- Pruebas de flexión: Evalúa la ductilidad y la integridad de la soldadura

- Pruebas de impacto: Evalúa la tenacidad a temperaturas de funcionamiento

- Pruebas de dureza: Garantiza la coherencia de las propiedades de los materiales

- Prueba de aplanamiento: Evalúa la calidad de las soldaduras y la ductilidad de los tubos

Inspección dimensional:

- Diámetro y ovalidad: Asegura que la tubería cumple las especificaciones dimensionales

- Espesor de pared: Verifica la consistencia del grosor de la pared alrededor de la circunferencia

- Rectitud: Confirma que el tubo cumple los requisitos de rectitud

- Escuadra final: Garantiza el ajuste correcto durante el montaje de las tuberías

El compromiso de WUZHOU’ con la calidad incluye pruebas mecánicas y físicas exhaustivas de sus tubos soldados en espiral. Su laboratorio de pruebas está equipado con equipos avanzados para realizar todas las pruebas requeridas de acuerdo con las normas internacionales, proporcionando a los compradores al por mayor con garantía documentada de la calidad del producto.

Sistemas de gestión de la calidad y certificación

Un sólido sistema de gestión de la calidad sirve de base para una excelencia constante en la fabricación:

- Sistema de gestión de la calidad ISO 9001: Proporciona un enfoque estructurado de la gestión de la calidad

- Sistema de gestión de la calidad API Q1: Diseñado específicamente para fabricantes de la industria del petróleo y el gas

- Documentación y trazabilidad: Mantiene registros desde la materia prima hasta el producto acabado

- Procesos de mejora continua: Aborda sistemáticamente los problemas de calidad y mejora los métodos de producción

- Inspección por terceros: Verificación independiente del cumplimiento de las especificaciones

Las operaciones de fabricación de WUZHOU’ están certificadas según las normas ISO 9001 e ISO 14001, lo que demuestra su compromiso con la gestión de la calidad y la responsabilidad medioambiental. Sus tubos soldados en espiral han recibido la certificación API 5L del Instituto Americano del Petróleo y cumplen las normas de la Unión Europea, por lo que son adecuados para proyectos globales con estrictos requisitos de calidad.

Documentación e informes de inspección

Una documentación exhaustiva proporciona a los compradores mayoristas la verificación de la calidad del producto:

- Informes de ensayo de materiales (MTR): Documentar la composición química y las propiedades mecánicas del material de base

- Registros del proceso de fabricación: Seguimiento de los parámetros de producción y controles de calidad durante la fabricación

- Informes de ensayos no destructivos: Documentar los resultados de UT, RT y otros métodos END

- Informes de inspección dimensional: Verificar el cumplimiento de las especificaciones dimensionales

- Certificados de prueba hidrostática: Confirmar el éxito de la prueba de presión

- Certificado de conformidad: Resume la conformidad con las normas y especificaciones aplicables

WUZHOU proporciona documentación de inspección completa para cada lote de tubos soldados en espiral, incluyendo informes de materias primas e informes detallados de inspección de calidad. Este enfoque transparente de la garantía de calidad ofrece a los compradores mayoristas confianza en la integridad y el rendimiento de sus productos.

WUZHOU’Capacidades y normas de fabricación superiores

Como marca líder de Cangzhou Spiral Steel Pipes Group, WUZHOU se ha establecido como referente de calidad e innovación en la industria de los tubos soldados en espiral. Sus capacidades de fabricación superiores ofrecen a los compradores al por mayor y a los gestores de proyectos ventajas convincentes a la hora de abastecerse de productos para tuberías de alta calidad.

Instalaciones de producción de última generación

La infraestructura de fabricación de WUZHOU’ representa una importante ventaja competitiva:

- 13 Líneas de producción avanzadas: Incluye 11 líneas dedicadas a tubos en espiral y 2 líneas especializadas de revestimiento y recubrimiento

- 4 Bases de producción: Estratégicamente situada para servir con eficacia a los mercados nacionales e internacionales

- 6 Talleres de producción: Instalaciones especializadas para diferentes aspectos de la fabricación de tubos

- Capacidad anual de 400.000 toneladas: Gran capacidad de producción para satisfacer las necesidades de grandes proyectos

- Producción multiespecífica: Capacidad para producir tubos en espiral en una amplia gama de dimensiones y especificaciones

Esta amplia huella de fabricación permite a WUZHOU cumplir los exigentes plazos de entrega de proyectos a gran escala, manteniendo al mismo tiempo un estricto control de calidad. Para los compradores mayoristas que gestionan grandes iniciativas de infraestructuras, esta capacidad de producción garantiza un suministro fiable incluso para los proyectos más ambiciosos.

Amplia gama de productos y especificaciones

La versatilidad de fabricación de WUZHOU’ les permite ofrecer una amplia gama de especificaciones de tubos soldados en espiral:

Diámetro:

- De 219 mm a 3500 mm (de 8 pulgadas a 138 pulgadas)

- Capacidad para producir diámetros personalizados para aplicaciones especializadas

Gama de espesores de pared:

- De 5 mm a 25 mm (de 0,197 pulgadas a 0,984 pulgadas)

- Control de precisión de la consistencia del espesor en todo el tubo

Calidades de acero disponibles:

- Grados API 5L: X42, X46, X52, X56, X60, X65, X70, X80

- Normas ASTM: A53, A252, A106, A139, A1018

- Normas europeas: EN 10219, EN 10208

- Calidades especiales para aplicaciones específicas

Longitudes de tubo:

- Longitudes estándar de 12 m (40 pies)

- Longitudes personalizadas disponibles para satisfacer los requisitos específicos de cada proyecto

- Longitudes aleatorias dobles y triples para soldadura de campo reducido

Esta amplia gama de productos posiciona a WUZHOU como proveedor integral para prácticamente cualquier aplicación de tuberías soldadas en espiral, desde la transmisión de petróleo y gas hasta la infraestructura hidráulica y el pilotaje estructural.

Garantía de calidad y certificaciones internacionales

El compromiso de WUZHOU’ con la calidad se valida mediante una certificación rigurosa y el cumplimiento de las normas internacionales:

- Certificación API 5L: Confirma el cumplimiento de las normas del Instituto Americano del Petróleo para tuberías

- Certificación ISO 9001: Valida el sistema de gestión de calidad de WUZHOU’

- Certificación ISO 14001: Demuestra su compromiso con la gestión medioambiental

- Cumplimiento de las normas de la UE: Garantiza la aceptabilidad de los proyectos de la Unión Europea

- Normas internacionales adicionales: Cumplimiento de diversas normas nacionales e internacionales

Estas certificaciones proporcionan a los compradores mayoristas una verificación independiente de la calidad de fabricación y el rendimiento de los productos de WUZHOU’. Para los proyectos internacionales que requieren un estricto cumplimiento de las normas específicas, las certificaciones integrales de WUZHOU’ eliminan las preocupaciones regulatorias y agilizan los procesos de aprobación.

Procesos avanzados de control de calidad

El control de calidad de WUZHOU’ supera las normas del sector:

- protocolo de inspección al 100: Todos los tubos en espiral se someten a pruebas exhaustivas

- Equipos avanzados de END: Tecnología punta en pruebas ultrasónicas, radiográficas y de otro tipo

- Laboratorio de pruebas propio: Instalaciones totalmente equipadas para pruebas mecánicas y físicas

- Documentación rigurosa: Registros de calidad exhaustivos desde la materia prima hasta el producto acabado

- Inspección por terceros: Verificación independiente disponible para requisitos especiales

Este compromiso inflexible con la calidad garantiza que los compradores mayoristas reciban productos que cumplan o superen los requisitos especificados. Para aplicaciones críticas en los sectores del petróleo, el gas, el agua y la energía, esta garantía de calidad se traduce directamente en una mayor fiabilidad de las infraestructuras y una reducción de los costes durante su vida útil.

Compromiso con la innovación y la mejora continua

WUZHOU mantiene su posición de liderazgo mediante una inversión continua en tecnología y mejora de procesos:

- Investigación y desarrollo: Avance continuo de las técnicas de fabricación

- Actualizaciones tecnológicas: Inversiones periódicas en equipos de última generación

- Optimización de procesos: Perfeccionamiento de los métodos de fabricación para mejorar la calidad y la eficacia

- Avance de la ciencia de los materiales: Desarrollo de formulaciones de acero y procedimientos de soldadura mejorados

- Iniciativas de sostenibilidad: Centrarse en la reducción del impacto medioambiental de las operaciones de fabricación

Para los compradores al por mayor, el enfoque innovador de WUZHOU’ ofrece beneficios tangibles en términos de rendimiento, fiabilidad y valor del producto. Sus tubos soldados en espiral incorporan los últimos avances en tecnología de fabricación, lo que resulta en productos superiores que satisfagan las demandas cambiantes de los proyectos de infraestructura modernos.

Aplicaciones e industrias de los tubos de acero soldados en espiral

Los tubos de acero soldados en espiral se han convertido en la columna vertebral de numerosas industrias por su versatilidad, resistencia y rentabilidad. Para los compradores mayoristas y los gestores de proyectos, comprender las diversas aplicaciones puede ayudar a identificar las especificaciones óptimas para sus requisitos específicos.

Infraestructuras de transporte de petróleo y gas

La industria del petróleo y el gas representa uno de los mayores mercados para los tubos de acero soldados en espiral, utilizándolos para:

Tuberías de transmisión:

- Redes transnacionales de transporte de petróleo y gas

- Sistemas de captación desde los campos de producción hasta las instalaciones de transformación

- Redes de distribución para el transporte de productos refinados

- Oleoductos para el transporte submarino de petróleo y gas

Instalaciones de la terminal:

- Sistemas de carga y descarga en terminales marítimas

- Sistemas de tuberías de las instalaciones de almacenamiento

- Conexiones de refinerías y plantas de transformación

Requisitos específicos de aplicación:

- Capacidad de servicio de alta presión

- Resistencia al servicio agrio (entornos H₂S)

- Recubrimientos y revestimientos resistentes a la corrosión

- Conexiones especializadas para aplicaciones submarinas

Los tubos soldados en espiral de WUZHOU’, fabricados según las normas API 5L, son idóneos para infraestructuras de transporte de petróleo y gas. Sus tubos de alta resistencia, disponibles en grados de hasta X80, proporcionan la resistencia a la presión y los márgenes de seguridad necesarios para estas aplicaciones críticas.

Gestión del agua e infraestructuras

El transporte y la gestión del agua representan otro importante sector de aplicación:

Sistemas municipales de abastecimiento de agua:

- Redes de transmisión desde los embalses a las instalaciones de tratamiento

- Redes de distribución para el abastecimiento urbano de agua

- Conducciones de agua potable

Sistemas de riego:

- Conducción de agua de gran diámetro para riego agrícola

- Cruces de canales y sifones

- Estructuras de entrada y salida del embalse

Aplicaciones hidroeléctricas:

- Llaves de paso para la producción de energía hidroeléctrica

- Tubos de tiro y túneles de desagüe

- Depósitos de compensación y ejes de presión

Aplicaciones costeras y marinas:

- Sistemas de entrada y salida de agua de mar

- Infraestructura de la planta desalinizadora

- Sistemas de agua de refrigeración para centrales eléctricas

WUZHOU suministra tubos soldados en espiral con revestimientos y recubrimientos adecuados para aplicaciones de infraestructuras de agua. Sus tuberías revestidas con mortero de cemento ofrecen una excelente resistencia a la corrosión y características de flujo para sistemas de agua potable, mientras que sus tuberías con revestimiento externo proporcionan protección a largo plazo para líneas de transmisión de agua enterradas.

Aplicaciones estructurales y de construcción

La industria de la construcción aprovecha los tubos soldados en espiral para diversas aplicaciones estructurales:

Sistemas de cimentación:

- Cimentaciones de pilotes de gran diámetro para puentes y edificios

- Pilotes marinos para estructuras portuarias

- Celdas circulares de tablestacas para ataguías y mamparos

Construcción de puentes:

- Cimentación de pilotes para pilas de puentes

- Elementos estructurales tubulares para superestructuras de puentes

- Túneles de servicio y conductos de servicios públicos

Sistemas de construcción:

- Columnas estructurales para edificios de gran altura

- Cimentación con pilotes para grandes estructuras

- Pozos de ventilación y conductos de servicios públicos

En la tabla siguiente se destacan los principales sectores y aplicaciones de los tubos de acero soldados en espiral:

| Industria | Aplicaciones | Requisitos clave | Solución de WUZHOU |

|---|---|---|---|

| Petróleo y gas | Tuberías de transmisión, sistemas de recogida | Alta presión nominal, conformidad con API | Tubos con certificación API 5L hasta el grado X80 con varias opciones de revestimiento |

| Infraestructuras hidráulicas | Abastecimiento municipal, sistemas de riego | Resistencia a la corrosión, potabilidad | Tuberías revestidas de mortero de cemento con revestimientos protectores externos |

| Construcción | Pilotes, elementos estructurales | Resistencia estructural, precisión dimensional | Tubos de pared gruesa con control dimensional preciso |

| Generación de energía | Tomas de agua, sistemas de refrigeración | Resistencia a la presión, larga vida útil | Tubos de alta resistencia con revestimientos especializados |

| Minería | Transporte de lodos, sistemas de deshidratación | Resistencia a la abrasión, durabilidad | Tuberías revestidas resistentes a la abrasión para una mayor vida útil |

| Industrial | Tuberías de proceso, sistemas de refrigeración | Resistencia química, fiabilidad | Diversas opciones de revestimiento para entornos químicos específicos |

Aplicaciones emergentes e innovaciones tecnológicas

La versatilidad de los tubos soldados en espiral sigue abriendo nuevas oportunidades de aplicación:

Captura y almacenamiento de carbono (CAC):

- Redes de transporte de CO₂ para el secuestro de carbono

- Infraestructura de pozos de inyección para almacenamiento subterráneo

- Sistemas de tuberías de las instalaciones de captura

Infraestructura del hidrógeno:

- Redes de transporte de hidrógeno para la distribución de energía limpia

- Conexiones de instalaciones de almacenamiento

- Sistemas industriales de suministro de hidrógeno

Sistemas de energía geotérmica:

- Revestimientos de pozos para producción geotérmica

- Transporte de vapor y agua caliente

- Infraestructuras de centrales eléctricas

Cimientos eólicos marinos:

- Cimentaciones monopilote para aerogeneradores

- Tubos en J y sistemas de protección de cables

- Cimentaciones de subestaciones marinas

WUZHOU se mantiene a la vanguardia de estas aplicaciones emergentes, adaptando continuamente sus capacidades de fabricación para satisfacer los requisitos cambiantes del mercado. Sus esfuerzos de investigación y desarrollo se centran en mejorar el rendimiento de las tuberías para estas nuevas aplicaciones, garantizando que sigan siendo un proveedor preferente para proyectos de infraestructuras innovadores.

Casos prácticos: Tuberías WUZHOU en acción

Gran proyecto de oleoducto en Asia Central:

- 320 km de tuberías soldadas en espiral de grado X70

- 1067 mm (42 pulgadas) de diámetro con 16 mm de grosor de pared

- revestimiento exterior de 3LPE para proteger contra la corrosión

- Terminado antes de lo previsto con cero rechazos de calidad

Proyecto municipal de abastecimiento de agua:

- 150 km de tuberías soldadas en espiral para el transporte urbano de agua

- 1800 mm de diámetro con revestimiento de mortero de cemento

- Revestimiento exterior de polietileno para proteger contra la corrosión

- Diseñada para una vida útil de 100 años

Fundación Puente Mayor:

- Pilotes en espiral de gran diámetro para puente sobre río

- 2200 mm de diámetro con 22 mm de grosor de pared

- Segmentos de longitud personalizada para condiciones geológicas específicas

- Instalación satisfactoria en lechos fluviales difíciles

Estos casos prácticos demuestran la capacidad de WUZHOU para suministrar tubos soldados en espiral de alta calidad para diversas aplicaciones en múltiples sectores. Su amplia capacidad de fabricación y su estricto control de calidad garantizan un rendimiento óptimo incluso en los entornos más exigentes.

Cómo elegir el fabricante de tubos espirales de acero adecuado para su empresa

Para los compradores mayoristas, distribuidores y jefes de proyecto, la selección del fabricante de tubos en espiral de acero adecuado es una decisión crítica que repercute en el éxito del proyecto, el rendimiento a largo plazo y el coste total de propiedad. Esta sección ofrece una guía esencial para evaluar y seleccionar proveedores de tubos en espiral.

Factores clave en la evaluación del fabricante

Al evaluar posibles fabricantes de tubos soldados en espiral, tenga en cuenta estos factores críticos:

Capacidad de fabricación:

- Capacidad de producción en relación con los requisitos de su proyecto

- Gama de dimensiones y especificaciones de tubos disponibles

- Antigüedad de los equipos de fabricación y sofisticación tecnológica

- Múltiples líneas de producción para mayor redundancia y flexibilidad

Sistemas de gestión de la calidad:

- Certificación ISO 9001 y otras certificaciones de calidad pertinentes

- Procedimientos de control de calidad y protocolos de ensayo documentados

- Capacidades y equipos de ensayo propios

- Historial de calidad e índices de defectos

Conocimientos técnicos y asistencia:

- Apoyo técnico para el desarrollo de especificaciones

- Asistencia técnica durante la ejecución del proyecto

- Capacidad de resolución de problemas para retos únicos

- Capacidades de I+D para requisitos especiales

Reputación y trayectoria en el sector:

- Resultados históricos en proyectos similares

- Referencias de clientes existentes

- Premios y reconocimientos del sector

- Longevidad y estabilidad en el mercado

WUZHOU sobresale en todas estas áreas críticas, con 13 líneas de producción avanzadas, certificaciones de calidad integrales, amplia experiencia técnica y un historial probado en diversas industrias. Su estatus como una de las 10 mejores marcas chinas de tubos de acero refleja su posición de liderazgo en la industria y su reputación de excelencia.

Coste total de propiedad

Aunque el precio inicial es importante, los compradores al por mayor deben evaluar el coste total de propiedad:

Costes relacionados con la calidad:

- Requisitos de inspección y ensayo

- Posibilidad de reparaciones o sustituciones sobre el terreno

- Fiabilidad de las prestaciones y riesgo de fallos

- Cobertura de la garantía y proceso de reclamación

Factores logísticos y de la cadena de suministro:

- Costes de transporte y complejidad logística

- Requisitos de gestión de existencias

- Fiabilidad de las entregas y cumplimiento de los plazos

- Embalaje y protección durante el transporte

Rendimiento del ciclo de vida:

- Vida útil prevista en función de la calidad de fabricación

- Requisitos de mantenimiento y costes asociados

- Resistencia a la corrosión y otros mecanismos de degradación

- Calendario y costes de la sustitución al final de la vida útil

Impacto de la ejecución del proyecto:

- Asistencia técnica durante la instalación

- Documentación y verificación del cumplimiento

- Capacidad de resolución de problemas

- Gestión y flexibilidad de las órdenes de cambio

El enfoque de WUZHOU’ en la fabricación de calidad y la asistencia integral al cliente ayuda a minimizar el coste total de propiedad. Aunque sus productos no siempre representan la opción de precio inicial más bajo, su calidad y fiabilidad superiores suelen traducirse en costes de vida útil más bajos y en una reducción del riesgo.

Lista de comprobación para la evaluación de proveedores

La siguiente lista de comprobación puede ayudar a los compradores al por mayor a evaluar sistemáticamente a los posibles fabricantes de tubos en espiral:

- Capacidad de fabricación

- La capacidad de producción cumple los requisitos del proyecto

- La tecnología de los equipos es actual y está bien mantenida

- Puede producir las especificaciones requeridas (diámetro, grosor de pared, grado)

- Ofrece las opciones de revestimiento y recubrimiento necesarias

- Garantía de calidad

- Posee las certificaciones de calidad pertinentes (ISO 9001, API, etc.)

- Realiza una inspección del 100% de los parámetros críticos

- Proporciona documentación exhaustiva sobre la calidad

- Tiene un historial de calidad demostrable

- Competencia técnica

- Personal de ingeniería con los conocimientos pertinentes

- Proporciona asistencia técnica y asesoramiento

- Demuestra que comprende los requisitos de la aplicación

- Tiene capacidad para resolver problemas únicos

- Gestión de la cadena de suministro

- Cumplimiento fiable de los plazos de entrega

- Programación transparente de la producción

- Sistemas de comunicación eficaces

- Respuesta flexible a las necesidades cambiantes

- Estabilidad empresarial

- Estabilidad financiera y longevidad

- Capacidad de producción suficiente para crecer

- Filosofía de mejora continua

- Inversión en tecnología e innovación

WUZHOU cumple o supera las expectativas en todas estas categorías de evaluación. Con 3 filiales, 2 fábricas, 4 bases de producción y 6 talleres de producción, ofrecen la escala de fabricación, el enfoque de calidad y la estabilidad empresarial que los compradores mayoristas requieren para los proyectos de infraestructuras críticas.

Establecer relaciones estratégicas con los proveedores

Para los compradores y distribuidores mayoristas, el desarrollo de relaciones estratégicas con fabricantes de calidad ofrece importantes ventajas:

Ventajas de la planificación colaborativa:

- Participación temprana en el desarrollo de las especificaciones del proyecto

- Aportaciones para la selección de materiales y el diseño de tuberías

- Optimización de la programación de la producción en consonancia con los plazos del proyecto

- Identificación y resolución proactiva de problemas

Trato preferente Ventajas:

- Programación prioritaria de la producción

- Acceso a recursos y conocimientos técnicos

- Respuesta más flexible a las necesidades cambiantes

- Condiciones comerciales potencialmente favorables

Oportunidades de transferencia de conocimientos:

- Formación y educación técnica

- Buenas prácticas específicas para cada aplicación

- Previsiones y tendencias del sector

- Nuevos productos y tecnologías

WUZHOU valora las relaciones a largo plazo con los compradores y distribuidores mayoristas, ofreciendo una gestión de cuentas dedicada, asesoramiento técnico y apoyo a la planificación colaborativa. Su enfoque centrado en el cliente garantiza que los socios reciban la atención y los recursos necesarios para la ejecución satisfactoria de los proyectos.

La ventaja WUZHOU para compradores al por mayor

WUZHOU ofrece a los compradores al por mayor varias ventajas convincentes en la compra de tubos de acero soldados en espiral:

- Excelencia en la fabricación: Con 11 líneas de producción de tubos en espiral y 2 líneas de revestimiento, WUZHOU ofrece una calidad constante y cumple los plazos más exigentes.

- Garantía global de calidad: el protocolo de inspección al 100%, que incluye pruebas de ultrasonidos, inspección por rayos X y pruebas de presión hidrostática, garantiza que todos los tubos cumplen las normas más estrictas.

- Certificación internacional: La certificación API 5L, ISO 9001, ISO 14001 y el cumplimiento de las normas de la UE proporcionan confianza en la aceptación global de los proyectos.

- Asistencia técnica: El asesoramiento de expertos en ingeniería ayuda a optimizar las especificaciones para aplicaciones y condiciones de funcionamiento específicas.

- Documentación completa: Los exhaustivos informes de materiales y calidad proporcionan una trazabilidad completa y la verificación de la conformidad.

Para los compradores al por mayor que buscan un proveedor fiable y de alta calidad de tubos soldados en espiral, WUZHOU representa una excelente opción con capacidades demostradas a través de diversas aplicaciones e industrias.

Preguntas frecuentes sobre la fabricación y suministro de tubos de acero soldados en espiral

Preguntas generales sobre fabricación

P: ¿Qué diferencia hay entre los tubos soldados en espiral y los tubos soldados longitudinalmente?

R: Los tubos soldados en espiral presentan una costura de soldadura helicoidal que gira en espiral alrededor de la circunferencia, mientras que los tubos soldados longitudinalmente tienen una costura recta que recorre toda su longitud. El proceso de fabricación en espiral permite un uso más eficiente del material, la producción de diámetros más grandes a partir de bobinas de acero más estrechas, y a menudo proporciona mejores características de distribución de la presión. Los tubos longitudinales ofrecen a veces una presión nominal ligeramente superior para el mismo grosor de pared, pero su diámetro máximo está limitado por la anchura disponible de las chapas.

P: ¿Cuáles son las limitaciones de longitud estándar de los tubos de acero soldados en espiral?

R: WUZHOU normalmente produce tubos soldados en espiral en longitudes estándar de 12 metros (aproximadamente 40 pies), aunque se pueden fabricar longitudes personalizadas para satisfacer los requisitos específicos del proyecto. La longitud máxima transportable suele estar limitada por las restricciones de transporte más que por las capacidades de fabricación. Para proyectos de mayor envergadura, WUZHOU puede fabricar tubos en longitudes de doble aleación o triple aleación para reducir el número de soldaduras de campo necesarias durante la instalación.

P: ¿Cómo afecta el grosor de la pared al rendimiento de los tubos soldados en espiral?

R: El grosor de la pared influye directamente en varias características de rendimiento de los tubos soldados en espiral:

- La presión nominal aumenta con el grosor de la pared

- La solidez estructural y la resistencia a las cargas externas mejoran con muros más gruesos

- Aumenta la resistencia al pandeo en condiciones de vacío

- Se mejoran las características de rigidez y maniobrabilidad durante la instalación

- La tolerancia a la corrosión y la vida útil pueden prolongarse

WUZHOU fabrica tubos soldados en espiral con espesores de pared que van de 5 mm a 25 mm, lo que permite la personalización en función de los requisitos específicos de rendimiento.

Cuestiones de calidad y pruebas

P: ¿Qué métodos de ensayo no destructivos se utilizan para garantizar la integridad de la soldadura en espiral?

R: WUZHOU emplea múltiples métodos de ensayo no destructivos para verificar la integridad de la soldadura:

- Pruebas ultrasónicas (UT): Los sistemas automatizados escanean el 100% de los cordones de soldadura para detectar defectos internos

- Pruebas radiográficas (RT): La inspección por rayos X revela defectos internos no visibles a simple vista

- Inspección por partículas magnéticas (MPI): Se utiliza para detectar defectos superficiales y cercanos a la superficie

- Pruebas de presión hidrostática: Verifica la integridad general de la tubería bajo presión

- Inspección visual: Inspectores formados examinan las soldaduras para detectar irregularidades superficiales

Estos métodos complementarios garantizan la detección exhaustiva de defectos y la verificación de la calidad.

P: ¿Cómo se determina la presión nominal de los tubos soldados en espiral?

R: Las presiones nominales de los tubos soldados en espiral se calculan en función de varios factores:

- Grado de acero límite elástico

- Espesor de la pared

- Diámetro del tubo

- Factores de seguridad especificados por los códigos aplicables

- Factores de eficacia de la unión para el método de soldadura

- Factores de reducción de temperatura para servicio a temperatura elevada

El cálculo básico sigue la fórmula de las normas aplicables, como ASME B31.3 o API 5L, con diversos factores de seguridad aplicados en función de la aplicación. WUZHOU proporciona información detallada sobre la presión nominal de todos sus tubos soldados en espiral basándose en estos cálculos estándar de la industria.

P: ¿Qué certificaciones de calidad debo buscar al comprar tubos soldados en espiral?

R: Las principales certificaciones que hay que buscar son las siguientes:

- API 5L: Esencial para aplicaciones de petróleo y gas

- ISO 9001: Verifica la aplicación del sistema de gestión de la calidad

- ISO 14001: Confirma las prácticas de gestión medioambiental

- Certificaciones específicas de productos: Como AWWA para aplicaciones de agua o conformidad NACE para servicios ácidos

WUZHOU cuenta con todas estas certificaciones críticas, lo que garantiza que sus tubos soldados en espiral cumplen las normas de calidad internacionales y los requisitos específicos de cada aplicación.

Preguntas sobre aplicaciones y especificaciones

P: ¿Cuáles son los diámetros máximo y mínimo disponibles para los tubos soldados en espiral?

R: WUZHOU fabrica tubos de acero soldados en espiral de diámetros comprendidos entre 219 mm (8 pulgadas) y 3500 mm (138 pulgadas). Esta amplia gama cubre la mayoría de las aplicaciones industriales, desde tuberías de extracción de petróleo y gas de tamaño moderado hasta grandes tuberías de transmisión de agua y pilotes estructurales. Se pueden fabricar diámetros a medida dentro de esta gama para satisfacer los requisitos específicos de cada proyecto.

P: ¿Qué sistemas de revestimiento se recomiendan para aplicaciones de tuberías enterradas?

R: Para aplicaciones de tuberías enterradas, WUZHOU recomienda:

- polietileno de 3 capas (3LPE): Proporciona una excelente protección contra la corrosión con resistencia a los daños mecánicos

- Epoxi unido por fusión (FBE): Ofrece buena resistencia química y estabilidad térmica

- Epoxi de alquitrán de hulla: Adecuado para condiciones de enterramiento húmedas y entornos marinos

- Polietileno extruido: Opción económica para condiciones menos exigentes

El sistema de revestimiento óptimo depende de las condiciones específicas del suelo, la temperatura de funcionamiento y los requisitos de servicio. El equipo técnico de WUZHOU’ puede ofrecer recomendaciones específicas para cada aplicación en función de los parámetros del proyecto.

P: ¿Cómo se comportan los tubos soldados en espiral en zonas sísmicas?

R: Los tubos soldados en espiral suelen presentar un buen comportamiento en zonas sísmicas debido a:

- El patrón de soldadura helicoidal, que puede proporcionar cierta flexibilidad durante el movimiento del suelo

- La capacidad de fabricar con aceros de mayor resistencia que combinan fuerza y ductilidad

- Opciones de conexiones especializadas diseñadas para aplicaciones sísmicas

Para aplicaciones críticas en regiones altamente sísmicas, WUZHOU puede suministrar tuberías con especificaciones mejoradas, incluidos grados de acero más altos con ductilidad mejorada y preparaciones finales personalizadas para conexiones sismorresistentes especializadas.

Preguntas sobre aprovisionamiento y logística

P: ¿Cuál es el plazo de entrega habitual para los pedidos de tubos soldados en espiral de gran diámetro?

R: Los plazos de entrega varían en función de varios factores:

- Cantidad del pedido y especificaciones

- Calendario de producción actual y utilización de la capacidad

- Disponibilidad de materias primas

- Requisitos de revestimiento

- Destino del envío y complejidad logística

Para las especificaciones estándar, WUZHOU suele ofrecer plazos de entrega de 4 a 8 semanas a partir de la confirmación del pedido. Los grandes proyectos pueden programarse con entregas escalonadas para adaptarse a las secuencias de construcción. Un compromiso temprano durante la fase de planificación permite una programación de la producción optimizada y unos plazos de entrega fiables.

P: ¿Qué documentación debe acompañar a las entregas de tubos soldados en espiral?

R: La documentación completa debe incluir:

- Informes de ensayo de materiales (MTR) para bobinas de acero

- Registros del proceso de fabricación

- Informes de inspección dimensional

- Resultados de ensayos no destructivos (informes UT, RT)

- Certificados de prueba hidrostática

- Informes de inspección de revestimientos

- Certificado de conformidad con las normas aplicables

- Documentación de trazabilidad que vincula los tubos a lotes de producción específicos

WUZHOU proporciona paquetes completos de documentación con todos los envíos, garantizando la trazabilidad completa y la verificación del cumplimiento.

P: ¿Cómo deben transportarse y almacenarse los tubos soldados en espiral para mantener la calidad?

R: Las mejores prácticas para el transporte y el almacenamiento incluyen:

- Uso de separadores de tuberías para evitar daños por contacto

- Tapones para proteger los biseles de los tubos y evitar la contaminación interna

- Material de estiba adecuado para evitar deformaciones durante el transporte

- Almacenamiento en terreno llano con apoyo adecuado

- Protección contra condiciones climáticas extremas para tuberías revestidas

- Segregación por tamaño, grado y especificación para la gestión de inventarios

- Inspección periódica durante los periodos de almacenamiento

WUZHOU proporciona directrices detalladas de manipulación y almacenamiento con sus envíos para garantizar el mantenimiento de la calidad de las tuberías a lo largo de toda la cadena logística y el período de almacenamiento in situ.

Preguntas de asistencia técnica

P: ¿Qué asistencia técnica ofrece WUZHOU durante la ejecución del proyecto?

R: WUZHOU proporciona asistencia técnica completa durante todo el ciclo de vida del proyecto:

- Asistencia en la elaboración de especificaciones durante la fase de diseño

- Asesoramiento en la selección de materiales en función de los requisitos de la aplicación

- Actualizaciones del progreso de fabricación durante la producción

- Documentación de calidad y verificación de la conformidad

- Asistencia técnica sobre el terreno para cuestiones de instalación

- Asistencia para la resolución de problemas si surgen durante la instalación

Su equipo técnico incluye ingenieros experimentados y familiarizados con diversas aplicaciones que pueden proporcionar valiosas ideas y recomendaciones para optimizar el rendimiento de las tuberías.

P: ¿Puede WUZHOU proporcionar soluciones personalizadas para requisitos de aplicación únicos?

R: Sí, WUZHOU ofrece capacidades de personalización que incluyen:

- Dimensiones o grosores de pared no estándar

- Aceros especiales para entornos extremos

- Preparaciones finales personalizadas para conexiones especializadas

- Combinaciones de revestimiento únicas para condiciones específicas

- Protocolos de prueba mejorados para aplicaciones críticas

- Sistemas especiales de marcado e identificación

Su equipo de ingenieros colabora estrechamente con los clientes para desarrollar soluciones a medida que respondan a los retos específicos de cada proyecto, cumpliendo al mismo tiempo las normas aplicables.

P: ¿Qué hay que tener en cuenta al elegir entre diferentes calidades de acero para tubos soldados en espiral?

R: Las consideraciones clave incluyen:

- Requisitos de presión de funcionamiento

- Condiciones de temperatura (tanto altas como bajas extremas)

- Elementos corrosivos en el medio transportado

- Condiciones ambientales externas

- Escenarios de carga mecánica

- Contenido de sulfuro de hidrógeno (H₂S) para aplicaciones de petróleo y gas

- Soldabilidad para la construcción sobre el terreno

- Consideraciones sobre costes y disponibilidad de material

El equipo técnico de WUZHOU’ puede proporcionar orientación detallada sobre la selección del grado en función de parámetros de aplicación específicos, ayudando a los compradores al por mayor a optimizar el equilibrio entre los requisitos de rendimiento y las consideraciones de coste.

Esta completa guía para la fabricación de tubos de acero soldados en espiral demuestra por qué WUZHOU se ha establecido como un fabricante líder en esta industria especializada. Con unas instalaciones de producción de última generación, un riguroso control de calidad y un compromiso con la satisfacción del cliente, WUZHOU suministra tubos soldados en espiral que cumplen las normas internacionales más exigentes.

Para los compradores al por mayor, distribuidores y jefes de proyecto que buscan tubos de acero soldados en espiral fiables y de alta calidad, WUZHOU ofrece la combinación perfecta de excelencia en la fabricación, diversidad de productos y asistencia técnica. Sus capacidades integrales -desde la selección de materias primas hasta el revestimiento y las pruebas, pasando por la producción- garantizan que los clientes reciban productos con un rendimiento fiable incluso en las aplicaciones más exigentes.

Póngase en contacto con WUZHOU hoy mismo para hablar de sus requisitos específicos de tuberías soldadas en espiral y descubra por qué se han convertido en el proveedor preferido para proyectos de infraestructuras críticas en todo el mundo.