الشركة المصنعة للأنابيب الملحومة الحلزونية EN 10217

توافر المخزون مخزون كبير جاهز للشحن الفوري.

ضمان الجودة

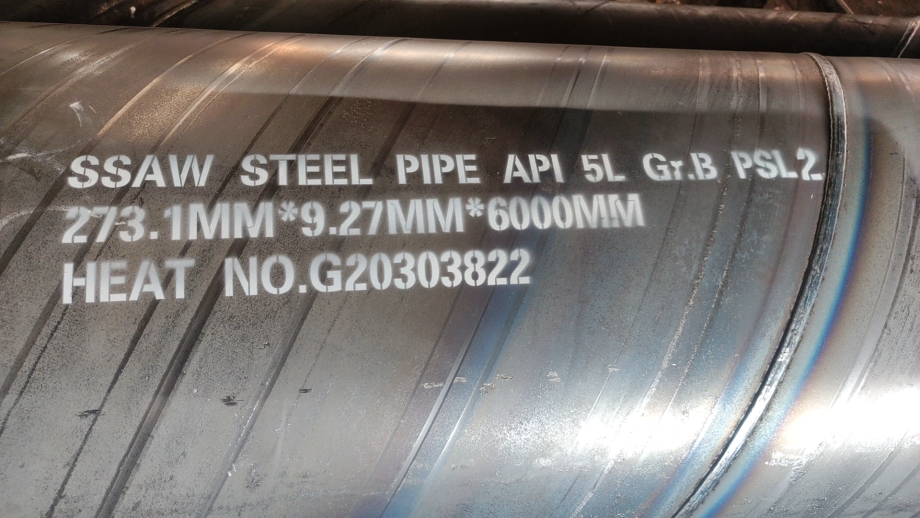

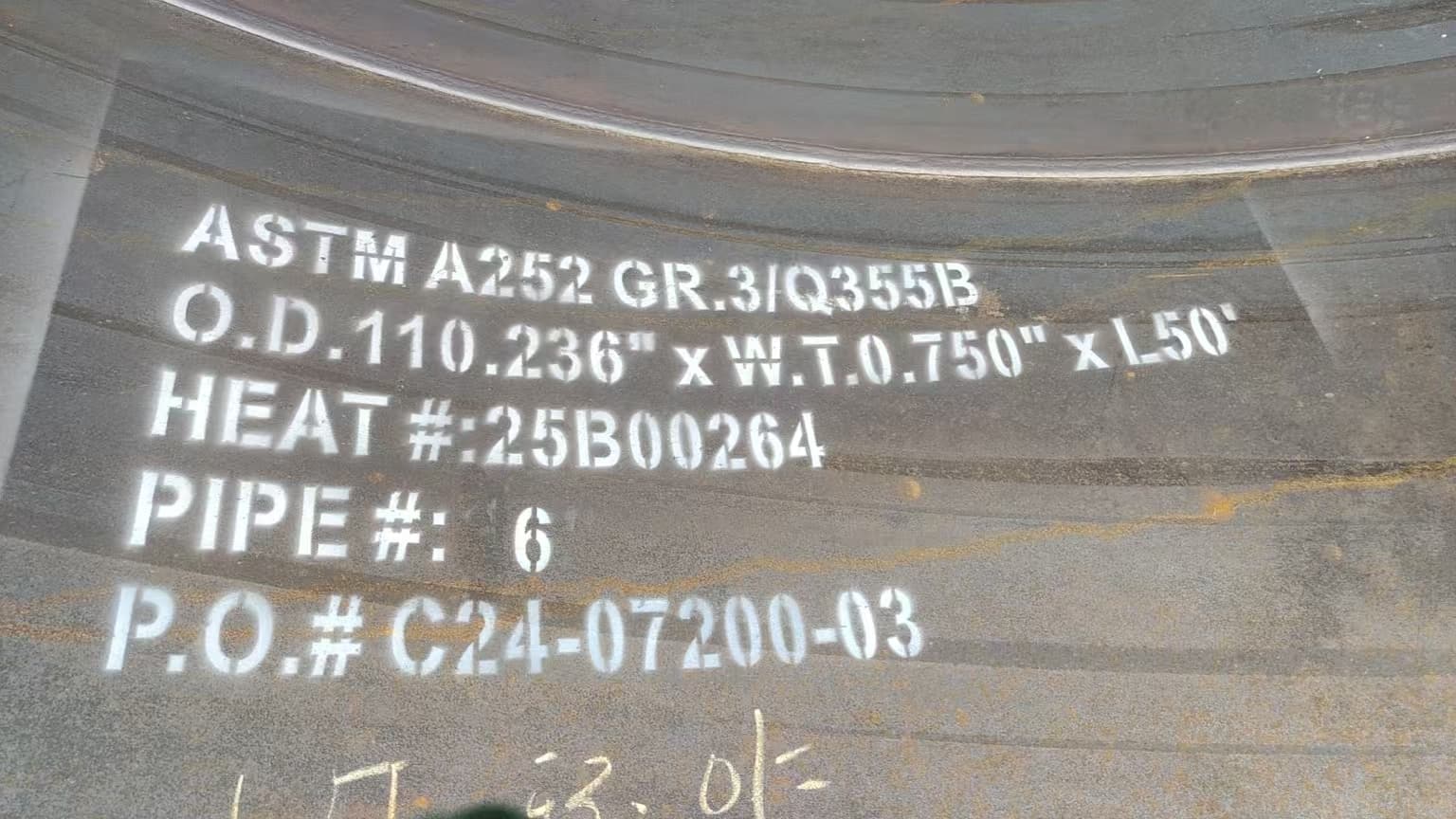

يخضع كل أنبوب لاختبارات صارمة، بما في ذلك الفحص بالموجات فوق الصوتية والاختبار الهيدروستاتيكي والفحص التلفزيوني الصناعي، مما يضمن الامتثال لشهادات API 5L وشهادات الاتحاد الأوروبي.

خدمة OEM & ODM

نحن نقدم حلولاً قابلة للتخصيص بالكامل، بدءاً من اختيار المواد إلى الطلاءات والأبعاد المتخصصة، مما يلبي احتياجات الصناعة المتنوعة.

التوصيل في الوقت المحدد

من خلال 13 خط إنتاج، و4 خطوط مضادة للتآكل، وقواعد تصنيع متعددة، نضمن كفاءة الإنتاج والتسليم في الوقت المناسب للأسواق العالمية.

شارك هذا المنتج

الحل الشامل

بدءاً من التصميم وحتى الإنتاج، نقدم حلولاً مخصصة للأنابيب الفولاذية الحلزونية، بما في ذلك الطلاءات المضادة للتآكل وضمان الجودة.

نطاق واسع الحجم

تتراوح أنابيبنا من Φ219 مم إلى Φ3500 مم، مع خيارات متنوعة لسُمك الجدار، بما يلبي متطلبات المشاريع المتنوعة.

المعايير الدولية

منتجاتنا معتمدة وفقًا لمعايير API 5L وSY/T وGB/T، وهي تلبي لوائح الصناعة العالمية من حيث الموثوقية والمتانة.

نظرة عامة على أنبوب اللحام الحلزوني EN 10217

أنبوب اللحام الحلزوني EN 10217 هو معيار أوروبي لـ أنابيب الصلب الملحومة المستخدمة في التطبيقات الضاغطة مثل الغلايات وخطوط الأنابيب وأنظمة نقل السوائل الصناعية. هذا المعيار صادر عن اللجنة الأوروبية للتوحيد القياسي (CEN) وينطبق على أنابيب الصلب الملحومة لأغراض الضغطإرشادات CSA Z245.1 قوة ميكانيكية عالية وقابلية لحام ومقاومة للتآكل.

بخلاف EN 10219، والتي تُستخدم في التطبيقات الهيكلية، EN 10217 مصمّم خصيصًا ل أنظمة تحمل الضغط، مما يجعله مناسبًا ل خطوط الأنابيب البخارية ونقل الغاز والمصانع الصناعية للمعالجة. إن النسخة الحلزونية الملحومة من أنابيب EN 10217 (SSAW – لحام قوس تحت الماء) يسمح بـ أقطار كبيرة ومقاومة عالية للضغط واقتصادية التكلفة في البنية التحتية الصناعية والطاقة.

في هذا الدليل، سنستعرض كل ما تحتاج إلى معرفته عن أنابيب اللحام الحلزوني EN 10217بما في ذلك الشركات المصنعة الرائدة والمواصفات واتجاهات الأسعار والطلاءات والتطبيقات وعمليات اللحام.

أبرز مصنّعي أنابيب اللحام الحلزوني EN 10217

تتبع عملية خاضعة للرقابة الصارمة على الجودة يضمن مواد عالية الجودة والامتثال لمعايير EN 10217 وأداء طويل الأمد. فيما يلي بعض من مصنّعو أنابيب اللحام الحلزوني EN 10217 الرائدون مواصفات JIS 3457

1. Cangzhou Spiral Steel Pipes Group Co., Ltd.

✔ 27 عاماً من الخبرة في تصنيع أنابيب الصلب

✔ 13 خط إنتاج لـ Φ219-Φ3500 مم الأنابيب الملحومة الحلزونية

✔ معتمدة بموجب EN 10217 وISO 9001 وAPI 5L

✔ الطاقة الإنتاجية السنوية: 400,000 طن

✔ الطلاء المخصص متاح: FBE، 3LPE، تبطين الملاط الأسمنتي

2. أرسيلور ميتال (أوروبا)

شركة عالمية رائدة في تصنيع أنابيب الضغط، وتزوّد أنابيب متوافقة مع EN 10217 لـ التطبيقات الصناعية والطاقة.

3. فالوريك (فرنسا)

مورد رئيسي متخصص في أنابيب ملحومة عالية الضغط لـ الغلايات وخطوط الغاز والمصانع الصناعية للمعالجة.

4. تاتا ستيل أوروبا

مصنّع أوروبي رئيسي ينتج أنابيب معتمدة بموجب EN 10217 لـ نقل النفط والغاز.

5. Jindal Steel & Power (الهند)

مورد مشهور ل أنابيب اللحام الحلزوني EN 10217 لـ خطوط الأنابيب الضاغطة ونقل السوائل الصناعية.

يضمن كل من هذه الشركات المصنعة الامتثال الصارم لمعايير EN 10217ضماناً لـ متانة عالية وقابلية لحام ومقاومة للتآكل.

أنبوب اللحام الحلزوني EN 10217 مقابل معايير الأنابيب الأخرى

يعتمد اختيار الأنبوب الفولاذي المناسب على التطبيق، والمتانة، والتكلفة، والقوة. إليك الطريقة أنبوب اللحام الحلزوني EN 10217 بالمقارنة مع معايير الأنابيب الشائعة الأخرى:

| الميزة | أنبوب اللحام الحلزوني EN 10217 | أنبوب هيكلي EN 10219 | أنابيب API 5L الملحومة | الأنابيب الملحومة 3183 ISO 3183 |

|---|---|---|---|---|

| عملية التصنيع | اللحام بالقوس الحلزوني المغمور الحلزوني (HSAW) | مجلفن بارد HSAW | الماسورة SAW أو المتفجرات من مخلفات الحرب | الماسورة SAW أو المتفجرات من مخلفات الحرب |

| القوة والمتانة | عالية للتطبيقات الضاغطة | عالية للاستخدام الهيكلي | مرتفع للنفط والغاز | مرتفع للنفط والغاز |

| مقاومة الضغط | ممتاز | معتدل | متفوقة | متفوقة |

| مقاومة التآكل | يمكن تحسينه بالطلاء | يتطلب طلاءات | يتطلب طلاءات | يتطلب طلاءات |

| التكلفة | فعالة من حيث التكلفة | فعالة من حيث التكلفة | معتدل | معتدل |

| الحجم المتاح | قطر كبير (حتى 3500 مم) | قطر كبير | قطر كبير | قطر كبير |

| التطبيق | خطوط الأنابيب الضاغطة والغلايات وخطوط الغاز | هيكلية، جسور، أكوام | النفط والغاز، والصناعة | النفط والغاز، والصناعة |

لماذا تختار أنابيب اللحام الحلزوني EN 10217؟

✔ قوة عالية للتطبيقات تحمل الضغط

✔ تكاليف التصنيع

✔ مثالية لنقل البخار والغاز والسوائل

✔ سهلة اللحام والتركيب في التطبيقات الصناعية

سعر أنبوب اللحام الحلزوني EN 10217 للطن في 2025

سعر أنابيب اللحام الحلزوني EN 10217 ، يضمن هذا المعيار درجة الصلب، والطلاءات، والطلب، وموقع التصنيعقوة عالية، مقاومة للتآكل، ومتانة

| قطر الأنبوب (مم) | سُمك الجدار (مم) | سعر الطن (بالدولار الأمريكي) |

|---|---|---|

| 219 – 600 | 6 – 10 | 950−950 – 950−1,400 |

| 610 – 1200 | 8 – 14 | 1,250−1,250 – 1,250−1,750 |

| 1220 – 1800 | 10 – 16 | 1,450−1,450 – 1,450−2,100 |

| 2000 – 3500 | 12 – 25 | 1,900−1,900 – 1,900−2,900 |

العوامل المؤثرة في السعر:

✔ الفولاذ الأسعار - تؤثر التقلبات في تكاليف المواد الخام على الأسعار.

✔ تكاليف التصنيع - نفقات العمالة والطاقة والنقل.

✔ الطلاءات والمعالجات - تزيد الطلاءات الإضافية المضادة للتآكل من السعر.

✔ طلب الكمية - غالباً ما تحصل الطلبات بالجملة على أسعار أفضل.

تقدم مجموعة أنابيب الصلب الحلزونية الحلزونية من تشانجتشو أنابيب اللحام الحلزوني EN 10217 عالية الجودة بأسعار تنافسية.

عملية لحام أنبوب اللحام الحلزوني EN 10217 وتصنيعه

كيف يتم تصنيع أنابيب اللحام الحلزوني EN 10217؟

عملية تصنيع أنابيب اللحام الحلزوني EN 10217 يتبع لوائح جودة صارمة لضمان مقاومة عالية للضغط ومتانة وامتثال للمعايير الأوروبية. فيما يلي نظرة عامة على عملية الإنتاج خطوة بخطوة:

- اختيار لفائف الصلب

- عالية الجودة الفولاذ الإنشائي من غير السبائك والحبيبات الدقيقة يتم اختيارها وفقًا ل مواصفات مواد EN 10217.

- تشمل درجات الصلب الشائعة ما يلي P235TR1، P235TR2، P265TR1، وP265TR2.

- عملية التشكيل الحلزوني

- يُطعَم الشريط الفولاذي في آلة التشكيل تُغذى باستمرار في آلة تشكيلحيث يكون ملفوفة على شكل حلزوني.

- إن هيكل الخياطة الحلزونية يسمح بـ تعامل أفضل مع الضغط والمرونة.

- اللحام بالقوس المغمور (SAW)

- اللحام بالقوس المغمور على الوجهين (DSAW) يُستخدم لإنشاء لحامات قوية ومتينة.

- هذا يضمن قوة ميكانيكية عالية وتوحيد ومقاومة للإجهاد.

- مراقبة الجودة والاختبارات

- اختبار بالموجات فوق الصوتية والأشعة السينية يتم إجراؤها لاكتشاف العيوب الداخلية والخارجية.

- CSA Z245.1 مثالية للمشاريع الكندية والأمريكية الشمالية، بينما يُستخدم API 5L عالميًا يضمن أن الأنابيب قادرة على تحمل ضغوط تشغيل عالية.

- الطلاء وعمليات مكافحة التآكل

- الأنابيب مطلية بما يلي راتنج الإيبوكسي المرتبط بالاندماج (FBE) أو 3LPE أو طلاء الزنك لتعزيز مقاومة التآكل.

- الفحص النهائي والاعتماد

- تُفحص الأنابيب بحثاً عن دقة أبعاد ومقاومة ضغط وجودة سطح.

- معتمدة بموجب معايير الجودة EN 10217 وISO 9001.

تقنيات اللحام المستخدمة في أنابيب الحلزوني EN 10217

| طريقة اللحام | المزايا |

|---|---|

| اللحام بالقوس المغمور (SAW) | تغلغل عميق، ولحامات قوية ومتجانسة |

| اللحام على الوجهين (DSAW) | يضمن قوة موحدة ويمنع نقاط الضعف |

| الاختبار الهيدروستاتيكي | التحقق من مقاومة الضغط، وضمان عدم وجود تسربات |

تضمن شركة مجموعة كانجتشو للأنابيب الفولاذية الحلزونية المحدودة جميع الأنابيب تتوافق مع معايير EN 10217 من خلال تقنيات لحام حديثة ومراقبة جودة صارمة.

موردو ومصدري أنابيب اللحام الحلزوني EN 10217

إذا كنت تبحث عن استيراد أنابيب اللحام الحلزوني EN 10217العمل مع مصدّر موثوق به ، مما يجعلها الخيار المفضل لـ مصدّر رائد في مجال التصدير بسبب سعة تصنيع عالية وأسعار تنافسية ومراقبة جودة قوية.

أبرز مصدري الصين لأنابيب اللحام الحلزوني EN 10217

| اسم الشركة | الموقع | الطاقة الإنتاجية السنوية |

|---|---|---|

| شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة | خبي، الصين | 400,000 طن |

| مجموعة باوستيل | شنغهاي، الصين | أكثر من 500,000 طن |

| شركة تيانجين لأنابيب الصلب | تيانجين، الصين | 300,000 طن |

لماذا تختار مجموعة أنابيب الصلب الحلزوني في تشانغتشو لأنابيب EN 10217؟

✔ 27 عاماً من الخبرة في تصنيع الأنابيب الفولاذية

✔ معتمدة بموجب EN 10217 وISO وCE

✔ 13 خط إنتاج، تغطي الأقطار من 219 مم إلى 3500 مم

✔ الطلاءات المخصصة والمعالجات المضادة للتآكل متوفرة

✔ شبكة تصدير قوية إلى أوروبا وأمريكا الشمالية وآسيا

بالنسبة لـ أنابيب اللحام الحلزوني EN 10217 عالية الجودة, شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة هو مورد موثوق به.

الأسئلة الشائعة: أنبوب اللحام الحلزوني EN 10217

| سؤال | الإجابة |

|---|---|

| ما هو استخدام أنبوب اللحام الحلزوني EN 10217؟ | تستخدم بشكل أساسي في التطبيقات تحمل الضغط ونقل السوائل الصناعية وخطوط الطاقة. |

| ما هي الطلاءات المتوفرة؟ | FBE، و3LPE، وتبطين الملاط الأسمنتي، والطلاء المجلفن. |

| كيف يقارن بأنابيب EN 10219 الهيكلية؟ | EN 10217 للتطبيقات الضاغطة بينما EN 10219 للاستخدام الهيكلي. |

| من هو المورد الأفضل؟ | شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة هي مورد رائد مع شهادات ISO وEN 10217. |

| ما هو سعر الطن في عام 2025؟ | تتراوح الأسعار من 950to950 إلى 950to2,900 لكل طنحسب الحجم والطلاء. |

| كيف يتم اختبار هذه الأنابيب؟ | الفحص بالموجات فوق الصوتية والهيدروستاتيكية والأشعة السينية ضمان الامتثال للجودة. |

| ما هي مزايا الأنابيب الملحومة الحلزونية على أنابيب المتفجرات من مخلفات الحرب؟ | قوة أعلى، ومقاومة أفضل للضغط، وفعالية من حيث التكلفة للأقطار الكبيرة. |

| هل تحتاج أنابيب EN 10217 إلى طلاء؟ | نعم، تعزز الطلاءات مثل FBE أو 3LPE أو بطانة الملاط الأسمنتي من مقاومة التآكل. |

| هل تتوفر أنابيب EN 10217 بأقطار كبيرة؟ | نعم، فهي متوفرة بأحجام يصل قطرها إلى 3500 مم. |

الأفكار النهائية

أنابيب اللحام الحلزوني EN 10217 تستخدم على نطاق واسع في خطوط الأنابيب الصناعية والتطبيقات تحمل الضغط والبنية التحتية للطاقة بسبب قوة عالية، ومقاومة للتآكل، وفعالية من حيث التكلفة.

إذا كنت تبحث عن مورد موثوق به, شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة هو الخيار الأفضل في عام 2025!

تحتاج إلى اقتباس أو أكثر التفاصيل الفنية? اتصل بنا مجموعة كانغتشو للأنابيب الفولاذية الحلزونية اليوم!