مصدر أنابيب SSAW: الدليل النهائي لعام 2025

20 فبراير 20, 2025

شارك هذا المقال

مقدمة عن مصدري أنابيب SSAW

أن مصدر أنابيب SSAW (ملحومة بحرق حلزوني مغمور) يتخصص في توريد وتصدير أنابيب فولاذية كبيرة القطر وعالية القوة إلى الأسواق العالمية. تُستخدم هذه الأنابيب على نطاق واسع في خطوط أنابيب النفط والغاز، نقل المياه، الخوازيق، البناء، والتطبيقات الصناعية. مصدر أنابيب SSAW موثوق يضمن منتجات عالية الجودة، وتسعير تنافسي، والامتثال للمعايير الدولية مثل API 5L، وASTM A252، وGB/T9711.

لماذا تختار مصدر أنابيب SSAW موثوقًا؟

✔ منتجات معتمدة تتوافق مع المعايير العالمية

✔ خيارات توريد كبيرة بتسعير تنافسي

✔ تخصيص في القطر، وسمك الجدار، والطلاءات

✔ لوجستيات فعالة ودعم شحن عالمي

✔ تسليم في الوقت المحدد مع مساعدة في وثائق التصدير

يغطي هذا الدليل أفضل مصدري أنابيب SSAW في الصين، واتجاهات التسعير، ومقارنات الجودة، وكيفية اختيار المصدر المناسب لمشروعك.

أفضل مصدري أنابيب SSAW في الصين (2025)

الصين هي واحدة من أكبر مصدري أنابيب SSAW عالميًاتوفير أنابيب فولاذية عالية القوة ومقاومة للتآكل لمشاريع البنية التحتية والصناعية حول العالم.

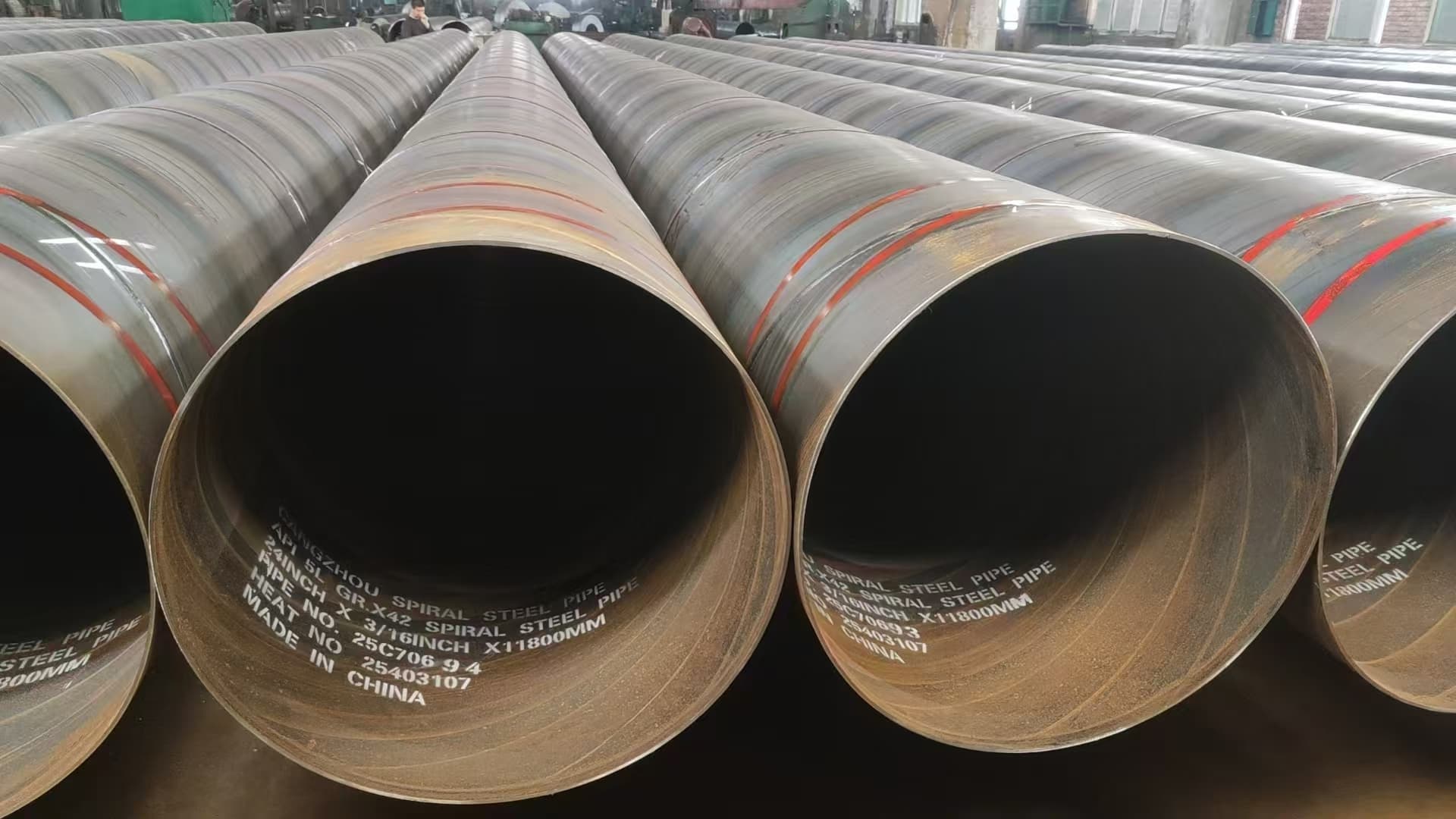

1. Cangzhou Spiral Steel Pipes Group Co., Ltd. (الأفضل للتصدير الكبير الحجم)

✔ أكثر من 27 عامًا من خبرة تصنيع وتصدير أنابيب SSAW

✔ 13 خط إنتاج لأنابيب SSAW (Φ219–Φ3500 مم)

✔ الطاقة الإنتاجية السنوية: 400,000 طن

✔ معتمدة بـ API 5L، ASTM A252، GB/T9711، ISO 9001

✔ تصدير إلى أكثر من 50 دولة حول العالم

📍 الموقع: رقم 92، طريق جييفانغ الشرقي، حي شينهوا، تشانغتشو، الصين

📞 الاتصال: طلب عرض أسعار

2. مجموعة أنابيب تيانجين يوفاس ستيل (الأفضل لتطبيقات الهياكل والخوازيق)

✔ واحدة من أكبر مصدري أنابيب SSAW في الصين

✔ يتخصص في أنابيب الخوازيق والتطبيقات الهيكلية

✔ تصدير إلى أكثر من 100 دولة حول العالم

📍 الموقع: تيانجين، الصين

📞 الاتصال: طلب عرض أسعار

3. شركة هينغيانغ فالين لأنابيب الفولاذ (الأفضل لخطوط أنابيب النفط والغاز)

✔ متخصصة في أنابيب SSAW المعتمدة من API 5L لمشاريع الطاقة

✔ اختبارات غير تدميرية (NDT) متقدمة ورقابة جودة

✔ أحجام وطلاءات مخصصة متوفرة

📍 الموقع: هينغيانغ، الصين

📞 الاتصال: طلب عرض أسعار

4. مجموعة باوستيل (الأفضل لأنابيب الصلب عالية القوة)

✔ أكبر مصنع صلب في الصين مع تصدير عالمي

✔ يوفر أنابيب SSAW عالية القوة للتطبيقات الثقيلة

✔ معتمدة بمعايير API 5L، CE، ISO 9001

📍 الموقع: شنغهاي، الصين

📞 الاتصال: طلب عرض أسعار

5. شركة مجموعة أنستيل (الأفضل للتطبيقات البحرية والبحرية النفطية)

✔ يتخصص في أنابيب SSAW مقاومة للتآكل للمشاريع البحرية النفطية

✔ يوفر طلاءات متقدمة مثل 3LPE، 3LPP، وإيبوكسي القطران الحجري

✔ يتوافق مع معايير API، ASTM، وDIN

📍 الموقع: أنشاان، الصين

📞 الاتصال: طلب عرض أسعار

يوفر كل مصدر أنابيب SSAW كبيرة الحجم بأسعار تصدير تنافسيةإرشادات CSA Z245.1 جودة عالية وتسليم في الوقت المناسب حول العالم.

مقارنة مصدري أنابيب SSAW: الاختلافات الرئيسية

| مصدر | تتبع عملية دقيقة لضمان | الشهادات | الطاقة الإنتاجية | التخصيص |

|---|---|---|---|---|

| مجموعة كانغتشو للأنابيب الفولاذية الحلزونية | مشاريع صناعية كبيرة الحجم | API 5L، ASTM A252، GB/T9711، ISO 9001 | 400,000 طن/سنة | نعم، أحجام وطلاءات مخصصة |

| مجموعة تيانجين يوفا لأنابيب الصلب | تطبيقات هيكلية وخوازيق | API 5L، ISO 9001، ASTM | 300,000 طن/سنة | نعم، خيارات محدودة |

| شركة هنغيانغ فالين لأنابيب الصلب | مواصفات CSA Z245.1 | API 5L، ASTM، GB/T | 250,000 طن/سنة | نعم، لأنابيب الضغط العالي |

| مجموعة باوستيل | أنابيب صلب عالية القوة | API 5L، CE، ISO 9001 | 350,000 طن/سنة | نعم، درجات صلب متقدمة |

| شركة مجموعة أنستيل | تطبيقات بحرية وبحرية نفطية | API، ASTM، DIN | 200,000 طن/سنة | نعم، طلاءات مقاومة للتآكل |

اتجاهات أسعار تصدير أنابيب SSAW في 2025

سعر أنابيب SSAW المصدرة يعتمد على عوامل مثل درجة الصلب، وقطر الأنبوب، وسمك الجدار، ونوع الطلاء. فيما يلي تقديرات سعر التصدير للطن لعام 2025:

| سُمك الجدار (مم) | درجة الفولاذ | سعر التصدير للطن (دولار أمريكي) |

|---|---|---|

| 6 - 10 مم | api 5l x42 - x65 | 600−600 – 600−900 |

| 12 - 18 مم | api 5l x65 - x70 | 850−850 – 850−1,200 |

| 20 - 40 مم | api 5l x70 - x80 | 1,100−1,100 – 1,100−1,500 |

العوامل المؤثرة في تسعير تصدير أنابيب SSAW

✔ درجة الفولاذ: درجات القوة الأعلى (X70، X80) أغلى تكلفة.

✔ نوع الطلاء: طلاءات 3LPE، 3LPP، وFBE تزيد التكلفة.

✔ خصومات الطلبات الكبيرة: الطلبات الأكبر تتأهل لـ أسعار أقل للطن.

✔ الشحن واللوجستيات: تختلف الأسعار حسب تكاليف الشحن والوجهة.

تقدم مجموعة أنابيب الصلب الحلزونية الحلزونية من تشانجتشو تسعير تصدير تنافسي للطلبات الكبيرة على أنابيب SSAW.

كيفية استيراد أنابيب SSAW من الصين؟

عملية الاستيراد خطوة بخطوة

✔ الخطوة 1: اختر مصدرًا موثوقًا

- تحقق شهادات API و ASTM و ISO

- الطلب عينات المنتج وفحص المصنع

✔ الخطوة 2: طلب عرض أسعار تصدير

- توفير مواصفات الأنابيب (القطر، السماكة، درجة الفولاذ، نوع الطلاء)

- احصل على أسعار شروط FOB أو CIF أو EXW

✔ الخطوة 3: إنهاء الطلب وشروط الدفع

- التفاوض على خصومات الشراء بالجملة و خيارات الدفع (T/T، L/C، إلخ)

- تأكيد أوقات الإنتاج وجدول التسليم

✔ الخطوة 4: فحص الجودة والاختبار

- قم بالترتيب ل فحص الطرف الثالث (SGS، BV، إلخ)

- ضمان الامتثال لـ مواصفات العقد

✔ الخطوة 5: الشحن والتخليص الجمركي

- العمل مع وكلاء الشحن للخدمات اللوجستية السلسة

- تقديم ما يلزم المستندات الجمركية (بوليصة الشحن، قائمة التعبئة، الفاتورة التجارية، إلخ)

الإيبوكسي المركّب بالاندماج (FBE)، 3LPE، وبطانة الملاط الإسمنتي خدمات تصدير سلسة لطلبات أنابيب SSAW بالجملة عالميًا.

عملية تصنيع أنابيب SSAW وضبط الجودة

كيف يتم تصنيع أنابيب SSAW؟

إن عملية تصنيع أنابيب SSAW (اللحام بالقوس المغمور حلزونيًا) تشمل خطوات متعددة لضمان القوة والمتانة والامتثال للمعايير الدولية. فيما يلي تفصيل لـ عملية تصنيع أنابيب SSAW:

1️⃣ اختيار المواد الخام

- عالية الجودة لفائف الصلب يتم اختيارها بناءً على معايير API 5L و ASTM A252 و GB/T9711.

- الفولاذ درجات مثل X42، X52، X65، وX80 تُستخدم عادةً.

2️⃣ التشكيل الحلزوني

- يتم فك لفائف الصلب وتسطيحها قبل إدخالها إلى آلة التشكيل.

- الحواف هي محاذاتها لتشكيل شكل حلزوني، مما يضمن خيط لحام مستمر ومنتظم.

3️⃣ اللحام بالقوس المغمور (SAW)

- اللحام الداخلي والخارجي يتم باستخدام تقنية اللحام بالقوس المغمور (SAW).

- توفر هذه الطريقة اختراقًا عميقًا ونزاهة لحام قوية.

4️⃣ الاختبار بالموجات فوق الصوتية والأشعة السينية

- الاختبارات غير المتلفة (NDT) يُجرى لاكتشاف عيوب اللحام وعدم التوافق.

- الاختبار بالموجات فوق الصوتية والأشعة السينية يضمن خيوط لحام خالية من العيوب.

5️⃣ الاختبار الهيدروستاتيكي

- تُختبر أنابيب SSAW تحت ظروف ماء عالي الضغط لضمان قدرتها على تحمل ضغط شديد.

6️⃣ فحص الأبعاد

- قطر الأنبوب، سمك الجدار، والطول يُفحص الامتثال لـ مواصفات العميل.

7️⃣ هل تحتاج أنابيب CSA Z245.1 إلى طلاء؟

- الأنابيب مطلية بما يلي FBE، 3LPE، 3LPP، أو طبقات واقية أخرى لمنع الصدأ والتآكل.

8️⃣ الفحص النهائي والعلامة

- يُجرى فحص جودة نهائي لضمان الامتثال الكامل لمعايير API 5L، ASTM A252، وغيرها.

- يتم تمييز الأنابيب بـ أرقام الدفعات، المواصفات، وتفاصيل الشركة المصنعة.

إجراءات مراقبة الجودة لأنابيب SSAW

| نوع الاختبار | الغرض | طرق الاختبار |

|---|---|---|

| الاختبار بالموجات فوق الصوتية (UT) | يكتشف العيوب الداخلية | يستخدم الموجات فوق الصوتية لفحص الشقوق والفراغات |

| الاختبار بالأشعة السينية (RT) | يضمن نزاهة خيط اللحام | مسح الأشعة السينية للمفاصل الملحومة |

| اختبار الضغط الهيدروستاتيكي | يفحص قوة الأنبوب تحت الضغط | تملأ الأنابيب بالماء وتُختبر عند 1.5 ضعف الضغط التصميمي |

| اختبار التأثير | يختبر الصلابة في درجات حرارة منخفضة | تعرض الأنابيب لقوى صدمة مفاجئة |

| تحليل التركيب الكيميائي | يضمن جودة المادة | تحليل مطيافي لتركيب الصلب |

| فحص الأبعاد | يفحص قطر الأنبوب والسمك والطول | أدوات قياس دقيقة تُستخدم للدقة |

تلتزم مجموعة أنابيب الصلب الحلزوني في تشانغتشو بـ تدابير صارمة لمراقبة الجودة لضمان منتجات خالية من العيوب بنسبة 100%.

تغليف ولوجستيات تصدير أنابيب SSAW

كيف تُحزم أنابيب SSAW للتصدير؟

لضمان نقل آمن وتسليم، تُخضع أنابيب SSAW لـ تغليف ومعالجة مناسبة قبل الشحن.

✔ حزم بأشرطة فولاذية – يضمن ترتيبًا آمنًا ويمنع الحركة أثناء النقل.

✔ غطاء نهاية بلاستيكي – يحمي نهايات الأنبوب من التلف والتلوث.

✔ تغليف مقاوم للماء – يمنع تلف الرطوبة والصدأ.

✔ نقش وعلامة مخصصة – تُعلم الأنابيب بـ المواصفات، أرقام الدفعات، وتفاصيل التصدير.

✔ صناديق خشبية (للأنابيب الصغيرة) – يضمن معالجة آمنة لأنابيب قطر صغير.

الشحن واللوجستيات لتصدير أنابيب SSAW

✔ FOB (مجاني على متن السفينة) – يسلم المصدر الأنابيب إلى الميناء، ويتولى المشتري الشحن.

✔ CIF (التكلفة والتأمين والشحن) – يرتب المصدر الشحن والتأمين إلى وجهة المشتري.

✔ DDP (تسليم مدفوع الرسوم) – يتولى المصدر جميع إجراءات الجمارك والنقل إلى موقع المشتري.

الإيبوكسي المركّب بالاندماج (FBE)، 3LPE، وبطانة الملاط الإسمنتي لوجستيات فعالة وشحن عالمي لضمان تسليم في الوقت المحدد.

تطبيقات أنابيب SSAW عبر الصناعات

أين تُستخدم أنابيب SSAW؟

✔ خطوط أنابيب النفط والغاز – تُستخدم لـ نقل طويل المدى للنفط الخام والغاز الطبيعي ومنتجات البترول.

✔ خطوط نقل المياه – مثالية لـ إمدادات المياه البلدية والري ومشاريع التحلية.

✔ التطبيقات الهيكلية والدعامات – توفر دعم أساس قوي للجسور والمباني والطرق السريعة.

✔ مشاريع الحفر البحري والبحرية – تُستخدم في الحفر البحري وإنشاء الموانئ وبناء السفن.

✔ توليد الطاقة والاستخدام الصناعي – مناسبة لـ محطات الطاقة الحرارية والمصافي والصناعات الكيميائية.

مجموعة كانجتشو للأنابيب الفولاذية الحلزونية تورد أنابيب SSAW عالية الجودة لـ مشاريع البنية التحتية العالمية.

كيفية اختيار أفضل مصدر أنابيب SSAW؟

العوامل الرئيسية التي يجب مراعاتها

✔ الشهادات والامتثال – تأكد من امتثال المصدر لـ معايير API 5L، ASTM A252، GB/T9711، وISO 9001.

✔ القدرة الإنتاجية والموثوقية – اختر مصدرًا بـ قدرات تصنيع واسعة النطاق.

✔ التخصيص وخيارات الطلاء – تأكد من توفيرهم أقطار مخصصة، سمك جدران، وطلاءات (FBE، 3LPE، 3LPP، إلخ).

✔ تسعير تنافسي وشروط دفع – قارن الأسعار من مصدرين متعددين لضمان أفضل صفقة.

✔ دعم اللوجستيات والشحن – تحقق مما إذا كان المصدر يوفر خدمات التسليم من الباب إلى الباب ووثائق التصدير.

مجموعة أنابيب الفولاذ الحلزوني في تشانغتشو هي مصدر موثوق لأنابيب SSAWتقدم توريد بالجملة وحلول مخصصة للمشترين الدوليين.

أسئلة شائعة: مصدري أنابيب SSAW والتجارة الدولية

| سؤال | الإجابة |

|---|---|

| من هو أفضل مصدر لأنابيب SSAW في الصين؟ | شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة مصدر رائد بـ قدرات توريد بالجملة وتسعير تنافسي. |

| أي الصناعات تستخدم أنابيب SSAW؟ | النفط والغاز، نقل المياه، البناء، الخوازيق، والتطبيقات الصناعية. |

| هل يمكن طلاء أنابيب SSAW مخصصًا؟ | نعم، يقدم المصدرون طلاءات مثل 3LPE، 3LPP، FBE، وإيبوكسي القطران الحجري. |

| كم يستغرق شحن الطلبات الدولية؟ | وقت الإنتاج يختلف (عادة 15-45 يومًا)، مع خيارات شحن عالمية. |

| ما هي الكمية الدنيا للطلب (MOQ) لمشتريات التصدير؟ | يعتمد موك على المورد، ولكن الطلبات بالجملة (أكثر من 50 طن) تحصل على أسعار أفضل. |

| كيف تُحزم أنابيب SSAW للتصدير؟ | تُحزم الأنابيب وتُغطى وتُغلف بمواد مقاومة للماء وتُعلم بالمواصفات. |

| ما هي شروط الدفع الشائعة لمصدري أنابيب SSAW؟ | يشيع استخدام T/T (حوالة برقية) وL/C (خطاب اعتماد) وD/P (مستندات مقابل الدفع). |

الأفكار النهائية

بالنسبة لـ أنابيب SSAW عالية الجودة للتصدير, شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة هو الشريك الأفضل في 2025!

✔ أكثر من 27 عاماً من الخبرة

✔ 400,000 طن من الطاقة الإنتاجية السنوية

✔ معتمدة بمعايير API 5L، ASTM، GB/T، ISO 9001

✔ أحجام مخصصة، طلاءات، وشحن عالمي

📞 هل تحتاج عرض أسعار تصدير؟ اتصل بنا مجموعة أنابيب الصلب الحلزونية الحلزونية في تشانغتشو اليوم!