مصنّع أنابيب الصلب الحلزوني الملحوم

توافر المخزون مخزون كبير جاهز للشحن الفوري.

ضمان الجودة

يخضع كل أنبوب لاختبارات صارمة، بما في ذلك الفحص بالموجات فوق الصوتية والاختبار الهيدروستاتيكي والفحص التلفزيوني الصناعي، مما يضمن الامتثال لشهادات API 5L وشهادات الاتحاد الأوروبي.

خدمة OEM & ODM

نحن نقدم حلولاً قابلة للتخصيص بالكامل، بدءاً من اختيار المواد إلى الطلاءات والأبعاد المتخصصة، مما يلبي احتياجات الصناعة المتنوعة.

التوصيل في الوقت المحدد

من خلال 13 خط إنتاج، و4 خطوط مضادة للتآكل، وقواعد تصنيع متعددة، نضمن كفاءة الإنتاج والتسليم في الوقت المناسب للأسواق العالمية.

شارك هذا المنتج

الحل الشامل

بدءاً من التصميم وحتى الإنتاج، نقدم حلولاً مخصصة للأنابيب الفولاذية الحلزونية، بما في ذلك الطلاءات المضادة للتآكل وضمان الجودة.

نطاق واسع الحجم

تتراوح أنابيبنا من Φ219 مم إلى Φ3500 مم، مع خيارات متنوعة لسُمك الجدار، بما يلبي متطلبات المشاريع المتنوعة.

المعايير الدولية

منتجاتنا معتمدة وفقًا لمعايير API 5L وSY/T وGB/T، وهي تلبي لوائح الصناعة العالمية من حيث الموثوقية والمتانة.

نظرة عامة على أنبوب الصلب الحلزوني الملحوم

A أنابيب الصلب الملحومة الحلزونية، المعروف أيضًا باسم أنبوب اللحام قوس تحت الماء الحلزوني (HSAW)، يُصنع عن طريق لف شريط الصلب الساخن المتدحرج حلزونيًا ولحام الخياطة باستخدام طرق اللحام قوس تحت الماء (SAW). هذه العملية تنتج أنابيب عالية القوة وقطر كبير مثالي ل نقل النفط والغاز ونقل المياه والأكوام والتطبيقات الهيكلية وأكثر.

الميزات الرئيسية لأنبوب الصلب الحلزوني الملحوم

✔ قدرات قطر كبير (حتى 3500 مم)

✔ قوة عالية ومتانة للتطبيقات الصناعية

✔ اقتصادي التكلفة مقارنة بالأنابيب السلسة

✔ سلامة لحام ممتازة بلحام قوس تحت الماء (SAW)

✔ مثالي لخطوط الأنابيب طويلة المدى والمشاريع الهيكلية

في هذا الدليل، سنستعرض كل شيء عن أنابيب الصلب الملحومة الحلزونيةبما في ذلك عمليات التصنيع والمواصفات والتطبيقات واتجاهات الأسعار والمزايا.

أبرز مصنّعي أنابيب الصلب الحلزوني الملحوم

تتبع مُصنِّع موثوق يضمن صلب عالي الجودة ولحام دقيق وامتثال للمعايير الدولية. فيما يلي بعض من مصنّعو أنابيب الصلب الحلزوني الملحوم الرائدون في 2025:

1. Cangzhou Spiral Steel Pipes Group Co., Ltd.

✔ 27 عاماً من الخبرة في تصنيع أنابيب الصلب

✔ 13 خط إنتاج لـ Φ219-Φ3500 مم الأنابيب الملحومة الحلزونية

✔ الطاقة الإنتاجية السنوية: 400,000 طن

✔ منتجات معتمدة بموجب ISO 9001 وAPI 5L وASTM وGB/T

✔ طلاءات متخصصة: 3LPE وFBE وراتنج الفحم الإيبوكسي والبولي يوريثان

2. Baosteel Group (الصين)

A أكبر منتج للصلب متخصصون في أنابيب حلزونية ملحومة عالية القوة لنقل النفط والغاز والمياه.

3. Jindal SAW Ltd (الهند)

شهادات ISO و JIS 3457 الأنابيب الملحومة الحلزونية لـ البنية التحتية والأكوام والتطبيقات الصناعية.

4. تيناريس (عالمي)

شركة تصنيع عالمية المستوى تقدم أنابيب HSAW عالية الأداء لخطوط الأنابيب البحرية وعالية الضغط.

5. Welspun Corp Ltd (الهند)

A علامة تجارية معترف بها عالميًا توفير أنابيب حلزونية ملحومة كبيرة القطر للاستخدام الهيكلي والصناعي.

يضمن كل من هذه الشركات المصنعة الامتثال الصارم لمعايير الصناعةضماناً لـ متانة وأداء عاليان.

أنبوب الصلب الحلزوني الملحوم مقابل أنابيب الصلب الأخرى

اختيار المناسب نوع أنبوب الصلب يعتمد على التطبيق والتكلفة والمتانة وطريقة التصنيع. إليك الطريقة أنابيب الصلب الملحومة الحلزونية يُقارن بأنواع الأنابيب الأخرى:

| الميزة | أنبوب الصلب الحلزوني الملحوم (HSAW) | أنبوب ملحوم طولي (LSAW) | أنابيب الصلب غير الملحومة |

|---|---|---|---|

| عملية التصنيع | لحام حلزوني لشرائط الصلب | لحام طولي لوحات الصلب | بدون لحام (مبثوق من سبيكات الصلب) |

| مثالية للنفط والغاز ونقل المياه والتطبيقات الصناعية | عالية | عالية جداً | عالية للغاية |

| نطاق القطر | يتقلب بناءً على عوامل مثل | متوسطة إلى كبيرة | صغير إلى متوسط |

| سُمك الجدار | متوسطة إلى سميكة | سميك | رقيقة إلى متوسطة |

| التكلفة | فعالة من حيث التكلفة | أغلى تكلفة | أعلى تكلفة |

| أفضل حالة استخدام | تتوافق مع معايير API 5L وISO | خطوط الأنابيب عالية الضغط والنفط والغاز | تطبيقات عالية الحرارة والدقة |

لماذا تختار أنابيب الصلب الحلزوني الملحوم؟

✔ فعالة من حيث التكلفة للتطبيقات ذات الأقطار الكبيرة

✔ مثالية لخطوط الأنابيب المائية والأكوام والاستخدام الهيكلي

✔ قوة لحام عالية ومتانة

✔ عملية تصنيع أسهل للأنابيب الأطول

سعر أنبوب الصلب الحلزوني الملحوم للطن في 2025

سعر أنابيب الصلب الملحومة الحلزونية ، يضمن هذا المعيار قطر الأنبوب وسماكة الجدار ودرجة الصلب وخيارات الطلاءقوة عالية، مقاومة للتآكل، ومتانة

| قطر الأنبوب (مم) | سُمك الجدار (مم) | درجة الفولاذ | سعر الطن (بالدولار الأمريكي) |

|---|---|---|---|

| 219 – 600 | 6 – 10 | API 5L، Q235B | 800−800 – 800−1,200 |

| 610 – 1200 | 8 – 14 | X42 – X60 | 1,100−1,100 – 1,100−1,600 |

| 1220 – 1800 | 10 – 18 | X65 – X80 | 1,500-1,500 - 1,500-2,200 |

| 2000 – 3500 | 12 – 25 | X80 – X100 | 2,000−2,000 – 2,000−3,000 |

العوامل المؤثرة في السعر:

✔ درجة الفولاذ – الصلب عالي الدرجة يكلف أكثر بسبب القوة والمتانة المحسّنتين.

✔ قطر الأنبوب وسُمك الجدار – الأنابيب الأكبر سماكة تتطلب مواد خام أكثر، مما يزيد التكاليف.

✔ عملية لحام وتصنيع أنابيب ملحومة حلزونيًا CSA Z245.1 – 3LPE وFBE وغيرها من الطلاءات تضيف إلى السعر.

✔ الفوائد - تحصل طلبات الكمية الكبيرة على أسعار أفضل.

تقدم مجموعة أنابيب الصلب الحلزونية الحلزونية من تشانجتشو أنابيب الصلب الحلزوني الملحوم عالية الجودة بأسعار تنافسية.

عملية تصنيع أنبوب الصلب الحلزوني الملحوم ومراقبة الجودة

كيف يتم تصنيع أنبوب الصلب الحلزوني الملحوم؟

إن عملية تصنيع أنبوب حلزوني ملحوم تشمل تشكيل شريط صلب مستمر إلى أفضل مصدّري الصين لأنابيب ملحومة حلزونيًا CSA Z245.1 و لحام الدرز باستخدام لحام القوس المغمور (SAW). هذه العملية فعالة، وفعالة من حيث التكلفة، ومثالية للأنابيب ذات القطر الكبير. فيما يلي تفصيل مفصل لعملية تصنيع أنابيب الفولاذ المجلفنة حلزونياً خطوة بخطوة:

1. اختيار لفائف الصلب & التحضير

- عالية الجودة لفائف فولاذ مجلفن ساخن يتم اختيارها بناءً على المواصفات والمعايير المطلوبة.

- يُطعَم الشريط الفولاذي في آلة التشكيل تُفكّ، تُسطّح، وتُقلَم لإزالة الحواف غير المنتظمة.

2. عملية التشكيل الحلزوني

- يُطعَم الشريط الفولاذي في آلة التشكيل ويُشكَّل حلزونياً. حيث يتم ملفوفة على شكل حلزوني.

- محاذاة الحواف بدقة لضمان خياطة متسقة لللحام.

3. عملية اللحام تحت الغاطس (SAW)

- يُطبق لحام تحت الغاطس داخلي وخارجي (SAW) لإنشاء خياطة لحام قوية خالية من العيوب.

- تشمل عملية اللحام حماية بالفلكسإرشادات CSA Z245.1 اختراق عميق وقوة عالية.

4. الفحص بالموجات فوق الصوتية والأشعة

- تخضع خياطات اللحام لفحص بالموجات فوق الصوتية والأشعة السينية لاكتشاف أي عيوب داخلية أو خارجية.

- يتم إصلاح أي عيوب مكتشفة أو رفضها إنتاج عالي الجودة لضمان 5. اختبار الضغط الهيدروستاتيكي.

اختبار الضغط الهيدروستاتيكي

- يخضع كل أنبوب لـ أداء محكم الإغلاق تحت ضغط عالٍ للتحقق من الأنابيب التي تنجح في الاختبار.

- معتمدة للتطبيقات عالية الضغط 6. القطع & التشذيب.

يتم قطع الأنابيب باستخدام

- آلات القطع الآلية القطع بالأطوال المطلوبة باستخدام تُشذَّب حواف الأنابيب.

- لضمان لحام صحيح أثناء التركيب لضمان لماذا تُفضَّل أنابيب الفولاذ المجلفنة حلزونياً؟.

7. الطلاء والمعالجة المضادة للتآكل

- يمكن طلاء الأنابيب بما يلي طلاءات 3LPE، أو FBE، أو الإيبوكسي بقطران الفحم، أو البولي يوريثان لـ مقاومة محسنة للتآكل.

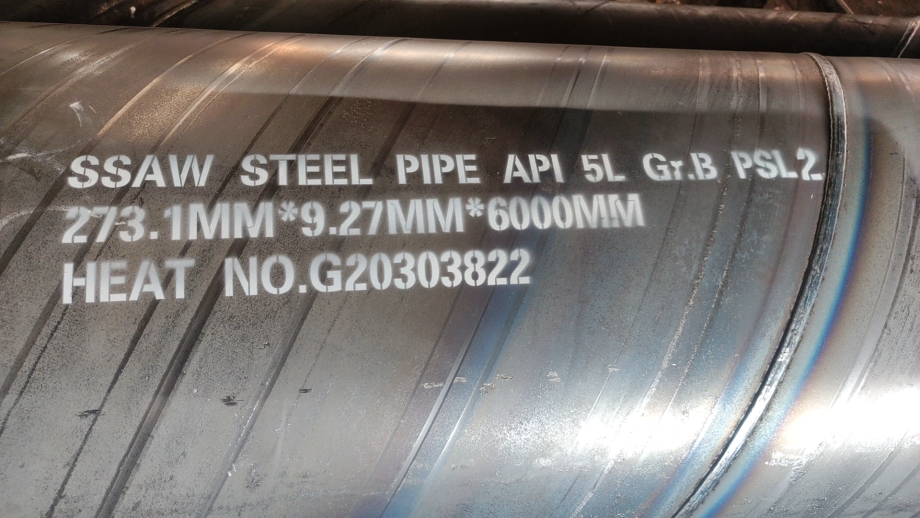

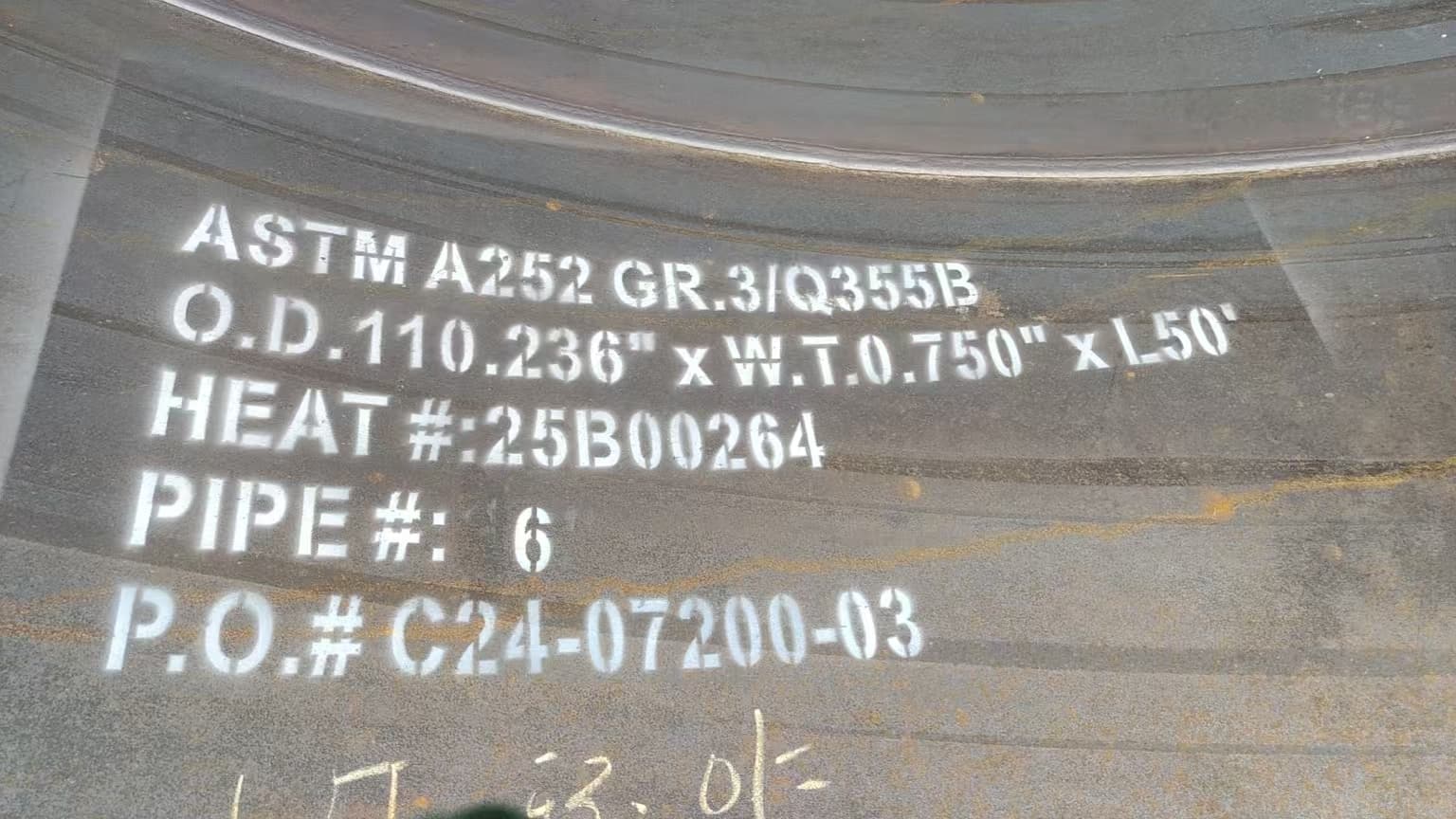

8. الفحص النهائي والتعبئة والتغليف

- الأنابيب يتم فحصها بصريًا ووضع علامات عليها وتغليفها وفقًا لمتطلبات العميل.

- كل أنبوب تختم بأرقام الدفعات والمواصفات وبيانات الشركة المصنعة لـ التتبع الكامل.

يتم تصنيعها بأقطار كبيرة، مما يجعلها مثالية لخطوط الأنابيب

✔ لحام عالي القوة داخلياً وخارجياً بتقنية SAW

✔ إنتاج فعال من حيث التكلفة مقارنة بالأنابيب السلسة أو LSAW

✔ تطبيقات واسعة في مشاريع النفط والماء والهياكل

✔ إجراءات مراقبة جودة واختبار صارمة

شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة يتبع أنابيب الفولاذ المجلفنة حلزونياً عالية الجودة لضمان تطبيقات أنابيب الفولاذ المجلفنة حلزونياً & استخداماتها الصناعية.

تُستخدَم أنابيب الفولاذ المجلفنة حلزونياً على نطاق واسع في

أين تستخدم أنابيب الصلب الملحومة حلزونيًا؟

الصناعات التي تتطلب خطوط أنابيب عالية القوة وقطر كبير خطوط النفط والغاز لمسافات طويلة.

| الصناعة | التطبيق | لماذا أنابيب الصلب الملحومة حلزونيًا؟ |

|---|---|---|

| صناعة النفط والغاز | فعالة من حيث التكلفة، متينة، ومقاومة للضغط العالي | خطوط مياه الشرب والصرف الصحي |

| نقل المياه | مقاومة للتآكل ومحكمة الإغلاق | الجسور والمباني والبنية التحتية |

| التطبيقات الهيكلية | سعة تحمل عالية للأحمال | الأساسات والخوازيق |

| الهياكل البحرية وإنشاء الموانئ | قوية، مقاومة للصدمات، ومتينة | الحفر والأعمال البحرية |

| خطوط الأنابيب تحت الماء وعمليات الحفر | طلاءات مقاومة للمياه المالحة متوفرة | لماذا تُعد أنابيب المجلفنة حلزونياً مثالية لنقل المياه؟ |

محكمة الإغلاق ومقاومة للتآكل

✔ للمتانة طويلة الأمد قدرة على الأقطار الكبيرة

✔ تسمح بتدفق المياه الفعال يمكن طلاؤها بـ3LPE أو FBE لتعزيز الحماية

✔ أنابيب الفولاذ المجلفنة حلزونياً المخصصة

مجموعة كانجتشو للأنابيب الفولاذية الحلزونية تورد مشاريع النفط والغاز ونقل المياه والخوازيق والبنية التحتية لـ طلاء أنابيب الفولاذ المجلفنة حلزونياً & معالجة مضادة للتآكل.

، يمكن طلاء أنابيب الفولاذ المجلفنة حلزونياً بمختلف

لضمان أداء يدوم طويلاًأنظمة الصرف الصحي وخطوط الأنابيب الصناعية العلاجات المضادة للتآكل.

| عملية لحام وتصنيع أنابيب ملحومة حلزونيًا CSA Z245.1 | مقاومة التآكل | أفضل التطبيقات |

|---|---|---|

| طلاء 3LPE | عالية جداً | خطوط الأنابيب تحت الأرض، النفط والغاز |

| طلاء FBE (الإيبوكسي المترابط بالاندماج) | عالية | خطوط أنابيب المياه والتطبيقات البحرية |

| طلاء الإيبوكسي بقطران الفحم الإيبوكسي | ممتاز | لماذا يكون الطلاء أساسياً لأنابيب المجلفنة حلزونياً؟ |

| طلاء البولي يوريثان | عالية | البيئات البحرية وذات درجات الحرارة العالية |

يطيل عمر خطوط الأنابيب

✔ يمنع التآكل الناتج عن الماء والمواد الكيميائية والتعرض البيئي

✔ يقلل تكاليف الصيانة والتشغيل

✔ موردو أنابيب الفولاذ المجلفنة حلزونياً & مصدِّروها

الإيبوكسي المركّب بالاندماج (FBE)، 3LPE، وبطانة الملاط الإسمنتي خدمات الطلاء المخصّصة لمقابلة المتطلبات الخاصة بالصناعة.

استيراد أنابيب مجلفنة

إذا كنت تبحث عن حلزونياً الفولاذ أفضل مصدِّري الصين لأنابيب الفولاذ المجلفنة حلزونياًالعمل مع مورد موثوق يضمن الجودة، والأسعار التنافسية، والتسليم في الوقت المناسب.

لماذا تختار مجموعة أنابيب الفولاذ الحلزوني في تشانغتشو لأنابيب الفولاذ المجلفنة حلزونياً؟

| اسم الشركة | الموقع | الطاقة الإنتاجية السنوية |

|---|---|---|

| شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة | خبي، الصين | 400,000 طن |

| مجموعة باوستيل | شنغهاي، الصين | أكثر من 500,000 طن |

| شركة تيانجين لأنابيب الصلب | تيانجين، الصين | 300,000 طن |

أنابيب الفولاذ المجلفنة حلزونياً عالية الجودة

✔ 27 عاماً من الخبرة في تصنيع الأنابيب الفولاذية

✔ منتجات معتمدة من ISO 9001 و API 5L و ASTM

✔ 13 خط إنتاج، تغطي الأقطار من 219 مم إلى 3500 مم

✔ الطلاءات المخصصة والمعالجات المضادة للتآكل متوفرة

✔ شبكة تصدير قوية إلى أمريكا الشمالية وأوروبا وآسيا

بالنسبة لـ الأسئلة الشائعة: أنبوب الفولاذ المجلفن حلزونياً, شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة هو مورد موثوق به.

ما هي استخدامات أنبوب الفولاذ المجلفن حلزونياً؟

| سؤال | الإجابة |

|---|---|

| خطوط الأنابيب النفطية والغازية، والخوازيق، ونقل المياه، والتطبيقات الهيكلية | تستخدم ل كيف يقارن أنبوب مجلفن حلزونياً بأنبوب LSAW؟. |

| أنابيب المجلفنة حلزونياً أكثر فعالية من حيث التكلفة، بينما تتمتع أنابيب LSAW بقوة أعلى للتطبيقات عالية الضغط | ما هو عمر أنبوب مجلفن حلزونياً؟. |

| من 800 إلى 3000 دولار للطن | 40-80 عامًا، حسب الطلاء والتعرض البيئي. |

| من هو المورد الأفضل؟ | شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة هي مورد رائد مع منتجات معتمدة من ISO و API. |

| ما هو سعر الطن في عام 2025؟ | تتراوح الأسعار من هل يمكن استخدام أنابيب مجلفنة حلزونياً في التطبيقات عالية الضغط؟حسب الحجم ودرجة الفولاذ. |

| نعم، لكن أنابيب LSAW مفضلة للظروف عالية الضغط الشديدة | ما هي الطلاءات المتوفرة لأنابيب مجلفنة حلزونياً؟. |

| هل أنابيب مجلفنة حلزونياً مناسبة للمشاريع البحرية؟ | طلاءات 3LPE، وFBE، وإيبوكسي قطران الفحم، والبولي يوريثان. |

| نعم، تُستخدم على نطاق واسع في خطوط الأنابيب النفطية والغازية البحرية | نقل المياه، والخوازيق، والنفط والغاز، والتطبيقات الهيكلية. |

الأفكار النهائية

أنابيب الصلب الملحومة الحلزونية تستخدم على نطاق واسع في أنابيب الفولاذ المجلفنة حلزونياً عالية الجودة بسبب 4. Baosteel Group (الصين).

بالنسبة لـ مصنِّع أنابيب مطلية بـ3LPE - تسانغلو, شركة مجموعة تشانغتشو للأنابيب الفولاذية الحلزونية المحدودة هو الخيار الأفضل في عام 2025!

تحتاج إلى اقتباس أو أكثر التفاصيل الفنية? اتصل بنا مجموعة كانغتشو للأنابيب الفولاذية الحلزونية اليوم!