الشركة المصنعة للأنابيب المغلفة بقطران الفحم الإيبوكسي

توافر المخزون مخزون كبير جاهز للشحن الفوري.

ضمان الجودة

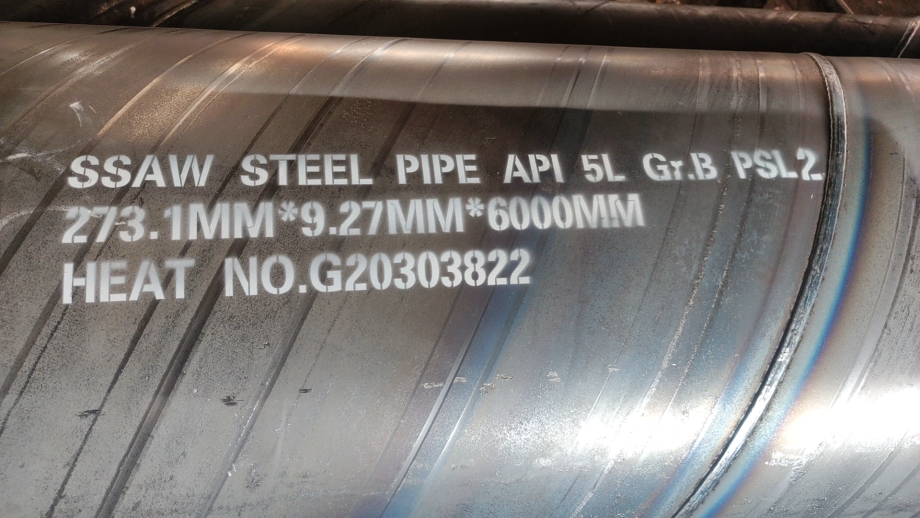

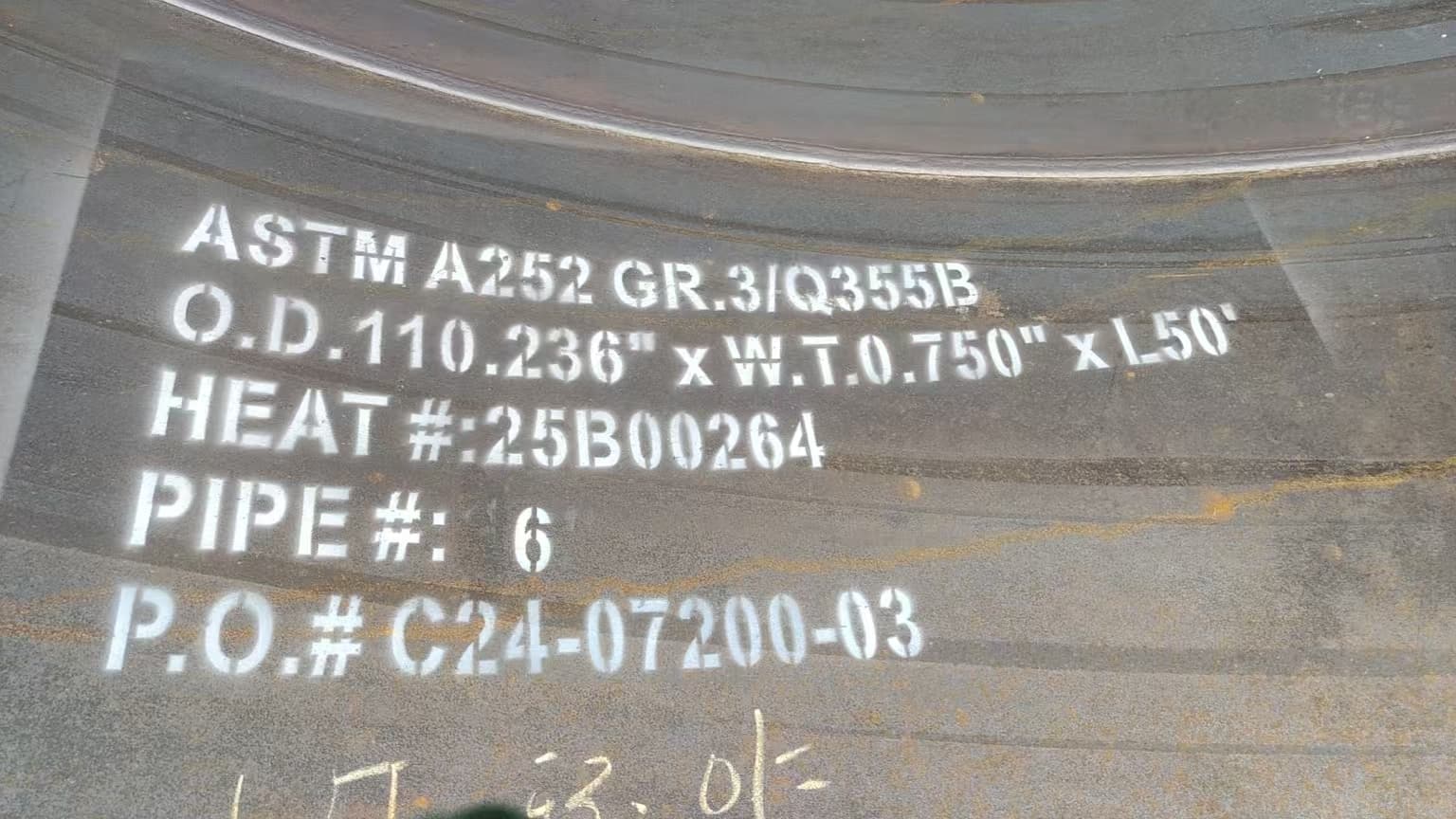

يخضع كل أنبوب لاختبارات صارمة، بما في ذلك الفحص بالموجات فوق الصوتية والاختبار الهيدروستاتيكي والفحص التلفزيوني الصناعي، مما يضمن الامتثال لشهادات API 5L وشهادات الاتحاد الأوروبي.

خدمة OEM & ODM

نحن نقدم حلولاً قابلة للتخصيص بالكامل، بدءاً من اختيار المواد إلى الطلاءات والأبعاد المتخصصة، مما يلبي احتياجات الصناعة المتنوعة.

التوصيل في الوقت المحدد

من خلال 13 خط إنتاج، و4 خطوط مضادة للتآكل، وقواعد تصنيع متعددة، نضمن كفاءة الإنتاج والتسليم في الوقت المناسب للأسواق العالمية.

شارك هذا المنتج

الحل الشامل

بدءاً من التصميم وحتى الإنتاج، نقدم حلولاً مخصصة للأنابيب الفولاذية الحلزونية، بما في ذلك الطلاءات المضادة للتآكل وضمان الجودة.

نطاق واسع الحجم

تتراوح أنابيبنا من Φ219 مم إلى Φ3500 مم، مع خيارات متنوعة لسُمك الجدار، بما يلبي متطلبات المشاريع المتنوعة.

المعايير الدولية

منتجاتنا معتمدة وفقًا لمعايير API 5L وSY/T وGB/T، وهي تلبي لوائح الصناعة العالمية من حيث الموثوقية والمتانة.

نظرة عامة على أنبوب مغلف بإيبوكسي قطران الفحم

أن 3300–4500 هو أنابيب فولاذية عالية الأداء مقاومة فائقة للتآكل، وقوة ميكانيكية عالية، ومتانة استثنائية مزيج من راتنج الإيبوكسي وقطران الفحمتوفير مقاومة فائقة للتآكل، والكشط، والاستقرار الكيميائي. يستخدم هذا النوع من الطلاء على نطاق واسع في خطوط أنابيب النفط والغاز، ونقل المياه، وأنظمة الصرف الصحي، والبيئات البحرية حيث حماية طويلة الأمد ضد الرطوبة والمواد الكيميائية والظروف القاسية أمر أساسي.

الميزات الرئيسية لأنبوب مغلف بإيبوكسي قطران الفحم

✔ مقاومة استثنائية للتآكل والمواد الكيميائية

✔ طلاء مقاوم للكشط وشديد المتانة

✔ التصاق قوي بالأسطح الفولاذية، مما يقلل من مخاطر فشل الطلاء

✔ مثالي للتطبيقات تحت الأرض والغاطسة

✔ حماية طويلة الأمد تقلل تكاليف الصيانة

سيغطي هذا الدليل كل شيء عن أنابيب مغلفة بإيبوكسي قطران الفحمبما في ذلك طلاءات 3LPE عالية الأداء لخطوط الأنابيب البحرية والصناعية.

أبرز مصنعي أنابيب مغلفة بإيبوكسي قطران الفحم

تتبع عملية خاضعة للرقابة الصارمة على الجودة يضمن أنبوب مطلي بـ3LPE مقابل الأنابيب المطليّة الأخرى. فيما يلي بعض من مصنعو أنابيب مغلفة بإيبوكسي قطران الفحم الرائدون في 2025:

1. Cangzhou Spiral Steel Pipes Group Co., Ltd.

✔ 27 عاماً من الخبرة في تصنيع أنابيب الصلب

✔ 13 خط إنتاج لـ Φ219-Φ3500 مم الأنابيب الملحومة الحلزونية

✔ حلول طلاء إيبوكسي قطران الفحم، والإيبوكسي المركب بالاندماج (FBE)، و3LPE

✔ الطاقة الإنتاجية السنوية: 400,000 طن

✔ طلاءات معتمدة من ISO 9001 وAPI 5L وASTM معتمدة من ASTM

2. Baosteel Group (الصين)

A أكبر منتج للصلب متخصصون في أنابيب مغلفة بإيبوكسي قطران الفحم لنقل النفط وخطوط المياه.

3. Jindal SAW Ltd (الهند)

شهادات ISO و JIS 3457 أنابيب مغلفة بإيبوكسي قطران الفحم لـ أنظمة المياه البلدية والتطبيقات الصناعية.

4. تيناريس (عالمي)

شركة تصنيع رائدة تقدم طلاءات إيبوكسي قطران الفحم عالية الأداء لخطوط الأنابيب البحرية والخارجية.

5. Welspun Corp Ltd (الهند)

A رائد عالمي في 2.5 – 3.5 ممتوفير طلاءات إيبوكسي قطران الفحم للبيئات القاسية.

يضمن كل من هذه الشركات المصنعة 2700–3700ضماناً لـ متانة وأداء عاليان.

أنبوب مغلف بإيبوكسي قطران الفحم مقابل الأنابيب المغلفة الأخرى

اختيار المناسب نظام الطلاء يعتمد على عوامل التطبيق، والمتانة، والتكلفة، والعوامل البيئية. إليك الطريقة 3300–4500 مقارنة بأنواع الطلاء الأخرى:

| الميزة | 3300–4500 | الأنابيب المغطاة بالإيبوكسي المترابط بالاندماج (FBE) | أنابيب مغلفة بالبولي إيثيلين ثلاثي الطبقات (3LPE) | أنابيب مطلية بـ3LPE عالية الجودة بأسعار تنافسية |

|---|---|---|---|---|

| مقاومة التآكل | ممتاز | عالية | عالية جداً | عالية |

| مقاومة المواد الكيميائية | ممتاز | عالية | معتدل | عالية |

| الالتصاق بالفولاذ | قوي جداً | قوي | قوي جداً | قوي جداً |

| مقاومة التآكل | عالية جداً | معتدل | عالية | عالية جداً |

| أفضل حالة استخدام | خطوط الأنابيب تحت الأرض، وأنظمة الصرف الصحي، والتطبيقات البحرية | خطوط أنابيب النفط والغاز والتطبيقات البحرية | خطوط الأنابيب تحت الأرض، المناطق شديدة التأثير | تتضمن تطبيق |

لماذا تختار أنابيب مغلفة بإيبوكسي قطران الفحم؟

✔ مقاومة فائقة للتآكل والمواد الكيميائية والكشط

✔ الأفضل للتطبيقات تحت الأرض والغاطسة والصناعية القاسية

✔ حل اقتصادي وحماية طويلة الأمد

✔ التصاق ممتاز وقوة ميكانيكية

سعر أنبوب مغلف بإيبوكسي قطران الفحم للطن في 2025

سعر أنابيب مغلفة بإيبوكسي قطران الفحم ، يضمن هذا المعيار قطر الأنبوب، وسُمك الجدار، وسُمك الطلاء، وتكاليف المواد الخامقوة عالية، مقاومة للتآكل، ومتانة

| قطر الأنبوب (مم) | سُمك الجدار (مم) | سُمك الطلاء (ميكرومتر) | سعر الطن (بالدولار الأمريكي) |

|---|---|---|---|

| 219 – 600 | 6 – 10 | 300 – 500 | 1,600−1,600 – 1,600−2,400 |

| 610 – 1200 | 8 – 14 | 400 – 600 | 2,000−2,000 – 2,000−2,800 |

| 1220 – 1800 | 10 – 18 | 500 – 800 | 2,500−2,500 – 2,500−3,500 |

| 2000 – 3500 | 12 – 25 | 600 – 1000 | 3,100−3,100 – 3,100−4,200 |

العوامل المؤثرة في السعر:

✔ سُمك الطلاء - تكلف الطلاءات الأكثر سماكة أكثر بسبب استخدام مواد إضافية.

✔ قطر الأنبوب وطوله - تتطلب الأنابيب الأكبر حجمًا المزيد من مواد الطلاءزيادة التكاليف

✔ تكاليف التصنيع - تؤثر نفقات العمالة والطاقة والنقل على الأسعار.

✔ الفوائد - تحصل طلبات الكمية الكبيرة على أسعار أفضل.

تقدم مجموعة أنابيب الصلب الحلزونية الحلزونية من تشانجتشو أنابيب مغلفة بإيبوكسي قطران الفحم عالية الجودة بأسعار تنافسية.

عملية تصنيع أنبوب مغلف بإيبوكسي قطران الفحم والرقابة على الجودة

كيف يتم تصنيع أنبوب مغلف بإيبوكسي قطران الفحم؟

إن عملية طلاء إيبوكسي قطران الفحم يتضمَّن تطبيق مزيج من راتنج الإيبوكسي وقطران الفحم على سطح الأنبوب الفولاذي. وينتج عن ذلك طبقة متينة مقاومة للتآكل والكشطمما يجعلها مثالية ل التطبيقات تحت الأرض والغاطسة والصناعية. فيما يلي تفصيل لـ عملية تصنيع أنبوب مغلف بإيبوكسي قطران الفحم خطوة بخطوة:

1. تحضير السطح

- تُضْمَد على الأنبوب. توفر حماية ميكانيكية لإزالة الصدأ، والقشور، والملوثات.

- A ، مقاومة للصدمات، وحماية من الأشعة فوق البنفسجية. يُسمَح للأنبوب المطلي بالتبريد التصاق طلاء إيبوكسي قطران الفحم.

2. تطبيق طلاء إيبوكسي قطران الفحم

- A مزيج إيبوكسي قطران الفحم السائل باستخدام تقنيات الرش.

- إن يوضع الطلاء على طبقات متعددةحسب السُمك المطلوب ومواصفات المشروع.

- إن يضمن راتنج الإيبوكسي التصاقًا قويًا، بينما يعزز قطران الفحم مقاومة الكيماويات والرطوبة.

3. المعالجة والتصلب

- الأنابيب المغلفة معالجتها في بيئة خاضعة للرقابة لضمان التصلب والترابط الكيميائي المناسب.

- تضمن هذه الخطوة أن يظل الطلاء متينًا ومرنًا ومقاومًا للتشقق.

4. مراقبة الجودة والاختبار

- قياس سماكة الطلاء يضمن يتم تحقيق السُمك المطلوب.

- اختبار الالتصاق يتحقق من قوة الالتصاق بين الطلاء و الفولاذ السطح.

- اختبار مقاومة الكيماويات يقيِّم الطلاء الأداء في البيئات العدوانية.

- اختبار مقاومة الكشط يقيِّم المتانة طويلة الأمد في التطبيقات عالية الارتداء.

5. الفحص النهائي والتعبئة والتغليف

- الأنابيب فحص بصري للتوحيد وعيوب الطلاء ومعايير الجودة.

- كل أنبوب معلمة بأرقام الدفعات ومواصفات الطلاء وتفاصيل الشركة المصنعة لـ التتبع الكامل.

- الأنابيب بعد ذلك تغليفها وتعبئتها وتجهيزها للشحن.

لماذا تفضل أنابيب مغلفة بإيبوكسي قطران الفحم؟

✔ مقاومة ممتازة للمواد الكيميائية والتآكل والأضرار الميكانيكية

✔ مثالية للتطبيقات تحت الأرض والغاطسة والصناعية

✔ عمر افتراضي أطول مقارنة بالطلاءات التقليدية

✔ حل اقتصادي للبيئات القاسية

شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة يضمن امتثال صارم لمعايير ISO وAPI وASTM لـ أنابيب مغلفة بإيبوكسي قطران الفحم عالية الجودة.

تطبيقات أنبوب مغلف بإيبوكسي قطران الفحم واستخداماته الصناعية

أين تستخدم أنابيب مغلفة بإيبوكسي قطران الفحم؟

تُستخدم أنابيب مغلفة بإيبوكسي قطران الفحم على نطاق واسع في الصناعات التي تتطلب مقاومة فائقة للتآكل والكشط والمتانة.

| الصناعة | التطبيق | لماذا أنابيب مغلفة بإيبوكسي قطران الفحم؟ |

|---|---|---|

| صناعة النفط والغاز | خطوط الأنابيب تحت الأرض والغاطسة | مقاومة عالية للنفط والغاز والمواد الكيميائية |

| نقل المياه | خطوط أنابيب مياه الشرب ومياه الصرف الصحي | مقاوم للتآكل، آمن لمياه الشرب |

| البحرية والبحرية | خطوط الأنابيب تحت سطح البحر، وهياكل السفن | مقاومة لمياه البحر والبيئات البحرية |

| أنظمة الصرف الصحي والصرف الصحي | خطوط نقل الصرف الصحي | يمنع التآكل الناتج عن مياه الصرف العدوانية |

| التطبيقات الصناعية | المعالجة الكيميائية، البيئات عالية التآكل | يتحمل المواد الكيميائية القوية والتآكل |

لماذا يُفضل طلاء إيبوكسي قطران الفحم للتطبيقات تحت الأرض والبحرية؟

✔ يتحمل الظروف البيئية القاسية

✔ يوفر مقاومة ممتازة للتآكل والمواد الكيميائية

✔ مقاوم للكشط والصدمات والإجهاد الميكانيكي

✔ موردو أنابيب الفولاذ المجلفنة حلزونياً & مصدِّروها

مجموعة كانغتشو للأنابيب الفولاذية الحلزونية الإمدادات أنابيب مغلفة بإيبوكسي قطران الفحم المخصصة لـ النفط والغاز، نقل المياه، أنظمة الصرف الصحي، والتطبيقات الصناعية.

أنبوب مغلف بإيبوكسي قطران الفحم مقابل الطلاءات المضادة للتآكل الأخرى

عند تحديد الطلاءات المضادة للتآكل، من المهم المقارنة بين طلاء إيبوكسي قطران الفحم مع الطلاءات الشائعة الأخرى.

| الميزة | 3300–4500 | الأنابيب المغطاة بالإيبوكسي المترابط بالاندماج (FBE) | أنابيب مغلفة بالبولي إيثيلين ثلاثي الطبقات (3LPE) | أنابيب مطلية بـ3LPE عالية الجودة بأسعار تنافسية |

|---|---|---|---|---|

| مقاومة التآكل | ممتاز | عالية | عالية جداً | عالية |

| مقاومة التآكل | عالية جداً | معتدل | عالية | عالية جداً |

| مقاومة المواد الكيميائية | ممتاز | عالية | معتدل | عالية |

| مقاومة درجات الحرارة | عالية | معتدل | عالية | عالية |

| أفضل حالة استخدام | خطوط الأنابيب تحت الأرض، وأنظمة الصرف الصحي، والتطبيقات البحرية | خطوط أنابيب النفط والغاز والتطبيقات البحرية | خطوط الأنابيب تحت الأرض، المناطق شديدة التأثير | تتضمن تطبيق |

المزايا الرئيسية لأنابيب مغلفة بإيبوكسي قطران الفحم

✔ مقاومة فائقة للتآكل والمواد الكيميائية

✔ الأفضل للتطبيقات تحت الأرض والصرف الصحي والبحرية

✔ شديدة المتانة تقلل تكاليف الصيانة

✔ يوفر مقاومة ممتازة للصدمات والكشط

موردو ومصدرو أنابيب مغلفة بإيبوكسي قطران الفحم

إذا كنت تبحث عن استيراد أنابيب مغلفة بإيبوكسي قطران الفحمالعمل مع مورد موثوق يضمن الجودة، والأسعار التنافسية، والتسليم في الوقت المناسب.

أبرز مصدري الصين لأنابيب مغلفة بإيبوكسي قطران الفحم

| اسم الشركة | الموقع | الطاقة الإنتاجية السنوية |

|---|---|---|

| شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة | خبي، الصين | 400,000 طن |

| مجموعة باوستيل | شنغهاي، الصين | أكثر من 500,000 طن |

| شركة تيانجين لأنابيب الصلب | تيانجين، الصين | 300,000 طن |

لماذا تختار مجموعة أنابيب الصلب الحلزوني في تشانغتشو لأنابيب مغلفة بإيبوكسي قطران الفحم؟

✔ 27 عاماً من الخبرة في تصنيع الأنابيب الفولاذية

✔ طلاءات معتمدة من ISO 9001 وAPI 5L وASTM معتمدة من ASTM

✔ 13 خط إنتاج، تغطي الأقطار من 219 مم إلى 3500 مم

✔ الطلاءات المخصصة والمعالجات المضادة للتآكل متوفرة

✔ شبكة تصدير قوية إلى أمريكا الشمالية وأوروبا وآسيا

بالنسبة لـ أنابيب مغلفة بإيبوكسي قطران الفحم عالية الجودة, شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة هو مورد موثوق به.

أسئلة شائعة: أنبوب مغلف بإيبوكسي قطران الفحم

| سؤال | الإجابة |

|---|---|

| ما هي استخدامات أنبوب مغلف بإيبوكسي قطران الفحم؟ | تستخدم ل خطوط أنابيب النفط والغاز، والمنشآت البحرية، وأنظمة الصرف الصحي، والتطبيقات الصناعية. |

| كيف يقارن طلاء إيبوكسي قطران الفحم بطلاءات FBE؟ | يوفر إيبوكسي قطران الفحم مقاومة أفضل للكشط، بينما يقدم FBE التصاقًا ومرونة فائقين. |

| ما هي العمر الافتراضي لأنبوب مغلف بإيبوكسي قطران الفحم؟ | 30-60 عاماً، حسب التعرض البيئي والصيانة. |

| من هو المورد الأفضل؟ | شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة هي مورد رائد مع طلاءات معتمدة من ISO وAPI. |

| ما هو سعر الطن في عام 2025؟ | تتراوح الأسعار من 1,600 إلى 1,600 إلى 1,600 إلى 4,200 للطنحسب الحجم وسُمك الطلاء. |

| هل طلاء إيبوكسي قطران الفحم آمن لأنابيب المياه؟ | نعم، يُستخدم على نطاق واسع في أنظمة المياه البلدية والصرف الصحي. |

| كيف يتم اختبار هذه الأنابيب؟ | يضمن التصاق الطلاء وقياس السُمك واختبارات الضغط الهيدروستاتيكي الامتثال للجودة. |

| هل يمكن استخدام أنابيب مغلفة بإيبوكسي قطران الفحم في البيئات البحرية؟ | نعم، فهي توفر مقاومة ممتازة لمياه البحر والظروف البحرية القاسية في البحر. |

الأفكار النهائية

أنابيب مغلفة بإيبوكسي قطران الفحم تستخدم على نطاق واسع في النفط والغاز، أنظمة الصرف الصحي، البحرية، والتطبيقات الصناعية بسبب مقاومة فائقة للتآكل، والكشط، وعمر افتراضي طويل.

بالنسبة لـ أنابيب مغلفة بإيبوكسي قطران الفحم عالية الجودة, شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة هو الخيار الأفضل في عام 2025!

تحتاج إلى اقتباس أو أكثر التفاصيل الفنية? اتصل بنا مجموعة كانغتشو للأنابيب الفولاذية الحلزونية اليوم!