الجهة المصنعة للأنابيب الملحومة الحلزونية CSA Z245.1

توافر المخزون مخزون كبير جاهز للشحن الفوري.

ضمان الجودة

يخضع كل أنبوب لاختبارات صارمة، بما في ذلك الفحص بالموجات فوق الصوتية والاختبار الهيدروستاتيكي والفحص التلفزيوني الصناعي، مما يضمن الامتثال لشهادات API 5L وشهادات الاتحاد الأوروبي.

خدمة OEM & ODM

نحن نقدم حلولاً قابلة للتخصيص بالكامل، بدءاً من اختيار المواد إلى الطلاءات والأبعاد المتخصصة، مما يلبي احتياجات الصناعة المتنوعة.

التوصيل في الوقت المحدد

من خلال 13 خط إنتاج، و4 خطوط مضادة للتآكل، وقواعد تصنيع متعددة، نضمن كفاءة الإنتاج والتسليم في الوقت المناسب للأسواق العالمية.

شارك هذا المنتج

الحل الشامل

بدءاً من التصميم وحتى الإنتاج، نقدم حلولاً مخصصة للأنابيب الفولاذية الحلزونية، بما في ذلك الطلاءات المضادة للتآكل وضمان الجودة.

نطاق واسع الحجم

تتراوح أنابيبنا من Φ219 مم إلى Φ3500 مم، مع خيارات متنوعة لسُمك الجدار، بما يلبي متطلبات المشاريع المتنوعة.

المعايير الدولية

منتجاتنا معتمدة وفقًا لمعايير API 5L وSY/T وGB/T، وهي تلبي لوائح الصناعة العالمية من حيث الموثوقية والمتانة.

نظرة عامة على أنبوب اللحام الحلزوني CSA Z245.1

عند الحديث عن خطوط الأنابيب عالية القوة للتطبيقات الحرجة، أنبوب اللحام الحلزوني CSA Z245.1 هو الخيار الأول. هذا معيار الأنابيب، الذي أقرته الجمعية الكندية للمعايير (CSA)، يضمن أن أنابيب الصلب الملحومة حلزونيًا تلبي المتطلبات الميكانيكية والكيميائية والأدائية الصارمة لـ النفط والغاز، نقل المياه، والبنية التحتية الصناعية.

بخلاف الأنابيب السلسة أو ERW (اللحام بالمقاومة الكهربائية), الأنابيب الملحومة الحلزونية العرض قوة أعلى، ومعالجة ضغط أفضل، وكفاءة تكلفة، مما يجعلها خيارًا مفضلاً لمشاريع الأقطار الكبيرة.

في هذا الدليل، سنتعمق في أنبوب اللحام الحلزوني CSA Z245.1, تغطي المصنعين، واتجاهات الأسعار، والمواصفات، والتطبيقات، والطلاءات، وعمليات اللحام.

أفضل مصنعي أنابيب اللحام الحلزوني CSA Z245.1

عند اختيار مصنّع أنابيب ملحومة حلزونيًا CSA Z245.1، فإن الجودة والموثوقية والامتثال للمعايير الدولية أمر حاسم. إليك بعض الشركات المصنّعة الرائدة:

1. Cangzhou Spiral Steel Pipes Group Co., Ltd.

✔ 27 عاماً من الخبرة في تصنيع أنابيب الصلب

✔ 13 خط إنتاج لـ Φ219-Φ3500 مم الأنابيب الملحومة الحلزونية

✔ معتمدة من ISO9001 و API Spec 5L و CSA Z245.1

✔ الطاقة الإنتاجية السنوية: 400,000 طن

✔ الطلاء المخصص متاح: FBE، 3LPE، تبطين الملاط الأسمنتي

2. Evraz North America

مصنّع كندي رائد متخصص في أنابيب معتمدة CSA Z245.1 لخطوط أنابيب النفط والغاز.

3. Tenaris

مصنّع عالمي لأنابيب الصلب يوفر أنابيب ملحومة حلزونيًا عالية الجودة لمشاريع الطاقة والبنية التحتية.

4. Jindal SAW Ltd

أحد أكبر مصدّري الأنابيب الملحومة الحلزونية إلى أمريكا الشمالية، متوافقة مع معايير CSA Z245.1.

5. Tianjin Steel Pipe Corporation

مصنّع صيني متخصص في أنابيب كبيرة القطر عالية القوة الفولاذ للمشاريع الصناعية. التزام صارم بمعايير CSA Z245.1

يضمن كل من هذه الشركات المصنعة القوة والمتانة ومقاومة التآكلضماناً لـ أنابيب ملحومة حلزونيًا CSA Z245.1 مقابل أنواع الأنابيب الأخرى.

فهم الاختلافات بين

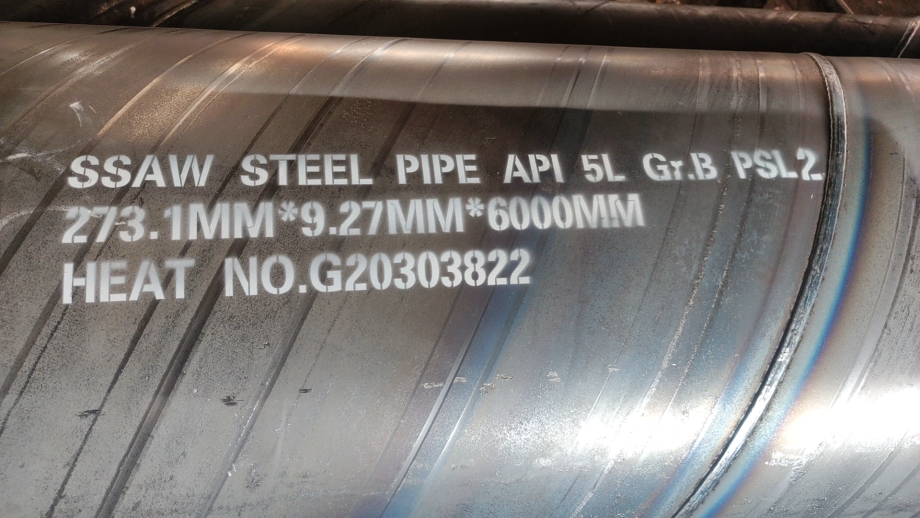

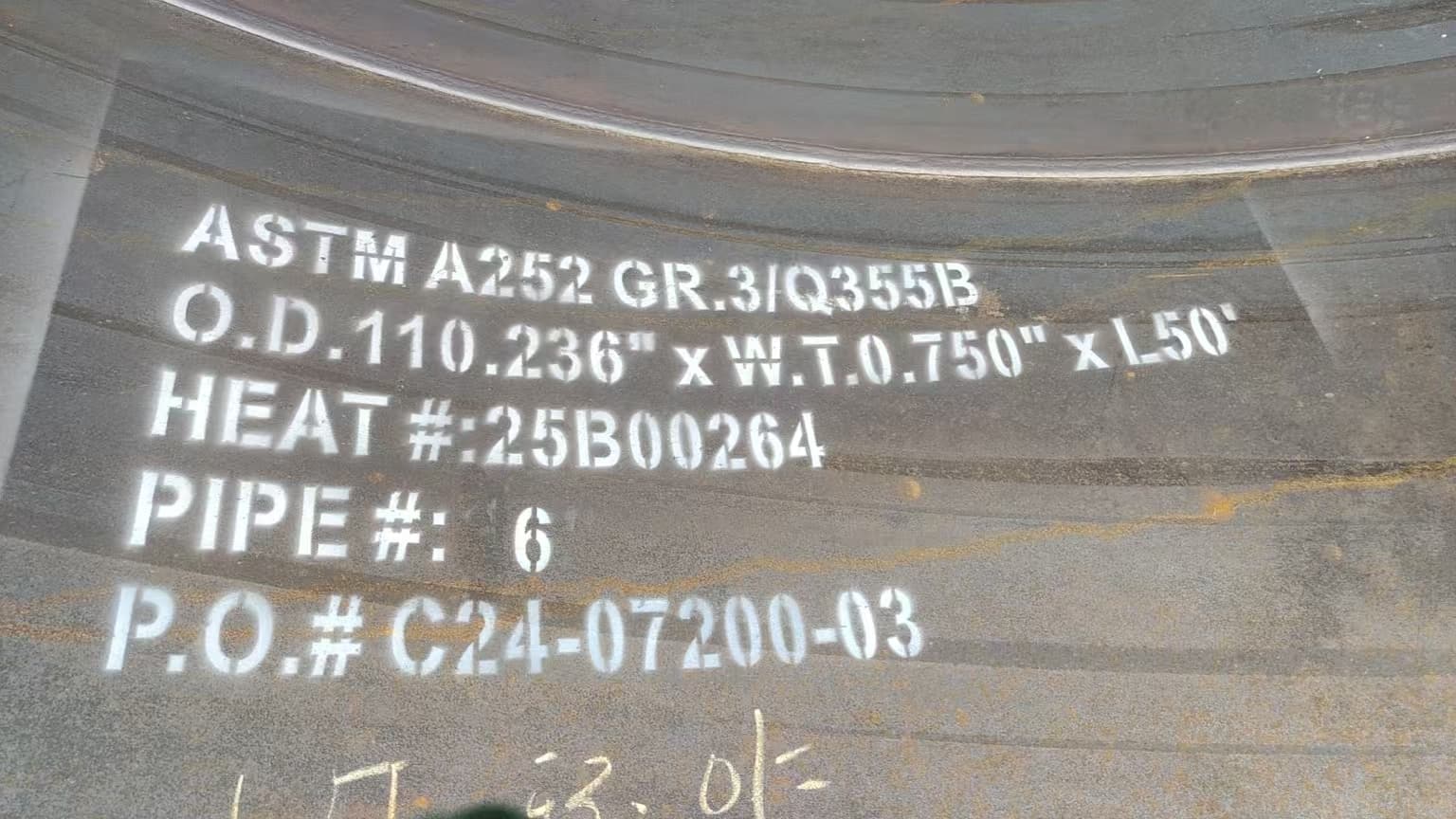

أنابيب ملحومة حلزونيًا CSA Z245.1 وأنواع الأنابيب الأخرى أمر حاسم لاختيار المنتج المناسب لمشروعك. لحام قوس مغمور حلزوني (SSAW)

| الميزة | أنبوب اللحام الحلزوني CSA Z245.1 | لحام عالي التردد | أنابيب الصلب غير الملحومة |

|---|---|---|---|

| عملية التصنيع | بدون لحام (مبثوقة من صلب صلب) | كبير (حتى 3500 مم) | لماذا تختار أنابيب ملحومة حلزونيًا CSA Z245.1؟ |

| مثالية للنفط والغاز ونقل المياه والتطبيقات الصناعية | مرتفعة بسبب الخياطة الحلزونية | معتدل | عالية جداً |

| مقاومة الضغط | ممتاز | معتدل | متفوقة |

| مقاومة التآكل | يمكن تحسينه بالطلاء | يتطلب طلاءً إضافيًا | أكثر مقاومة طبيعيًا |

| التكلفة | سعر طن أنابيب ملحومة حلزونيًا CSA Z245.1 في عام 2025 | أعلى قليلاً | باهظة الثمن |

| نطاق القطر | يتقلب بناءً على عوامل مثل | المواد الخام والقطر والطلاءات والطلب العالمي | المواد الخام والقطر والطلاءات والطلب العالمي |

| . إليك جدول تسعير تقديري لعام 2025: | خطوط أنابيب النفط والغاز والمياه، والمشاريع الهيكلية | نقل المياه والبناء والتشييد | تطبيقات الضغط العالي |

– تقلبات المواد الخام تؤثر على التكاليف.

✔ تكاليف التصنيع

✔ – تكاليف العمالة والطاقة والنقل.

✔ أسهل في التصنيع بأطوال طويلة

✔ الطلاءات ومعالجات مكافحة التآكل

– الطلاءات المخصصة تزيد من الأسعار.

سعر وأنواع الأنابيب الأخرى أمر حاسم لاختيار المنتج المناسب لمشروعك. – الطلبيات الكبيرة تحصل عادةً على أسعار مخفضةمواصفات ومعايير أنابيب ملحومة حلزونيًا CSA Z245.1

| قطر الأنبوب (مم) | سُمك الجدار (مم) | سعر الطن (بالدولار الأمريكي) |

|---|---|---|

| 219 – 600 | 6 – 10 | 850−850 – 850−1,250 |

| 610 – 1200 | 8 – 14 | 1,150−1,150 – 1,150−1,600 |

| 1220 – 1800 | 10 – 16 | 1,350-1,350 - 1,350-1,900 |

| 2000 – 3500 | 12 – 25 | 1,700−1,700 – 1,700−2,600 |

العوامل المؤثرة في السعر:

✔ متطلبات CSA Z245.1 CSA Z245.1:2025

✔ طلاء أنابيب ملحومة حلزونيًا CSA Z245.1 ومعالجات مكافحة التآكل لتعزيز المتانة،

✔ تخضع لمعالجات طلاء وحماية من التآكل متنوعة

✔ الفوائد مقاومة عالية للتآكل، سطح أملس مقاومة عالية للصدمات، حماية من الرطوبة.

تقدم مجموعة أنابيب الصلب الحلزونية الحلزونية من تشانجتشو تسعير تنافسي وخصومات على الكميات الكبيرة لـ وأنواع الأنابيب الأخرى أمر حاسم لاختيار المنتج المناسب لمشروعك..

خطوط الأنابيب تحت الأرض

لتلبية يمنع التآكل الداخلي، يحسّن جودة المياه، يجب أن تلتزم أنابيب اللحام الحلزوني بمواصفات صارمة.

| المواصفات | التفاصيل |

|---|---|

| قياسي | خطوط نقل المياه |

| نطاق القطر | 219 مم - 3500 مم |

| سُمك الجدار | 6 مم - 25 مم |

| المواد | صلب الكربون (GR B، X42-X80) |

| عملية التصنيع | اللحام بالقوس المغمور (SAW) |

| طرق الاختبار | فحص بالموجات فوق الصوتية، وهيدروستاتيكي، وأشعة إكس |

| خيارات الطلاء | FBE، 3LPE، بطانة أسمنتية |

تضمن هذه المواصفات وأنواع الأنابيب الأخرى أمر حاسم لاختيار المنتج المناسب لمشروعك. أن تكون قوية ومتينة ومقاومة للتآكل، مما يجعلها مثالية للنفط والغاز ونقل المياه.

اقتصادي، يحمي من تآكل التربة

التنجين وأنواع الأنابيب الأخرى أمر حاسم لاختيار المنتج المناسب لمشروعك. مقاومة الصدأ، عمر افتراضي طويل أقصى طول عمر.

| عملية لحام وتصنيع أنابيب ملحومة حلزونيًا CSA Z245.1 | كيف يتم تصنيع أنابيب ملحومة حلزونيًا CSA Z245.1؟ | تتبع عملية دقيقة لضمان |

|---|---|---|

| . إليك تفصيلًا لكيفية إنتاج هذه الأنابيب: | يتم اختيار صلب كربون عالي الجودة بناءً على | مواصفات CSA Z245.1 |

| تشمل المواد الشائعة | يتم إدخال شريط الصلب إلى آلة تشكيل، حيث يتم لفّه باستمرار إلى | شكل حلزوني |

| يتم تشكيل اللحام، مما يعزز مقاومة الضغط. | يتم تطبيق | لضمان الاختراق العميق واللحامات القوية. |

| تعزز هذه العملية | فحص بالموجات فوق الصوتية والأشعة السينية | اختبار غير تدميري (NDT) |

| يضمن أن الأنابيب قادرة على تحمل الضغوط الداخلية. | الطلاء ومعالجة مكافحة التآكل | اعتمادًا على التطبيق، يتم تطبيق طلاءات مثل |

الإيبوكسي المركّب بالاندماج (FBE)، 3LPE، وبطانة الملاط الإسمنتي . يتم ختم الأنابيب وشهادتها وفقًا لـ لـ أنابيب معتمدة CSA Z245.1إرشادات CSA Z245.1 تقنيات اللحام المستخدمة في أنابيب حلزونية CSA Z245.1.

اختراق عميق، لحامات قوية، كفاءة عالية

تستخدم مجموعة Cangzhou Spiral Steel Pipes Co., Ltd

تقنيات لحام واختبار حديثة وأنواع الأنابيب الأخرى أمر حاسم لاختيار المنتج المناسب لمشروعك. لضمان أنابيب ملحومة حلزونيًا CSA Z245.1 عالية الجودةموردو ومصدري أنابيب ملحومة حلزونيًا CSA Z245.1

- اختيار لفائف الصلب

- إذا كنت تخطط لـ استيراد أنابيب ملحومة حلزونيًا CSA Z245.1.

- ، فاختر GR B، X42، X52، X60، X70، وX80.

- عملية التشكيل الحلزوني

- سعة إنتاج عالية، تسعير تنافسي، وتقنيات تصنيع متقدمة أفضل مصدّري الصين لأنابيب ملحومة حلزونيًا CSA Z245.1.

- إن درز حلزوني لماذا تختار مجموعة Cangzhou Spiral Steel Pipes لأنابيب حلزونية CSA Z245.1؟

- اللحام بالقوس المغمور (SAW)

- اللحام بالقوس المغمور على الوجهين (DSAW) معتمدة CSA Z245.1 و API و ISO

- 13 خط إنتاج، تغطي أقطار الأنابيب من 219 مم إلى 3500 مم شبكة تصدير قوية إلى أمريكا الشمالية وأوروبا والشرق الأوسط.

- إذا كنت تبحث عن

- مورد موثوق لأنابيب ملحومة حلزونيًا CSA Z245.1 أسئلة شائعة: أنابيب ملحومة حلزونيًا CSA Z245.1 ما هي استخدامات أنابيب ملحومة حلزونيًا CSA Z245.1؟

- CSA Z245.1 مثالية للمشاريع الكندية والأمريكية الشمالية، بينما يُستخدم API 5L عالميًا شهادات ISO و CSA Z245.1

- هل تحتاج أنابيب CSA Z245.1 إلى طلاء؟

- قوة عالية، فعالية من حيث التكلفة، ومتانة ، مما يجعلها مثالية لـ نقل النفط والغاز، خطوط الأنابيب المائية، والتطبيقات الهيكلية

- الفحص النهائي والاعتماد

- يتم اختبار كل أنبوب من أجل دقة الأبعاد والخصائص الميكانيكية وجودة الطلاء.

- مصنّع أنابيب ملحومة حلزونيًا JIS 3457 - Cangluo أنابيب ملحومة حلزونيًا JIS 3457 هي معيار أنابيب صلب يحكمه المعايير الصناعية اليابانية (JIS)، وتحديدًا JIS G 3457، والتي تُستخدم على نطاق واسع لنقل المياه.

نظرة عامة على أنابيب ملحومة حلزونيًا JIS 3457

| طريقة اللحام | المزايا |

|---|---|

| اللحام بالقوس المغمور (SAW) | أنابيب ملحومة حلزونيًا JIS 3457 |

| اللحام على الوجهين (DSAW) | يضمن قوة موحدة ويمنع نقاط الضعف |

| الاختبار الهيدروستاتيكي | التحقق من مقاومة الضغط، وضمان عدم وجود تسربات |

هي معيار أنابيب صلب يحكمه المعايير الصناعية اليابانية (JIS)، وتحديدًا JIS G 3457 ، والتي تُستخدم على نطاق واسع لـ نقل المياه، التطبيقات الهيكلية، وخطوط الأنابيب الصناعية.

. تُعرف هذه الأنابيب بـ

أنظمة إمداد المياه بعيدة المدى، الجسور، ومشاريع البنية التحتية الأخرى أنابيب سلسة أو ERWأقطار أكبر، مقاومة ضغط أفضل، وتكاليف إنتاج أقل مصدّر موثوق به ، مما يجعلها الخيار المفضل لـ مصدّر رائد في مجال التصدير بسبب التطبيقات الصناعية والهيكلية واسعة النطاق.

أفضل مصنّعي أنابيب ملحومة حلزونيًا JIS 3457

| اسم الشركة | الموقع | الطاقة الإنتاجية السنوية |

|---|---|---|

| شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة | خبي، الصين | 400,000 طن |

| مجموعة باوستيل | شنغهاي، الصين | أكثر من 500,000 طن |

| شركة تيانجين لأنابيب الصلب | تيانجين، الصين | 300,000 طن |

معايير JIS 3457

✔ 27 عاماً من الخبرة في تصنيع الأنابيب الفولاذية

✔ . فيما يلي

✔ بعض الشركات المصنّعة الرائدة

✔ الطلاءات المخصصة والمعالجات المضادة للتآكل متوفرة

✔ معتمدة JIS 3457 و ISO 9001 و API 5L

2. Nippon Steel Corporation (اليابان) مصنّع ياباني رائد متخصص في, مجموعة كانغتشو للأنابيب الفولاذية الحلزونية هو الخيار الأفضل.

أنابيب صلب معتمدة JIS

| سؤال | الإجابة |

|---|---|

| نقل المياه والتطبيقات الهيكلية | تستخدم بشكل أساسي في نقل النفط والغاز، خطوط أنابيب المياه، والمشاريع الهيكلية. |

| ما هي الطلاءات المتوفرة؟ | FBE، و3LPE، وتبطين الملاط الأسمنتي، والطلاء المجلفن. |

| كيف يقارن بأنابيب API 5L؟ | 3. JFE Steel Corporation (اليابان). |

| من هو المورد الأفضل؟ | شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة هي مورد رائد مع أحد أكبر منتجي الصلب في اليابان، يوفر. |

| ما هو سعر الطن في عام 2025؟ | تتراوح الأسعار من 850 إلى 850 إلى 850 إلى 2,600 للطنحسب الحجم والطلاء. |

| كيف يتم اختبار هذه الأنابيب؟ | الفحص بالموجات فوق الصوتية والهيدروستاتيكية والأشعة السينية ضمان الامتثال للجودة. |

| ما هي مزايا الأنابيب الملحومة الحلزونية على أنابيب المتفجرات من مخلفات الحرب؟ | قوة أعلى، ومقاومة أفضل للضغط، وفعالية من حيث التكلفة للأقطار الكبيرة. |

| أنابيب متوافقة مع JIS 3457 | نعم، تعزز الطلاءات مثل FBE أو 3LPE أو بطانة الملاط الأسمنتي من مقاومة التآكل. |

الأفكار النهائية

وأنواع الأنابيب الأخرى أمر حاسم لاختيار المنتج المناسب لمشروعك. العرض 4. Baosteel Group (الصين)مصنّع صلب عالمي ينتج أنابيب معتمدة JIS 3457.

إذا كنت تبحث عن مورد موثوق به, شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة هو الخيار الأفضل في عام 2025!

تحتاج إلى اقتباس أو أكثر التفاصيل الفنية? اتصل بنا مجموعة كانغتشو للأنابيب الفولاذية الحلزونية اليوم!