الشركة المصنعة للأنابيب الملحومة الحلزونية API 5l Psl2

توافر المخزون مخزون كبير جاهز للشحن الفوري.

ضمان الجودة

يخضع كل أنبوب لاختبارات صارمة، بما في ذلك الفحص بالموجات فوق الصوتية والاختبار الهيدروستاتيكي والفحص التلفزيوني الصناعي، مما يضمن الامتثال لشهادات API 5L وشهادات الاتحاد الأوروبي.

خدمة OEM & ODM

نحن نقدم حلولاً قابلة للتخصيص بالكامل، بدءاً من اختيار المواد إلى الطلاءات والأبعاد المتخصصة، مما يلبي احتياجات الصناعة المتنوعة.

التوصيل في الوقت المحدد

من خلال 13 خط إنتاج، و4 خطوط مضادة للتآكل، وقواعد تصنيع متعددة، نضمن كفاءة الإنتاج والتسليم في الوقت المناسب للأسواق العالمية.

شارك هذا المنتج

الحل الشامل

بدءاً من التصميم وحتى الإنتاج، نقدم حلولاً مخصصة للأنابيب الفولاذية الحلزونية، بما في ذلك الطلاءات المضادة للتآكل وضمان الجودة.

نطاق واسع الحجم

تتراوح أنابيبنا من Φ219 مم إلى Φ3500 مم، مع خيارات متنوعة لسُمك الجدار، بما يلبي متطلبات المشاريع المتنوعة.

المعايير الدولية

منتجاتنا معتمدة وفقًا لمعايير API 5L وSY/T وGB/T، وهي تلبي لوائح الصناعة العالمية من حيث الموثوقية والمتانة.

نظرة عامة على أنابيب اللحام الحلزوني API 5L PSL2

أنابيب اللحام الحلزوني API 5L PSL2 هو أنبوب فولاذي عالي القوة يُستخدم في نقل النفط والغاز، خطوط الأنابيب المائية، والتطبيقات الصناعية. يُصنع وفقًا لمعيار API 5L، الصادرة عن معهد البترول الأمريكي (API)، الذي يضمن رقابة صارمة على الجودة، متانة، وأداءً عاليًا.

تُصنف أنابيب API 5L إلى مستويين لمواصفات المنتج (PSL):

- PSL1: أنبوب فولاذي أساسي لـ التطبيقات منخفضة الضغط.

- PSL2: أنبوب عالي الجودة مع يتميز بخصائص ميكانيكية محسنة، متطلبات لحام قاسية، واختبارات أكثر صرامة لـ التطبيقات عالية الضغط والحرجة.

الميزات الرئيسية لأنابيب اللحام الحلزوني API 5L PSL2

✔ يُصنع باستخدام اللحام تحت الغاطس (SAW) أو اللحام تحت الغاطس الحلزوني (HSAW)

✔ قوة وصلابة أعلى من أنابيب PSL1

✔ مصمم لنقل النفط والغاز والسوائل عالية الضغط

✔ متوفر في درجات الفولاذ X42، X52، X60، X70، وX80 لتصنيفات ضغط مختلفة

✔ متطلبات اختبار صارمة: اختبار صدمة شاربي، اختبار صلابة، وفحص غير تدميري

في هذا الدليل، سنستكشف كل ما يتعلق بـ أنابيب اللحام الحلزوني API 5L PSL2بما في ذلك الشركات المصنعة والمواصفات واتجاهات الأسعار والطلاءات والتطبيقات وعمليات اللحام.

أبرز مصنعي أنابيب اللحام الحلزوني API 5L PSL2

تتبع عملية خاضعة للرقابة الصارمة على الجودة أمر أساسي للحصول على أنابيب عالية الجودة ومتينة ومعتمدة من API. فيما يلي بعض من أبرز مصنعي أنابيب اللحام الحلزوني API 5L PSL2 في عام 2025:

1. Cangzhou Spiral Steel Pipes Group Co., Ltd.

✔ 27 عاماً من الخبرة في تصنيع أنابيب الصلب

✔ 13 خط إنتاج لـ Φ219-Φ3500 مم الأنابيب الملحومة الحلزونية

✔ معتمدة من API 5L PSL2، ASTM A53، ASTM A252، وISO 9001

✔ الطاقة الإنتاجية السنوية: 400,000 طن

✔ الطلاء المخصص متاح: FBE، 3LPE، تبطين الملاط الأسمنتي

2. تيناريس (عالمية)

مصنع رائد عالميًا لـ أنابيب API 5L PSL2 المستخدمة في خطوط أنابيب النفط والغاز والتطبيقات البحرية.

3. فالوريك (فرنسا/ألمانيا)

متخصصة في أنابيب API 5L PSL2 عالية القوة لـ التطبيقات المائية العميقة وعالية الضغط.

4. Jindal SAW Ltd. (الهند)

شهادات ISO و JIS 3457 أنابيب API 5L كبيرة القطر لـ نقل النفط والغاز والأنابيب الصناعية.

5. Welspun Corp Ltd (الهند)

منتج رائد لـ أنابيب اللحام الحلزوني لمشاريع خطوط الأنابيب عالية الضغط والبحرية.

يضمن كل من هذه الشركات المصنعة الامتثال الصارم لمعايير API 5L PSL2ضماناً لـ متانة عالية، مقاومة للتآكل، وخصائص ميكانيكية فائقة.

أنابيب اللحام الحلزوني API 5L PSL2 مقابل معايير الأنابيب الأخرى

أنابيب ملحومة حلزونيًا CSA Z245.1 أنابيب اللحام الحلزوني API 5L PSL2 ومعايير أنابيب الفولاذ الأخرى يساعد في اختيار الأنبوب المناسب لمشروعك.

| الميزة | أنابيب اللحام الحلزوني API 5L PSL2 | أنبوب API 5L PSL1 | أنابيب ASTM A53 الملحومة | أنابيب الخوازيق ASTM A252 |

|---|---|---|---|---|

| عملية التصنيع | SAW أو HSAW | SAW أو HSAW | ERW أو SAW | SAW |

| القوة والمتانة | عالية جداً | معتدل | معتدل | عالية |

| مقاومة الضغط | متفوقة | معتدل | منخفض إلى متوسط | منخفضة |

| متطلبات الاختبار | صدمة شاربي، صلابة، غير تدميري | اختبارات ميكانيكية أساسية | بصري، هيدروستاتيكي | بصري، هيدروستاتيكي |

| مقاومة التآكل | يمكن تحسينه بالطلاء | يمكن طلاؤه | يمكن زنبركه | يتطلب طلاءات |

| التكلفة | أعلى | أقل | فعالة من حيث التكلفة | معتدل |

| أفضل حالة استخدام | خطوط أنابيب النفط والغاز، التطبيقات عالية الضغط | نقل النفط والغاز العام | نقل المياه، هيكلية | الخوازيق ودعامات الأساسات |

لماذا تختار أنابيب اللحام الحلزوني API 5L PSL2؟

✔ مصممة للتطبيقات عالية الضغط

✔ قوة فائقة ومقاومة للصدمات

✔ الاختبارات الصارمة تضمن أداءً أعلى من أنابيب PSL1

✔ يُستخدم في مشاريع البنية التحتية الحرجة للنفط والغاز والبحرية والصناعية

سعر أنبوب اللحام الحلزوني API 5L PSL2 للطن في عام 2025

سعر أنابيب اللحام الحلزوني API 5L PSL2 يعتمد على عوامل مثل درجة الصلب، والطلاءات، والطلب، وموقع التصنيعقوة عالية، مقاومة للتآكل، ومتانة

| قطر الأنبوب (مم) | سُمك الجدار (مم) | درجة الفولاذ | سعر الطن (بالدولار الأمريكي) |

|---|---|---|---|

| 219 – 600 | 6 – 10 | X42 – X52 | 1,200-1,200 - 1,200-1,800 |

| 610 – 1200 | 8 – 14 | X52 – X60 | 1,500-1,500 - 1,500-2,200 |

| 1220 – 1800 | 10 – 18 | X60 – X70 | 1,800-1,800 - 1,800-2,600 |

| 2000 – 3500 | 12 – 25 | X70 – X80 | 2,300-2,300 - 2,300-3,200 |

العوامل المؤثرة في السعر:

✔ الفولاذ الصف – الدرجات الأعلى (X60-X80) تكلف أكثر بسبب قوتها الأعلى.

✔ تكاليف التصنيع - نفقات العمالة والطاقة والنقل.

✔ الطلاءات والمعالجات - تزيد الطلاءات الإضافية المضادة للتآكل من السعر.

✔ الفوائد - تحصل طلبات الكمية الكبيرة على أسعار أفضل.

تقدم مجموعة أنابيب الصلب الحلزونية الحلزونية من تشانجتشو أنابيب اللحام الحلزوني API 5L PSL2 عالية الجودة بأسعار تنافسية.

عملية لحام أنبوب اللحام الحلزوني API 5L PSL2 وتصنيعه

كيف يُصنع أنبوب اللحام الحلزوني API 5L PSL2؟

إن أنابيب اللحام الحلزوني API 5L PSL2 تتبع عملية التصنيع تدابير صارمة لمراقبة الجودة لضمان قوة عالية، متانة، والامتثال للمعايير الدولية. فيما يلي تفاصيل عملية الإنتاج خطوة بخطوة:

1. اختيار لفائف الصلب

- عالية الجودة لفائف فولاذ الكربون يتم اختيارها بناءً على متطلبات مادة API 5L PSL2.

- تشمل درجات الصلب الشائعة ما يلي X42، X52، X60، X70، وX80، مع الدرجات الأعلى توفر قوة وضغطًا أعلى.

2. عملية التشكيل الحلزوني

- يتم تغذية شريط الفولاذ باستمرار في ماكينة التشكيلحيث يكون ملفوفة على شكل حلزوني.

- إن الخياطة الحلزونية توفر قوة ومرونة محسنةمما يجعلها مثالية ل خطوط أنابيب النفط والغاز والتطبيقات الصناعية.

3. عملية اللحام تحت الغاطس (SAW)

- اللحام بالقوس المغمور على الوجهين (DSAW) يُستخدم لإنشاء لحامات قوية وخالية من العيوب.

- تضمن طريقة اللحام هذه التغلغل العميق والتوحيد ومقاومة الإجهادمما يجعلها مثالية ل تطبيقات الضغط العالي.

4. مراقبة الجودة والاختبار

- اختبار تأثير تاربي يضمن الصلابة ومقاومة الكسور.

- الفحص بالموجات فوق الصوتية والأشعة السينية يكشف عن أي عيوب داخلية أو سطحية.

- اختبار الضغط الهيدروستاتيكي تتحقق من قدرة الأنبوب على تحمل ضغوط تشغيلية عالية.

- فحص الأبعاد يضمن الاستقامة وتوحيد السُمك ودقة القطر.

5. الطلاء والحماية من التآكل

- يمكن طلاء الأنابيب بما يلي إيبوكسي الربط الاندماجي (FBE)، 3LPE، البيتومين، أو بطانة الملاط الإسمنتي للمقاومة التآكل، والرطوبة، والأضرار البيئية.

6. الفحص النهائي والاعتماد

- يتم فحص كل أنبوب من أجل الامتثال لـ API 5L PSL2، ISO 9001، وشهادات الجودة ذات الصلة الأخرى.

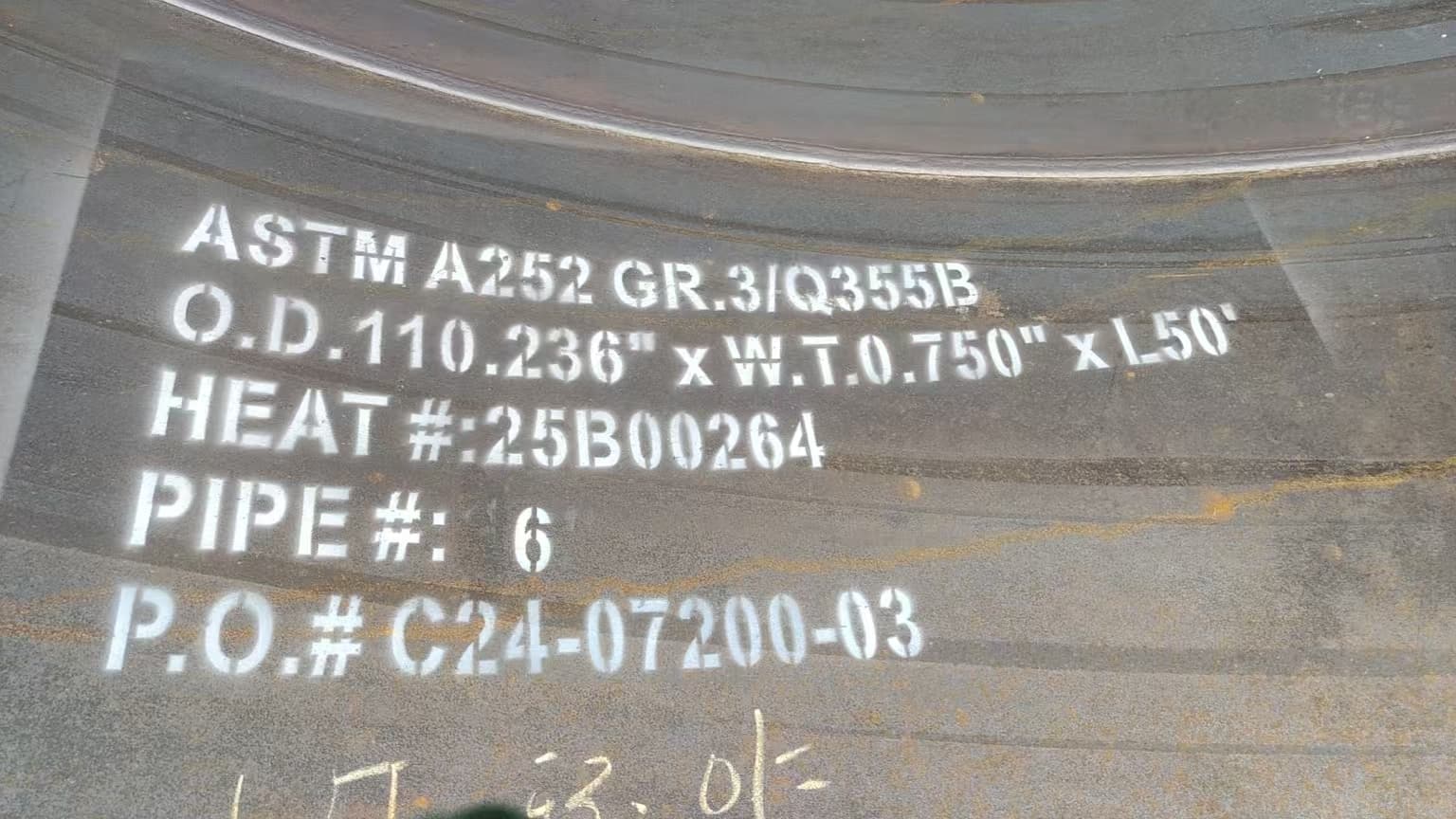

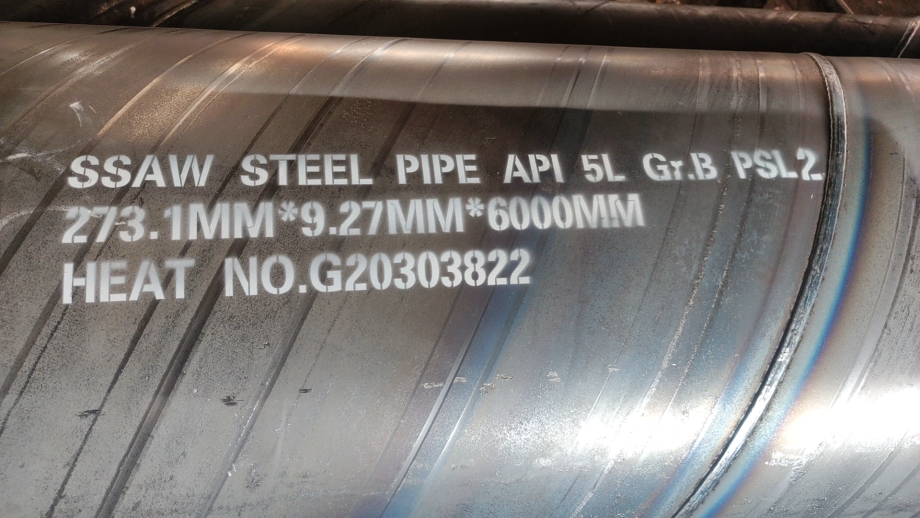

- يتم تمييز الأنابيب بـ الدرجة والحجم ورقم الحرارة واسم الشركة المصنعة للتتبع الكامل.

تقنيات اللحام المستخدمة في أنابيب اللحام الحلزوني API 5L PSL2

| طريقة اللحام | المزايا |

|---|---|

| اللحام بالقوس المغمور (SAW) | تغلغل عميق، ولحامات قوية ومتجانسة |

| اللحام على الوجهين (DSAW) | يضمن قوة موحدة ويمنع نقاط الضعف |

| الاختبار الهيدروستاتيكي | التحقق من مقاومة الضغط، وضمان عدم وجود تسربات |

| الفحص بالموجات فوق الصوتية والأشعة السينية | يكشف عن العيوب الداخلية لتعزيز السلامة |

تضمن شركة مجموعة كانجتشو للأنابيب الفولاذية الحلزونية المحدودة جميع الأنابيب تتوافق مع معايير API 5L PSL2 من خلال تقنيات اللحام المتقدمة ومراقبة الجودة الصارمة.

طلاء أنبوب اللحام الحلزوني API 5L PSL2 ومعالجة مكافحة التآكل

الأنابيب المستخدمة في نقل النفط والغاز، البحرية، والتطبيقات الصناعية غالبًا ما يتعرضون ل البيئات التآكلية، الظروف عالية الضغط، ودرجات الحرارة القصوى. تطبيق الطلاءات الواقية يساعد على إطالة عمر الخدمة ومنع التآكل.

خيارات الطلاء الشائعة لأنابيب API 5L PSL2

| عملية لحام وتصنيع أنابيب ملحومة حلزونيًا CSA Z245.1 | المزايا | . إليك جدول تسعير تقديري لعام 2025: |

|---|---|---|

| . إليك تفصيلًا لكيفية إنتاج هذه الأنابيب: | مقاومة عالية للتآكل، والتصاق قوي | خطوط أنابيب النفط والغاز، الأنابيب الصناعية |

| تشمل المواد الشائعة | مقاومة ممتازة للصدمات والحماية من الرطوبة | خطوط الأنابيب تحت الأرض، التطبيقات البحرية |

| تعزز هذه العملية | فعالة من حيث التكلفة وجيدة للتطبيقات تحت الأرض | الخوازيق الإنشائية ومشاريع الصرف الصحي |

| يتم تشكيل اللحام، مما يعزز مقاومة الضغط. | يمنع التآكل الداخلي، مثالي لنقل المياه | خطوط أنابيب نقل المياه، إمداد المياه الصناعي |

لماذا الطلاء مهم لأنابيب API 5L PSL2؟

✔ يمنع الصدأ والتآكل في البيئات القاسية

✔ يحسن السلامة الهيكلية ويطيل عمر الخدمة

✔ يعزز مقاومة المواد الكيميائية والرطوبة والمياه المالحة

✔ يقلل من تكاليف الصيانة للمشاريع طويلة الأمد

تقدم مجموعة أنابيب الصلب الحلزونية الحلزونية من تشانجتشو . يتم ختم الأنابيب وشهادتها وفقًا لـ استنادًا إلى متطلبات المشروع.

أنبوب اللحام الحلزوني API 5L PSL2 للتطبيقات البحرية وعالية الضغط

إحدى التطبيقات الأكثر أهمية لـ أنابيب اللحام الحلزوني API 5L PSL2 في البيئات البحرية وعالية الضغطبما في ذلك استكشاف النفط والغاز في الأعماق، خطوط الأنابيب تحت البحر، وشبكات التكرير.

لماذا أنابيب API 5L PSL2 مثالية للتطبيقات البحرية وعالية الضغط؟

✔ خصائص ميكانيكية فائقة للتعامل مع الضغط القصوى

✔ طلاءات مقاومة للتآكل لعمر خدمة طويل في الظروف تحت البحر

✔ درجات فولاذ عالية القوة (X60، X70، X80) متوفرة

✔ الاختبارات الصارمة تضمن الامتثال لمعايير الصناعة البحرية

مقارنة API 5L PSL2 بمعايير خطوط الأنابيب البحرية الأخرى

| الميزة | أنابيب اللحام الحلزوني API 5L PSL2 | أنبوب API 5L PSL1 | أنبوب سلس ASTM A106 |

|---|---|---|---|

| القوة وتحمل الأحمال | عالية جداً | معتدل | عالية جداً |

| مقاومة التآكل | يمكن تحسينه بالطلاء | يتطلب طلاءات | يتطلب طلاءات |

| التكلفة | أعلى | أقل | باهظة الثمن |

| توافر القطر | قطر كبير | قطر كبير | المواد الخام والقطر والطلاءات والطلب العالمي |

| أفضل حالة استخدام | خطوط أنابيب بحرية عالية الضغط | نقل النفط والغاز العام | التكرير، التطبيقات عالية الحرارة |

مجموعة كانجتشو للأنابيب الفولاذية الحلزونية تورد أنابيب API 5L PSL2 عالية الجودة لـ مشاريع الحفر البحري، خطوط الأنابيب في الأعماق، وشبكات التكرير.

موردو ومصدري أنبوب اللحام الحلزوني API 5L PSL2

إذا كنت تبحث عن استيراد أنابيب اللحام الحلزوني API 5L PSL2العمل مع مصدّر موثوق به ، مما يجعلها الخيار المفضل لـ مصدّر رائد في مجال التصدير بسبب قدرة إنتاج عالية، وأسعار تنافسية، ومراقبة صارمة للجودة.

أبرز مصدري الصينيين لأنابيب اللحام الحلزوني API 5L PSL2

| اسم الشركة | الموقع | الطاقة الإنتاجية السنوية |

|---|---|---|

| شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة | خبي، الصين | 400,000 طن |

| مجموعة باوستيل | شنغهاي، الصين | أكثر من 500,000 طن |

| شركة تيانجين لأنابيب الصلب | تيانجين، الصين | 300,000 طن |

لماذا تختار مجموعة أنابيب الحلزوني في تشانغتشو لأنابيب API 5L PSL2؟

✔ 27 عاماً من الخبرة في تصنيع الأنابيب الفولاذية

✔ معتمدة من API 5L PSL2، ISO 9001، وAPI

✔ 13 خط إنتاج، تغطي الأقطار من 219 مم إلى 3500 مم

✔ الطلاءات المخصصة والمعالجات المضادة للتآكل متوفرة

✔ شبكة تصدير قوية إلى أمريكا الشمالية وأوروبا وآسيا

بالنسبة لـ أنابيب اللحام الحلزوني API 5L PSL2 عالية الجودة, شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة هو مورد موثوق به.

الأفكار النهائية

أنابيب اللحام الحلزوني API 5L PSL2 تستخدم على نطاق واسع في التطبيقات البحرية، النفط والغاز، وعالية الضغط بسبب قوة فائقة، مقاومة للتآكل، ومعايير جودة صارمة.

بالنسبة لـ أنابيب API 5L PSL2 عالية الجودة الممتازة, شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة هو الخيار الأفضل في عام 2025!

تحتاج إلى اقتباس أو أكثر التفاصيل الفنية? اتصل بنا مجموعة كانغتشو للأنابيب الفولاذية الحلزونية اليوم!